Preparation method of magnetized silicon dioxide aerogel

A technology of silica and aerogel, applied in chemical instruments and methods, alkali metal oxides/hydroxides, silicon compounds, etc. Low airgel density and other issues, to achieve the effect of low preparation cost, easy large-scale production, and increase light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

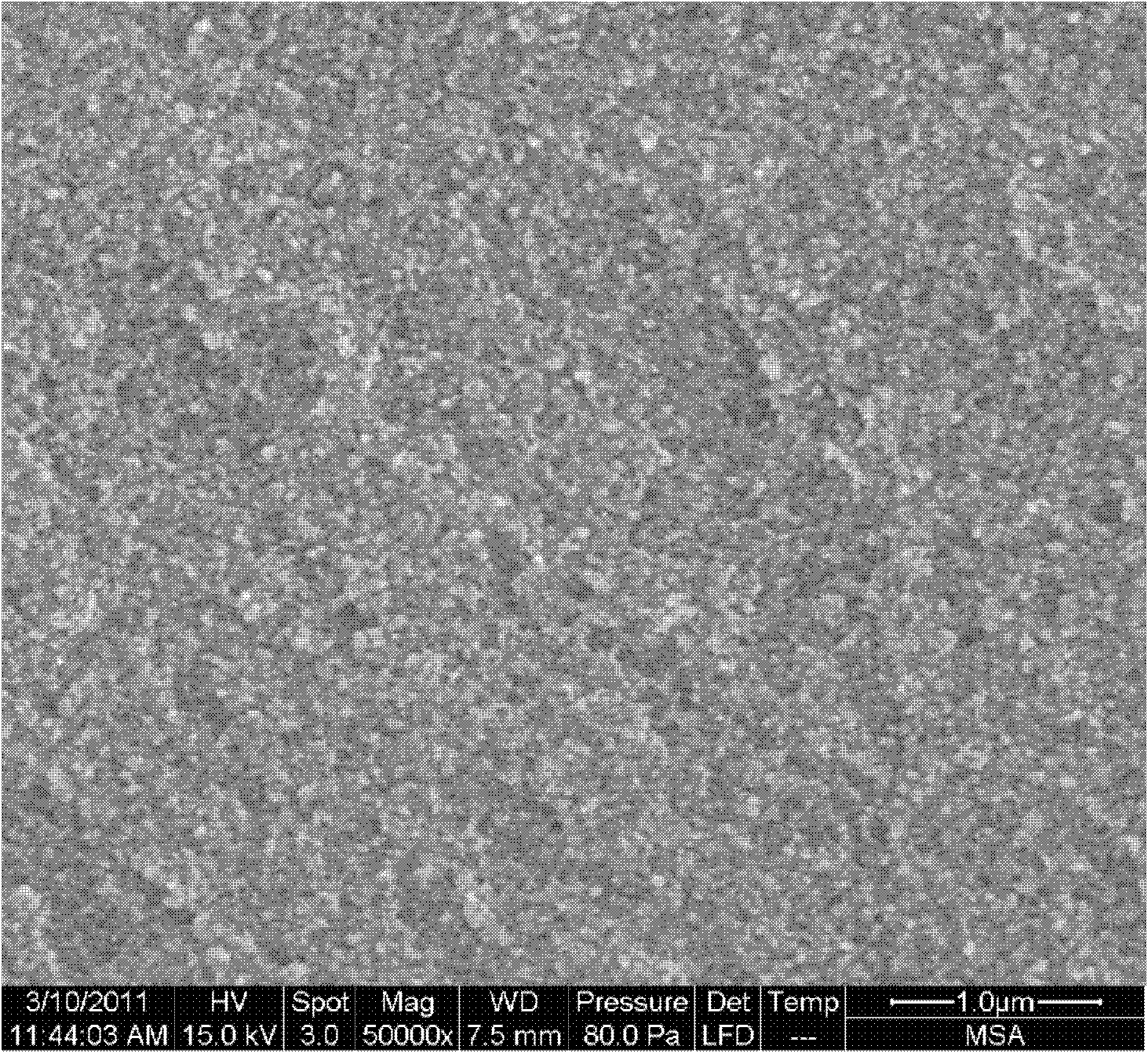

[0033] Embodiment 1: Preparation of magnetized silica airgel

[0034] Prepare 0.1mol / L ferrous chloride solution and prepare 0.001mol / L sodium hydroxide solution. Stir continuously at a constant temperature of 50°C, slowly add the above-prepared sodium hydroxide solution dropwise to the above-prepared ferrous chloride solution to pH = 13, continue stirring and reacting for 2 hours to obtain a nano-scale ferric oxide dispersion. Dilute water glass (Be°=30) with deionized water to 1 time of its original volume, and perform ion exchange with 001×14.5 strongly acidic cation exchange resin to obtain a water sol. At room temperature, add glycerol to the hydrosol as a drying control chemical additive, and then add nano-scale iron ferric oxide dispersion to obtain a mixed solution, and the volume ratio of glycerol to hydrosol is 0.01, and the nano-scale iron ferric oxide The volume ratio of the dispersion liquid to the water sol is 0.01, and the mixed liquid is continuously stirred a...

