Method for recycling ethylene glycol and acetaldehyde from polyester waste water

A polyester wastewater and ethylene glycol technology, applied in chemical instruments and methods, hydrolysis preparation, water/sewage multi-stage treatment, etc., can solve the problems of increased treatment costs, high equipment requirements, and low concentration of acetaldehyde solution. To achieve the effect of overcoming safety problems, reducing processing technology, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

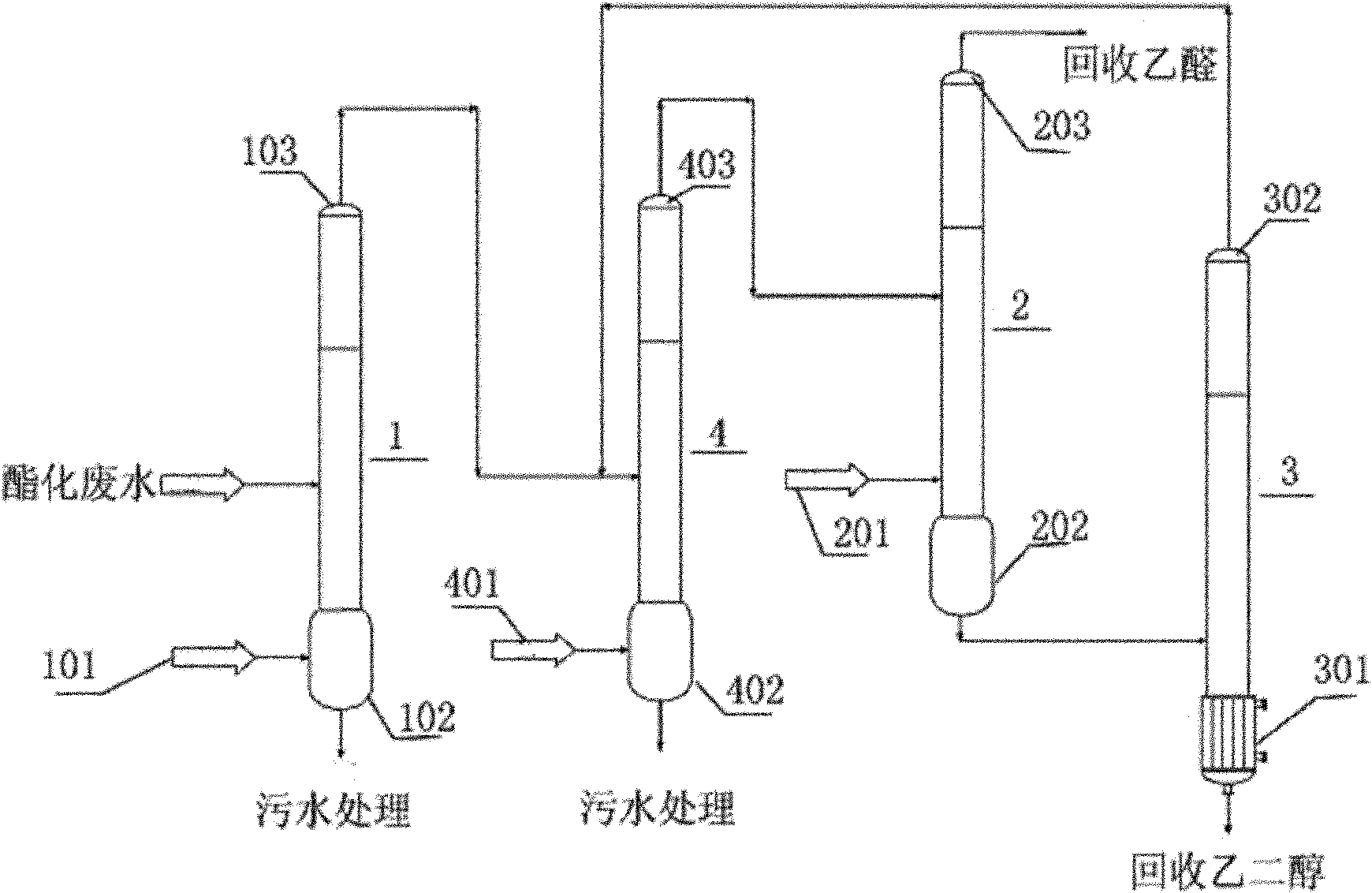

[0038] The treatment process flow without the addition of a wastewater separation tower will be described.

[0039] The process and device of the present invention have been practically applied in well-known enterprises in the polyester industry. The specific process results are as follows:

[0040] According to the actual production situation, the obtained esterification wastewater was processed through the process flow device provided by the present invention to obtain various product components and their contents, as shown in Table 1.

[0041] Table 1 Esterification wastewater and the content of each component of the product

[0042]

[0043] It can be seen from the results after treatment that after being treated by the stripping tower treatment system of the process flow, the acetaldehyde solution with a purity of more than 99.0% was recovered from the acetaldehyde rectification tower system, and the purity was recovered from the ethylene glycol distillation tower. I...

Embodiment 2

[0045] The treatment process flow of adding a wastewater separation tower will be described.

[0046]The process and device of the present invention have been practically applied in well-known enterprises in the polyester industry. The specific process results are as follows:

[0047] According to the actual production situation, the obtained esterification wastewater was processed through the process flow device provided by the present invention to obtain various product components and their contents, as shown in Table 2.

[0048] Table 2 Esterification wastewater and the content of each component of the product

[0049]

[0050] It can be seen from the results after treatment that after being treated by the wastewater separation tower treatment system of the process flow, the acetaldehyde solution with a purity of more than 95.0% was recovered from the acetaldehyde rectification tower system, and the purity was recovered from the ethylene glycol distillation tower. It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com