Iron alloy grain casting machine

A ferroalloy and granulator technology, which is applied in the field of cast iron machines, can solve the problems of motion parameters, precision not meeting requirements, mold specifications not suitable for ferroalloy blocks, large volume of pig iron and large monomer weight, etc., to achieve consistent weight and reduce operating area. , the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

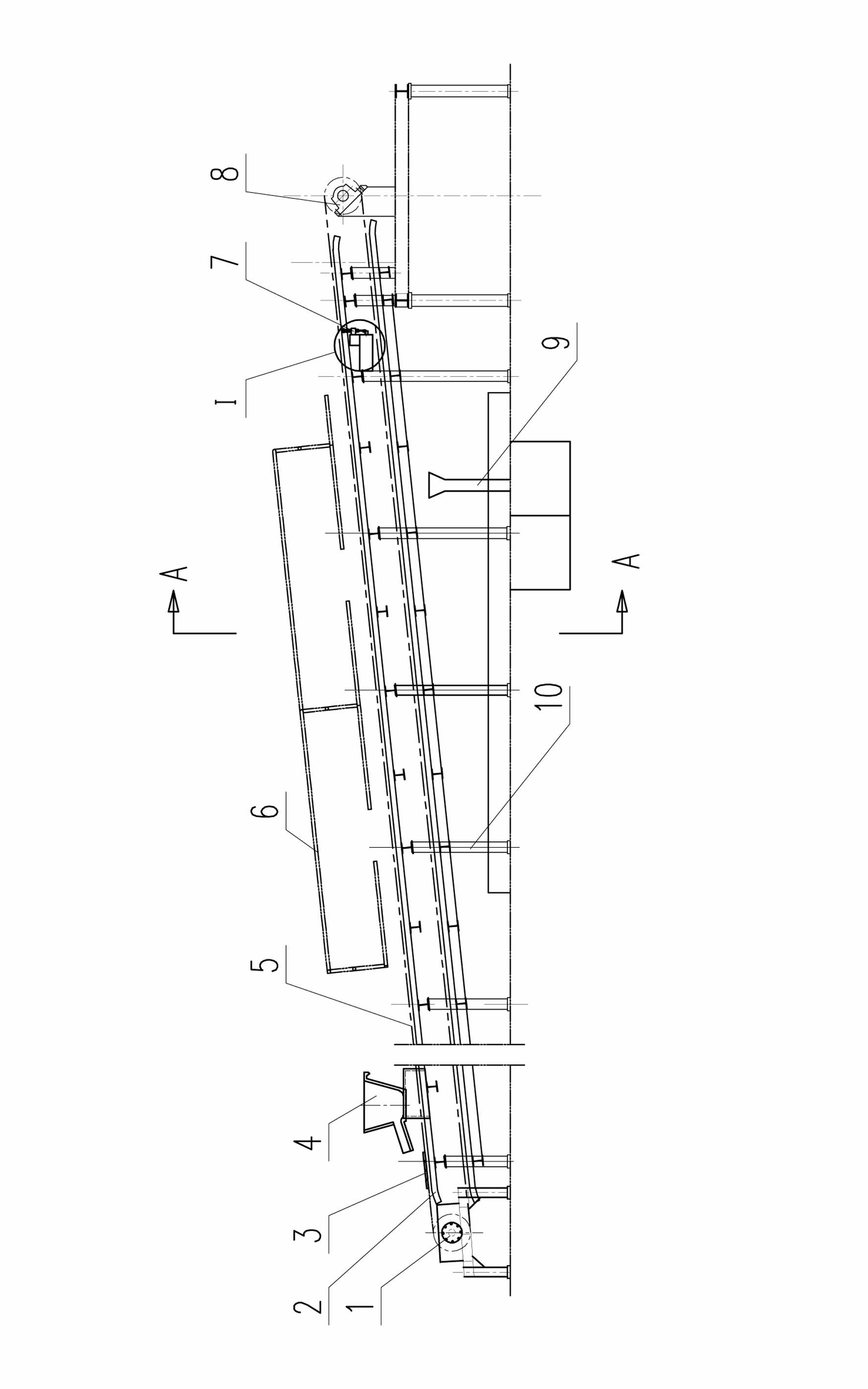

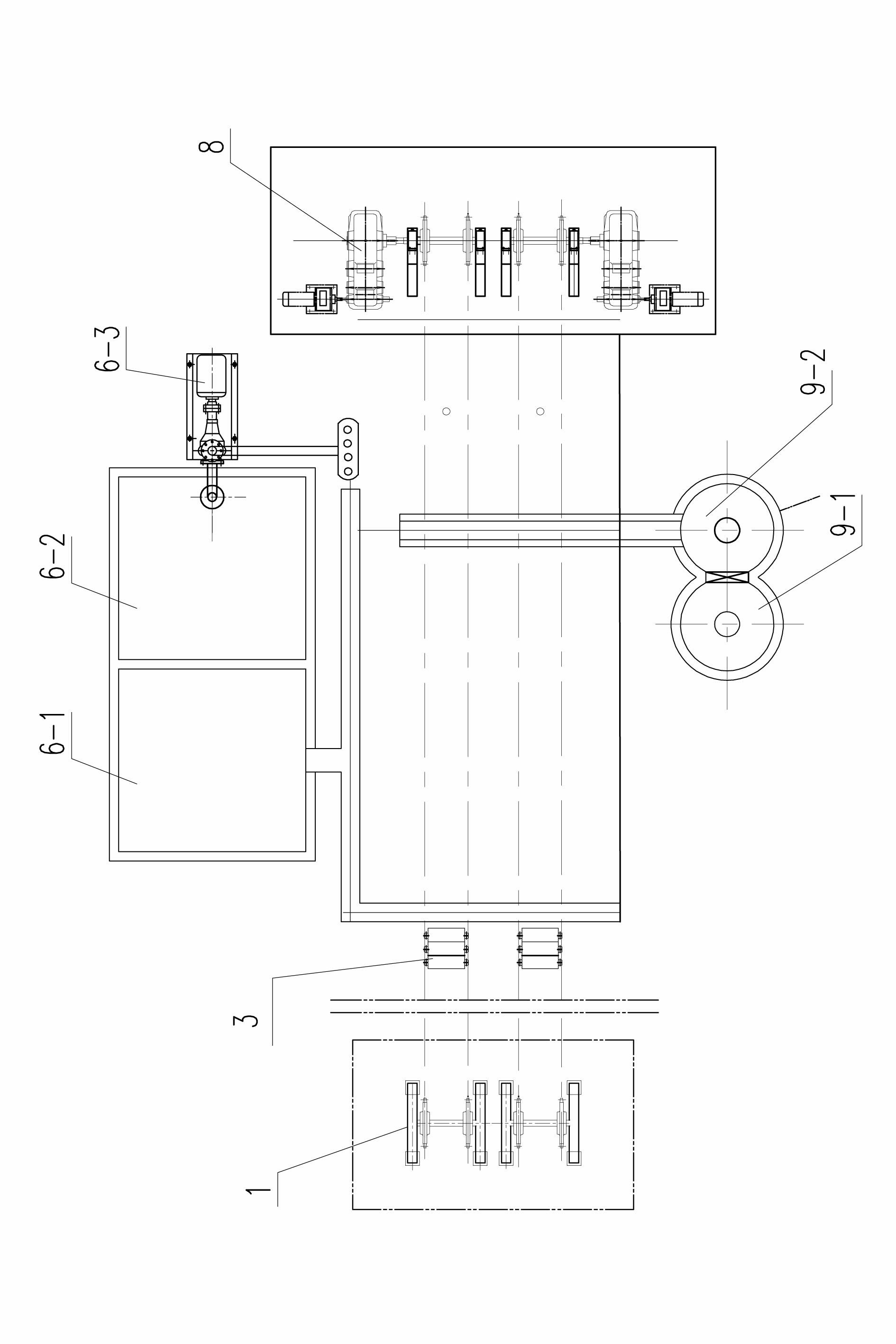

