Method for preparing grapheme-quantum dot composite film and solar battery structured by using same

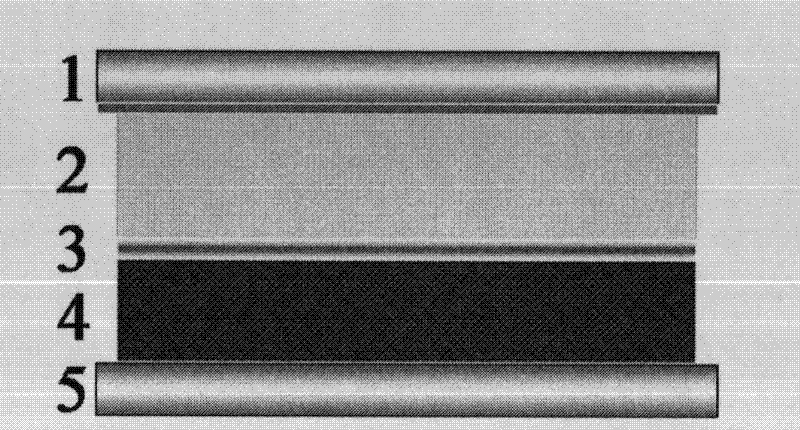

A technology of solar cells and composite thin films, applied in the field of solar cells, can solve problems such as low surface coverage, affect photoelectric conversion efficiency, limit photocurrent density, etc., achieve the effect of reducing probability and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of preparation method of graphene-quantum dot composite film comprises the steps:

[0030] (1) Use 1g of natural graphite powder as raw material, add 0.8g of sodium nitrate, cold concentrated sulfuric acid and 3g of potassium permanganate, mix evenly when it is lower than 20°C, and then heat up to 35°C for 30min. Slowly add deionized water to the above mixed solution for dilution, raise the temperature to 98°C for 15 minutes, then add 10ml of 30% hydrogen peroxide solution; then centrifugally filter the above solution, wash with dilute hydrochloric acid solution to remove metal ions, and then use deionized Washing with water to remove excess acid, and washing with water several times to neutrality, finally obtain an aqueous solution of graphite oxide flakes, which is then subjected to ultrasonic treatment to obtain a yellow-brown uniformly dispersed graphene oxide solution.

[0031] (2) Take the above-mentioned uniformly dispersed graphene oxide sol...

Embodiment 2

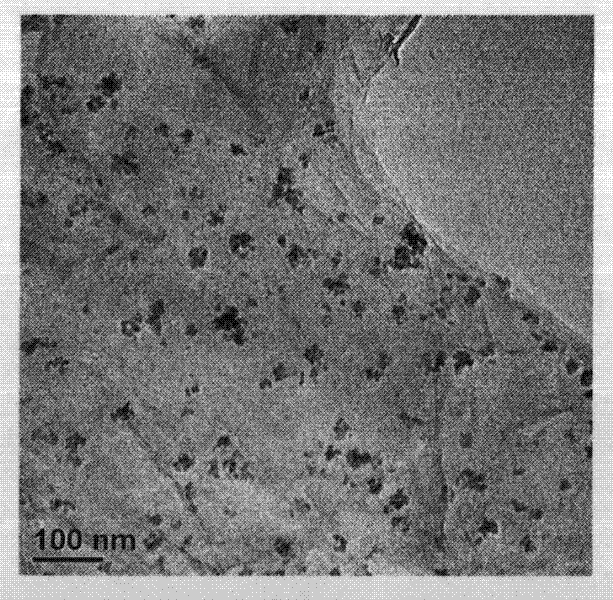

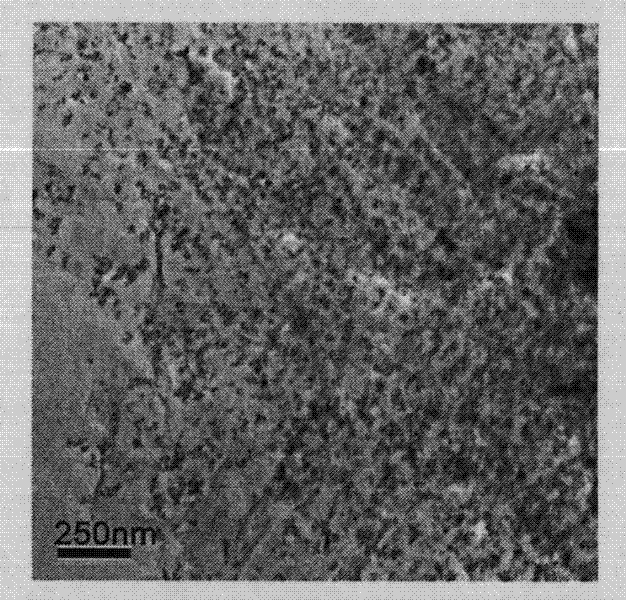

[0036] Example 2: The preparation process and steps in this example are exactly the same as those in Example 1 above. The difference is: the graphene oxide and the reaction solution are mixed in a ratio of 1:1.5. figure 1 It is the transmission electron microscope (TEM) photo figure of this embodiment.

Embodiment 3

[0037] Example 3: The preparation process and steps in this example are exactly the same as those in Example 1 above. The difference is: the graphene oxide and the reaction solution are mixed in a ratio of 1:6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com