Embodiment 2

[0035] Embodiment 2: Preparation of magnetized silica airgel

[0036] Prepare 1mol / L ferrous chloride solution and 1mol / L sodium hydroxide solution. Stir continuously at a constant temperature of 25°C, slowly add the above-prepared sodium hydroxide solution dropwise to the above-prepared ferrous chloride solution until pH = 11, and continue stirring for 1 hour to obtain a nano-scale ferric oxide dispersion. Dilute the water glass (Be°=50) with deionized water to 4 times the original volume, and perform ion exchange with D152 weakly acidic cation exchange resin to obtain a hydrosol. At room temperature, add formamide to the hydrosol as a drying control chemical additive, and then add nano-scale ferric oxide dispersion to obtain a mixed solution, and the volume ratio of formamide to hydrosol is 0.5, and the nano-scale ferric oxide dispersion The volume ratio to the hydrosol is 1, and the mixed solution is continuously stirred at a constant temperature of 25°C, and the sodium hy...

Embodiment 3

[0037] Embodiment 3: Preparation of magnetized silica airgel

[0038] Prepare 10mol / L ferrous sulfate solution and 10mol / L ammonia solution. Stir continuously at a constant temperature of 5°C, slowly add the above-prepared ammonia solution dropwise to the above-prepared ferrous sulfate solution to pH = 10, and continue stirring for 1 hour to obtain a nano-scale ferric oxide dispersion. Dilute water glass (Be°=50) with deionized water to 6 times its original volume, and perform ion exchange with 001×7 strong acidic cation exchange resin to obtain a hydrosol. At room temperature, add oxalic acid to the hydrosol as a drying control chemical additive, and then add nano-scale ferric oxide dispersion to obtain a mixed solution, and the volume ratio of oxalic acid to hydrosol is 1, and the nano-scale ferric oxide dispersion and water The volume ratio of the sol is 10, and the mixed solution is continuously stirred at a constant temperature of 5°C, and the ammonia solution prepared a...

PUM

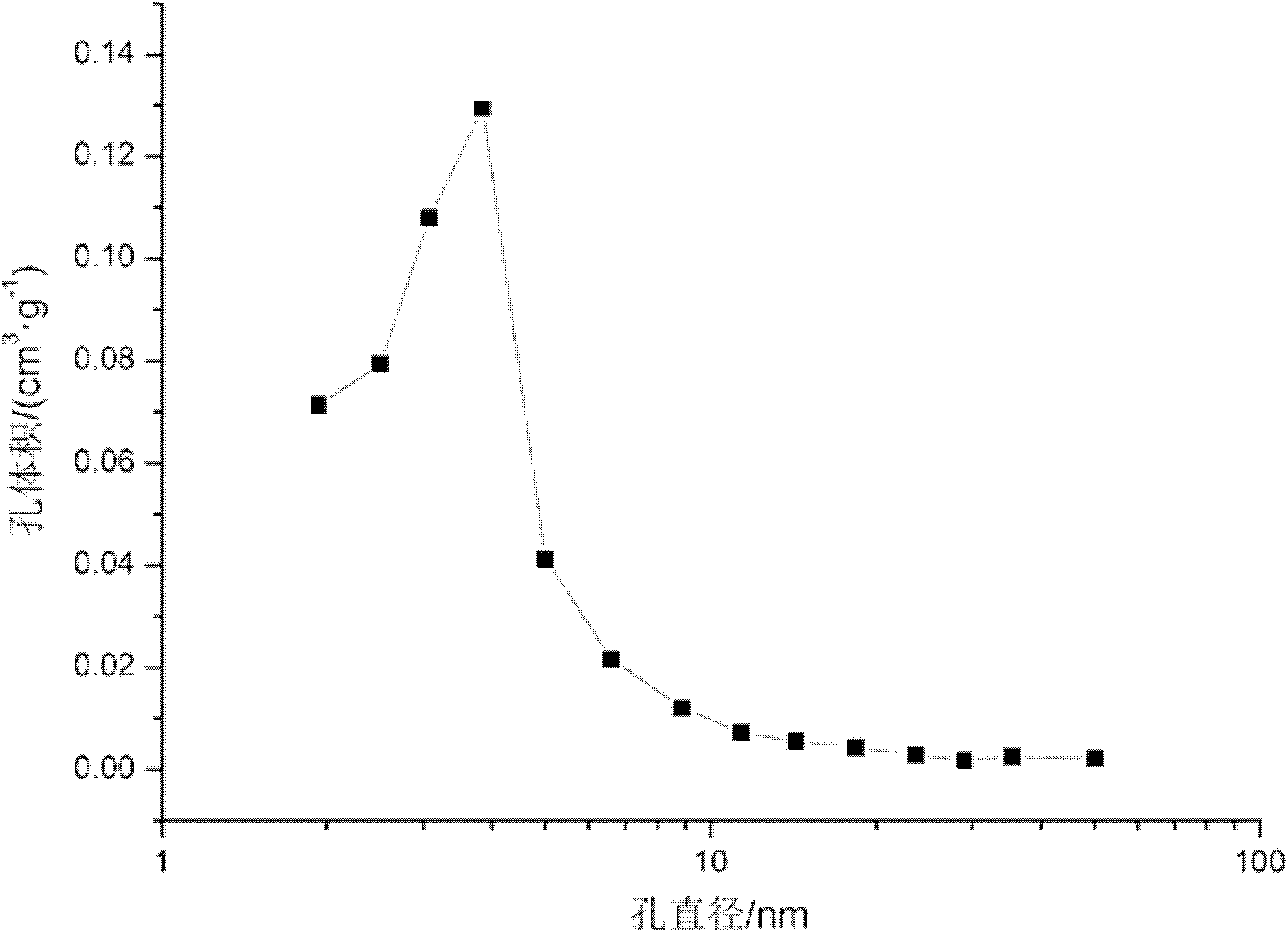

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com