Final grinding system of rolling machine in steel slag and mineral slag micropowder production line

A technology of slag micropowder and roller press, applied in grain processing and other directions, can solve the problems of low crushing efficiency, low product specific surface area, coarse powder particle size, etc., and achieve the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

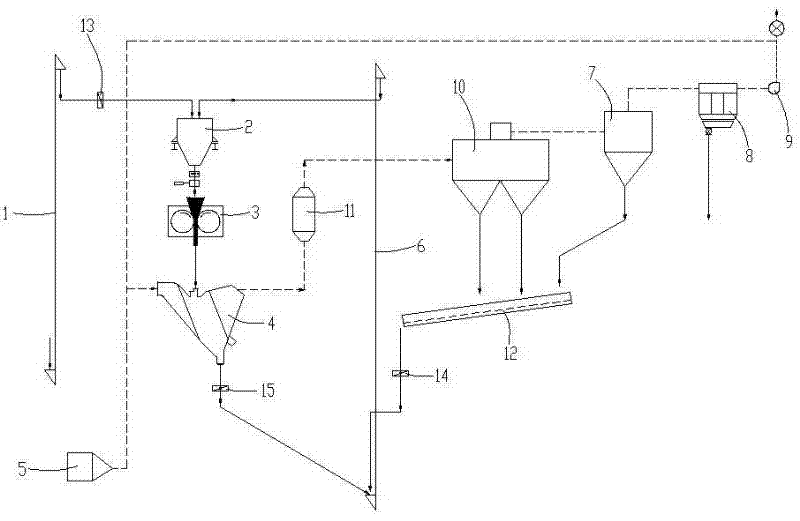

[0009] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0010] Such as figure 1 As shown, the present invention consists of a first bucket elevator 1, a steady-flow weighing bin 2, a roller press 3, a V-type powder separator 4, a high-temperature rapid boiling furnace 5, a second bucket elevator 6, and an ultrafine separator 7 , dust collector 8, fan 9, cyclone dust collector 10, drying pipe 11, chute 12, first iron remover 13, second iron remover 14, third iron remover 15 and belt conveyor. A belt conveyor is set between the first bucket elevator 1 and the steady flow weighing bin 2, and the first bucket elevator 1 feeds materials to the steady flow weighing bin 2 through the belt conveyor, and the first bucket elevator 1 and the steady flow weighing bin 2 are fed. A first iron remover 13 is arranged between the steady flow weighing bins 2 . A roller press 3 is arranged below the steady flow weighing bin 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com