Nano silver antibacterial vacuum cup and processing technology thereof

A nano-silver antibacterial and vacuum cup technology, which is applied in vacuum evaporation plating, metal material coating technology, bactericide, etc., can solve the problems of high silver consumption and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described with reference to the drawings

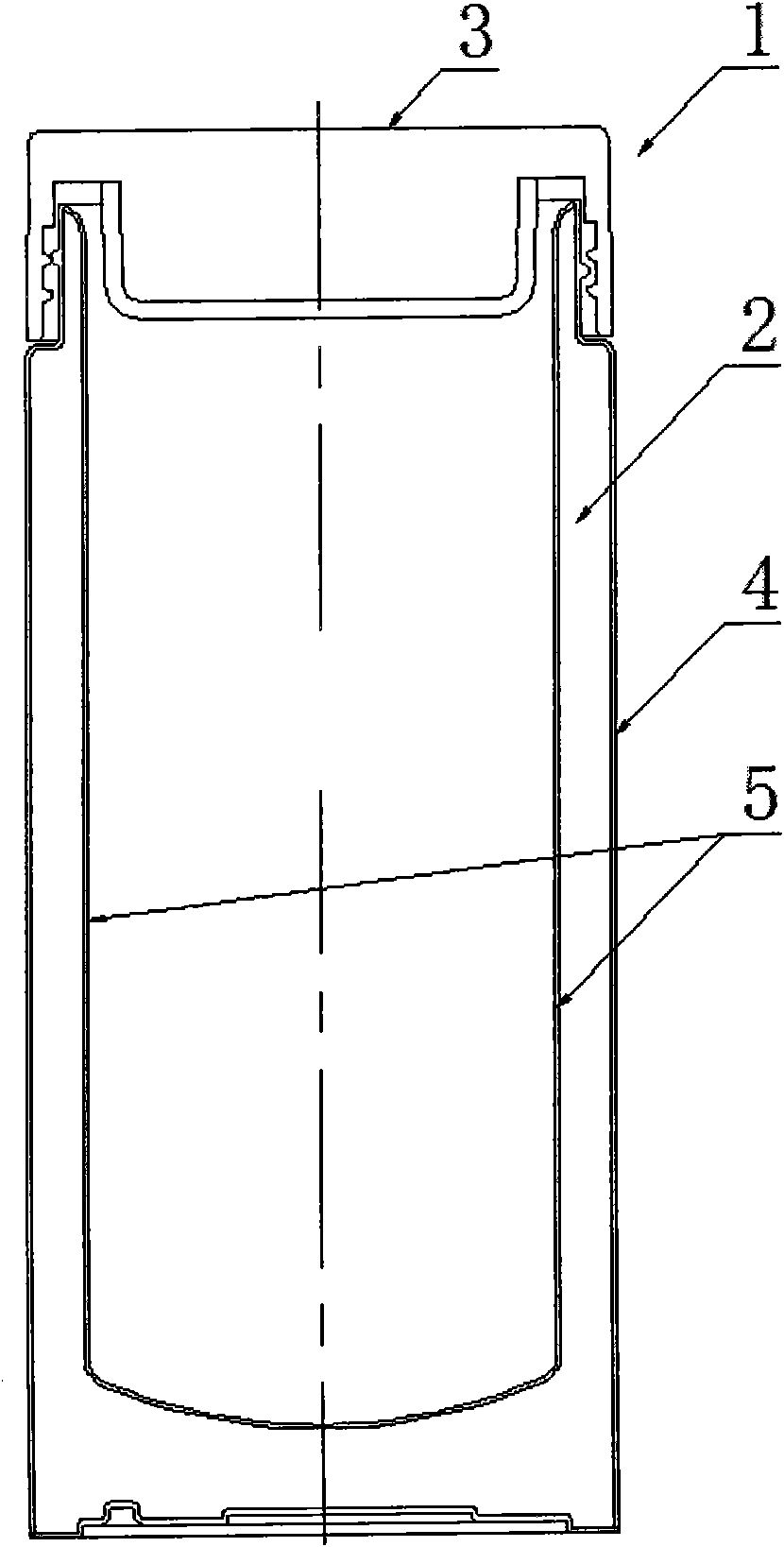

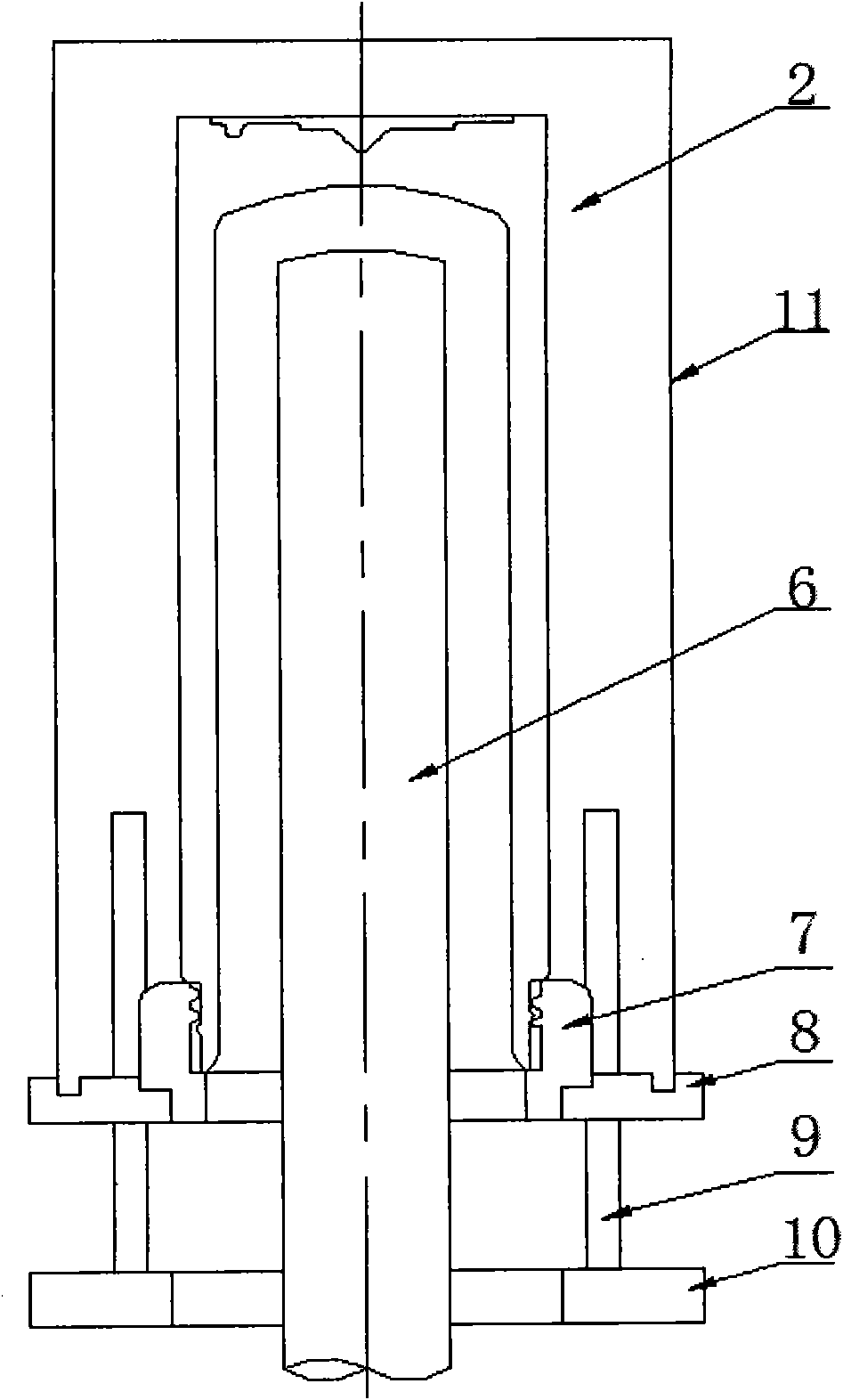

[0017] A nano-silver antibacterial vacuum cup 1, which is composed of an open cup body 2 with a vacuum partition, a cup cover 3 that can be tightly attached to the opening, and a shell 4 supporting the cup body. The composition is: the inner surface of the cup is covered With uniformly distributed and tightly arranged nano silver antibacterial film 5