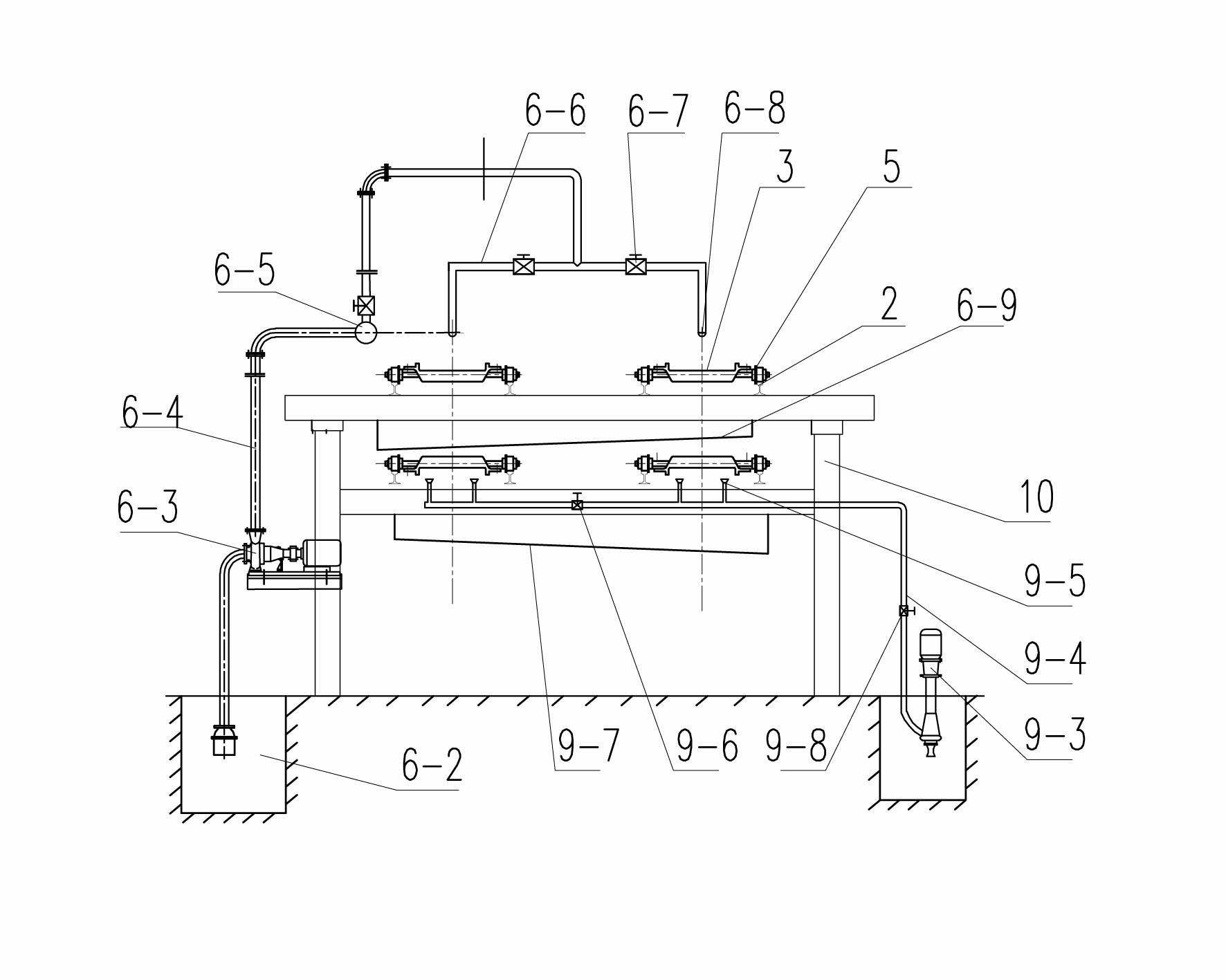

[0040] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] like figure 1 , 2 , Shown in 3, the ferroalloy casting machine of the present invention is characterized in that by the chain-type inclined conveyor, a group of cast-granule molds 3 which are connected with this chain-type inclined conveyor and arranged at the same interval successively are arranged in this chain-type inclined conveyor. The spraying mechanism 9 below the inclined conveyor, the water cooling mechanism 6 above the chain inclined conveyor, the vibration device 7 at the head of the chain inclined conveyor, and the tail of the chain inclined conveyor ferroalloy liquid pouring heat preservation chute 4, the cast grain finished product receiving hopper arranged under the said shocking device 7 and the electrical connection connected with the said chain type inclined conveyor, the spraying mechanism, the water cooling mechanism ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com