Intelligent temperature-control anti-freezing bridge deck

An intelligent, bridge deck technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of reduced concrete strength, high engineering cost, easy cable breakage, etc., to prevent local deformation, prevent road surface slippery, and protect heating wire. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

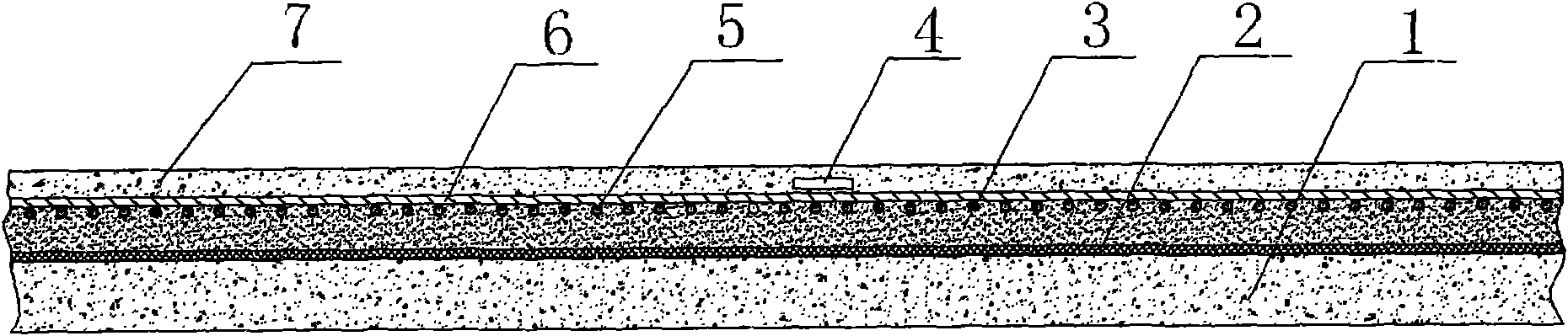

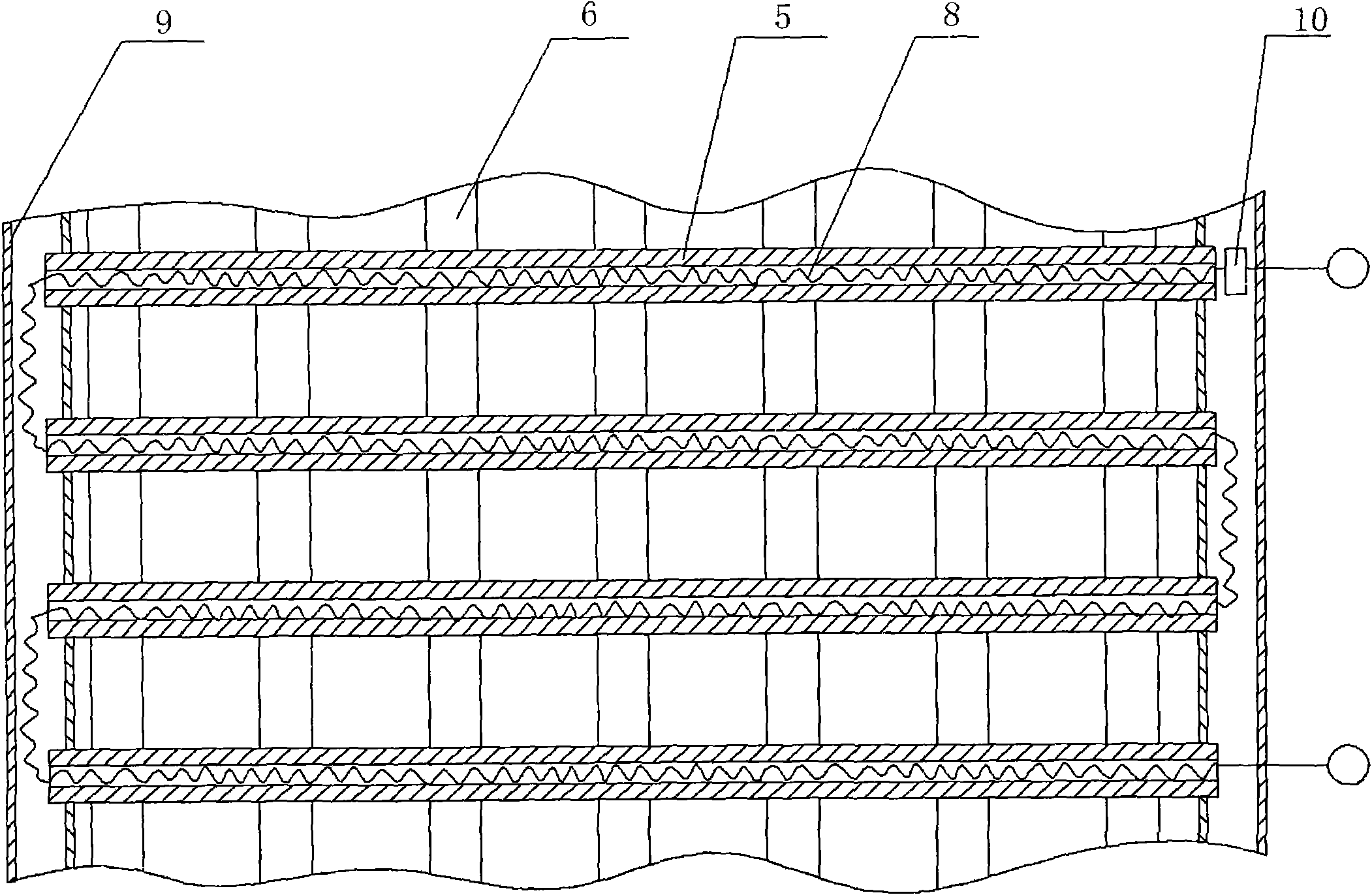

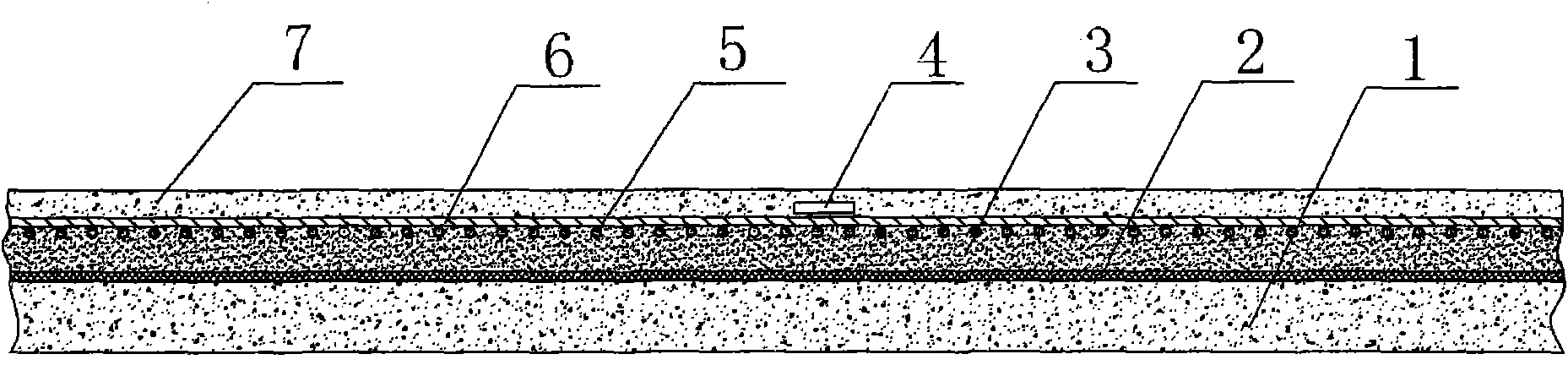

[0009] Such as figure 1 , figure 2 As shown, an intelligent temperature control and antifreeze bridge deck, laying an insulation layer 2 on the bridge deck 1, pouring the lower concrete 3 on the insulation layer 2, laying steel pipes 5 on the lower concrete 3, laying steel bars 6 on the steel pipes 5, pre-embedded the bridge In-plane temperature sensor 4, pouring upper layer concrete 7, electric heating wire 8 is arranged in steel pipe 5, and the two ends of steel pipe 5 are enclosed within steel channel 9, and temperature controller 10 is arranged on electric heating wire 8 connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com