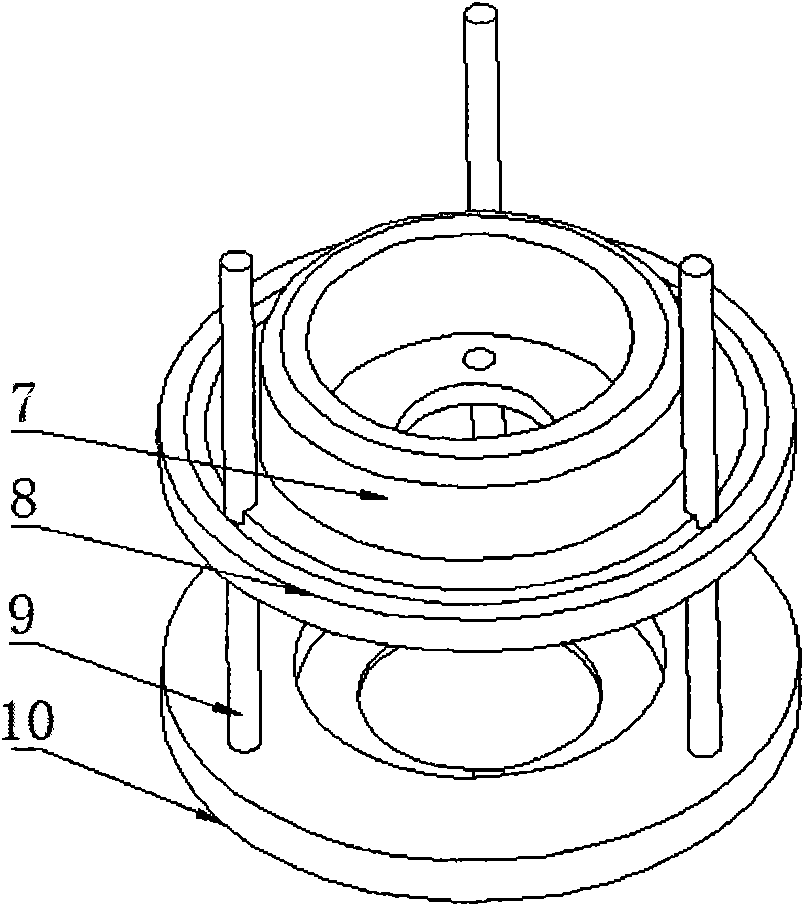

[0018] A manufacturing process of nano-silver antibacterial vacuum cup, which is composed of outer shell, cover, bottom molding, and silver plating of the inner tank; the inner tank is made by the following steps: rough embryo cleaning and drying; inner surface cleaning of the cup , Drying; Electrode cleaning; In the vacuum chamber, the cup holder is moved into the cup with a fixture, also called coating fixture, to adjust the position between the inner surface of the cup and the electrode; the vacuum chamber is sealed, and the vacuum is gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com