Argon-blowing prefabricated member for continuous casting tundish cover

A technology of continuous casting tundish and prefabricated parts, which is applied in the direction of manufacturing tools, casting equipment, casting melt containers, etc. It can solve the problems of time-consuming and labor-intensive costs, deformation of the tundish cover, and erosion of the tundish cover, so as to ensure the metallurgical effect , Reduced replacement frequency and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

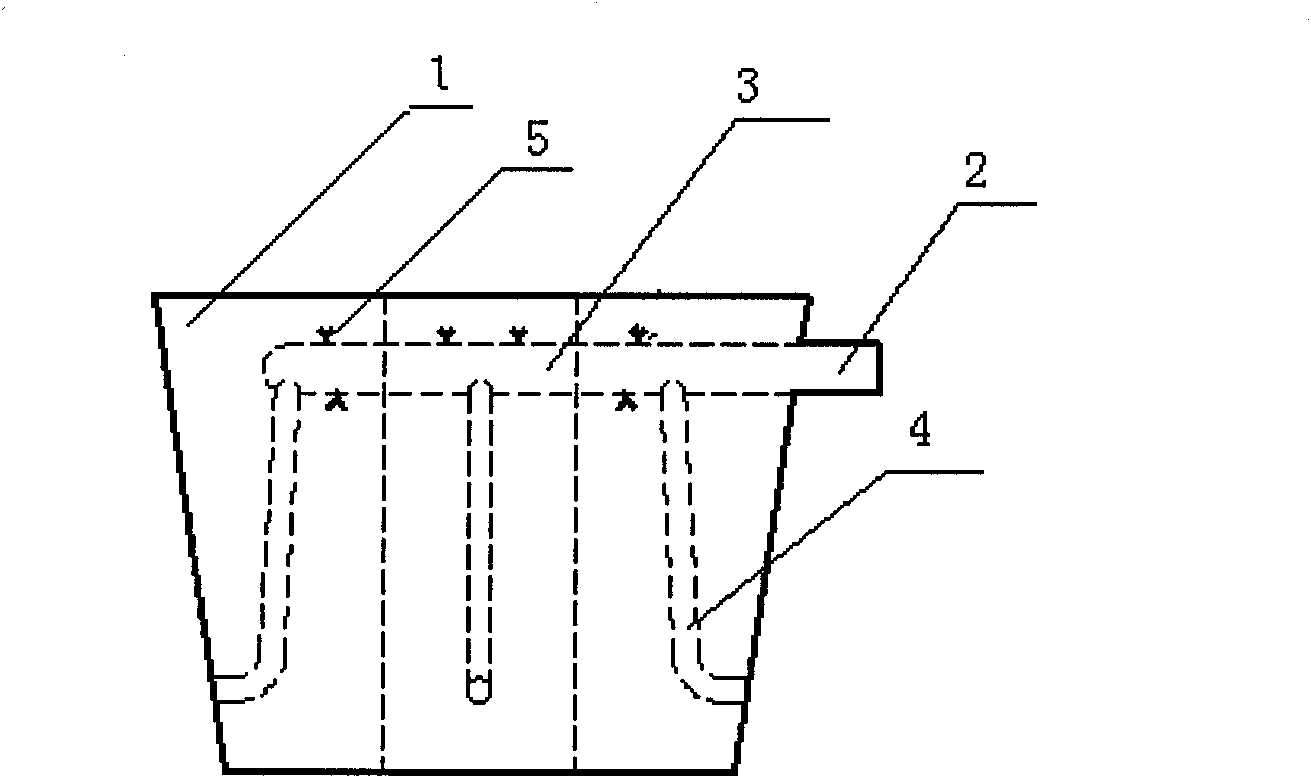

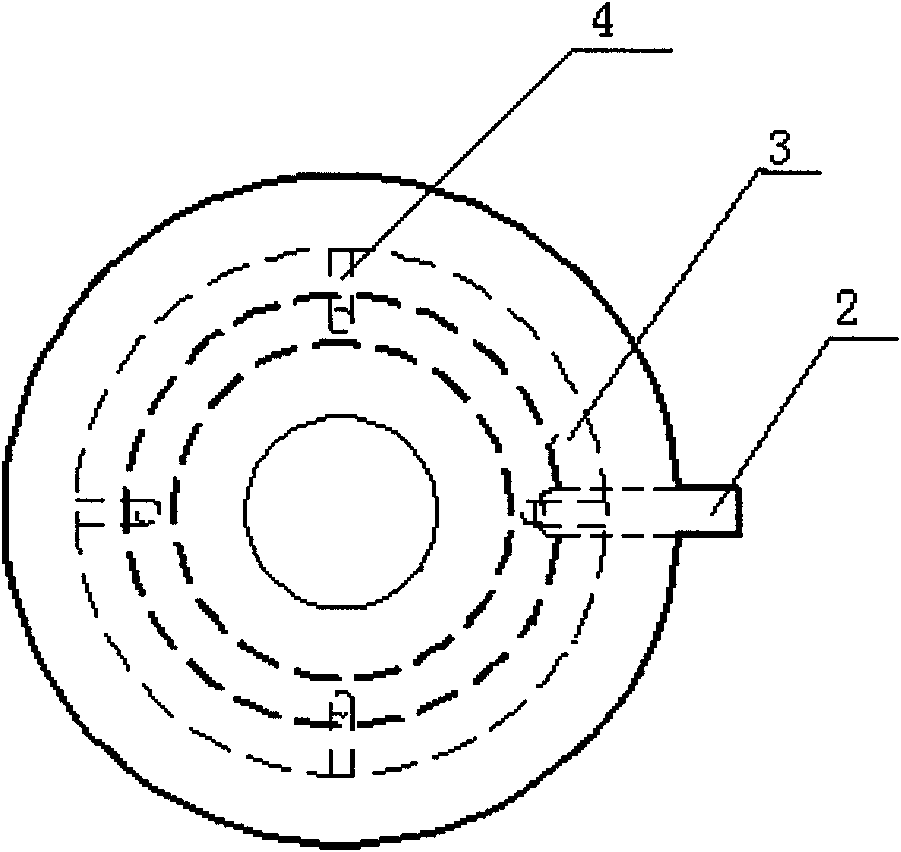

[0037] Such as figure 1 , figure 2 As shown, an argon-blowing preform for continuous casting tundish cover includes a preform body 1, which is hollow, and a ventilation duct is arranged in the preform body 1, and the ventilation duct includes an upper annular channel 3 and a branch channel 4 that communicates with the annular channel 3 and extends downwards. The upper part of the preform body 1 is provided with a vent hole 2 that communicates with the vent pipe. The shape of the preform body 1 is a frustum of a cone whose upper base radius is greater than that of the lower base. The end of the branch channel 4 is bent toward the side of the prefabricated body 1, and the bent end is a horizontal outlet, and the outlet is 15 mm away from the bottom surface of the prefabricated body 1. There are 4 branch passages 4, and 1 annular passage.

[0038] There are multiple openings on the annular passage 3, the branch passage 4 communicates with the annular passage 3 through the ope...

Embodiment 2

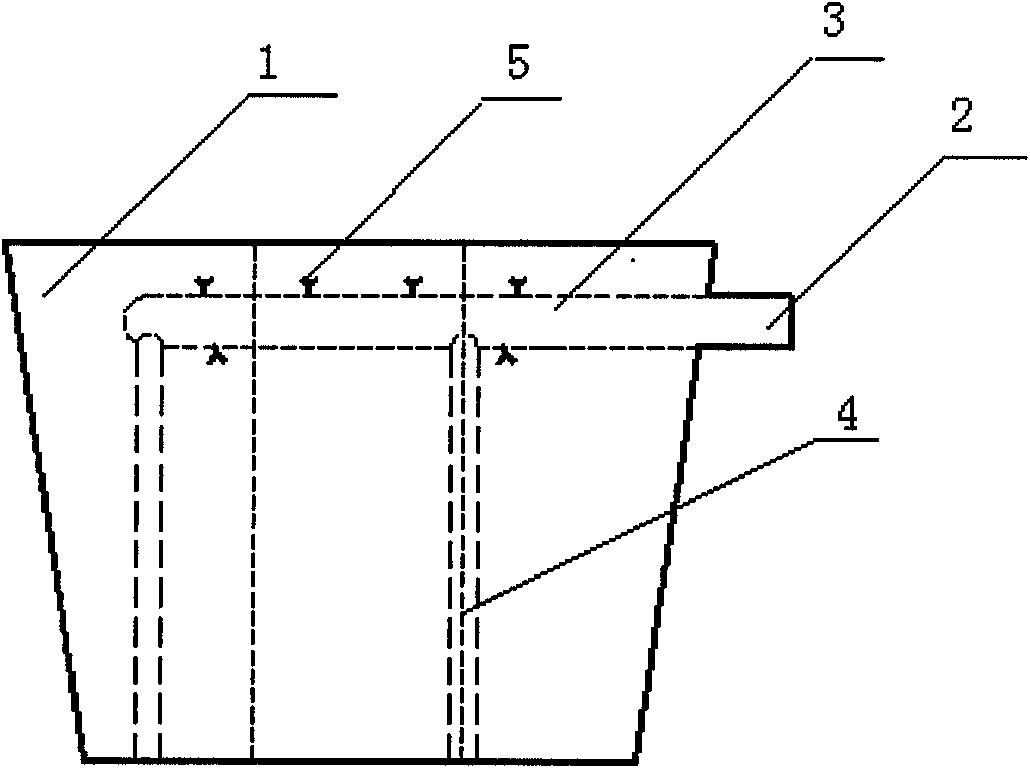

[0047] Such as image 3 , Figure 4 As shown, with the argon-blowing preform for continuous casting tundish cover described in Example 1, the difference is:

[0048] The ends of the branch channels 4 extend vertically downward to the bottom surface of the preform body, and there are three branch channels 4 .

[0049] It is suitable for driving away the air in the tundish before continuous casting and preventing secondary oxidation of molten steel.

[0050] With the present invention, under the same process conditions, the service life of the tundish cover can be improved. The traditional tundish cover is replaced every 200 hours. After using the prefabricated part of the present invention, the tundish cover can be used for more than 450 hours. Compared with the traditional cover, it is more convenient to replace the argon-blown prefabricated part for continuous casting tundish cover of the present invention, save time and labor, and reduce the cost; the replacement time and ...

Embodiment 3

[0054] Such as Figure 5 , Figure 6 As shown, with the argon-blowing preform for continuous casting tundish cover described in Example 1, the difference is:

[0055] The profile of the prefabricated body 1 has a longitudinal section structure of T shape, the end of the branch channel is bent to the side of the prefabricated body, the curved end is a horizontal outlet, the outlet is 20 mm away from the bottom surface of the prefabricated body 1, and there are 3 branched channels 4 .

[0056] With the present invention, under the same process conditions, the service life of the tundish cover can be improved. The traditional tundish cover is replaced every 200 hours. After using the prefabricated part of the present invention, the tundish cover can be used for more than 450 hours. Compared with the traditional cover, it is more convenient to replace the argon blowing prefabricated part for the continuous casting tundish cover of the present invention, save time and labor, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com