800 MPa grade cold-rolling dual-phase steel and manufacturing method thereof

A manufacturing method and 800mpa technology, applied in metal rolling, manufacturing tools, metal rolling and other directions, can solve the problems of high equipment capability and control level requirements, increase the difficulty of process control, unfavorable industrial production, etc., and achieve easy industrialization. The effect of production, increasing vehicle collision safety, and smelting cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

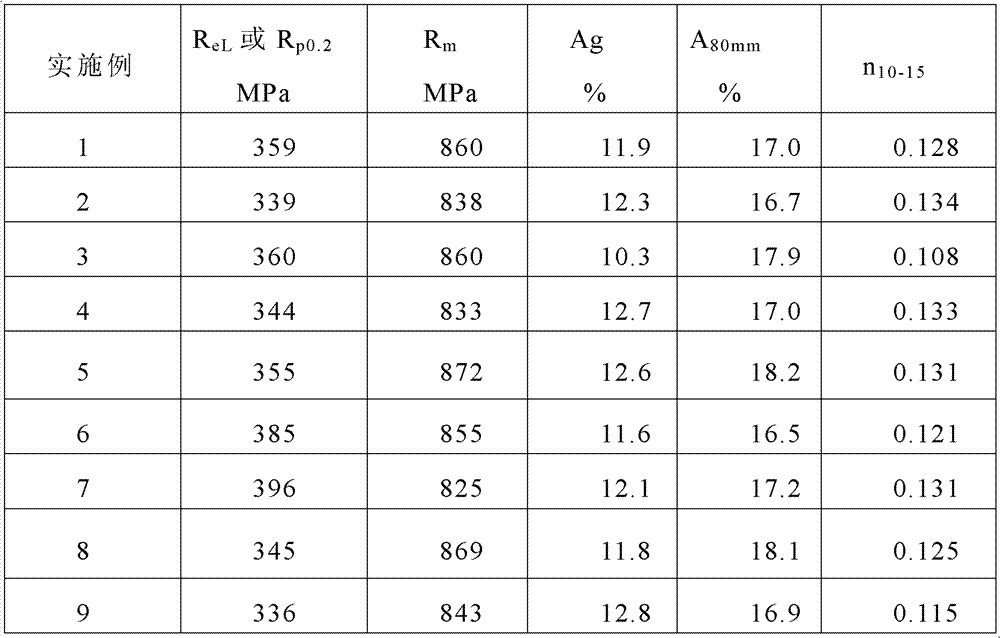

[0028] The 800MPa grade cold-rolled dual-phase steel of the present invention and its manufacturing method are further described in detail below in conjunction with specific embodiments and accompanying drawings:

[0029]Adopt 50kg vacuum induction furnace to smelt in pilot plant, each embodiment measured chemical composition is as shown in Table 1 (surplus is Fe and unavoidable impurity). The steel billet is heated with the furnace to 1150-1250°C and held for 1.5-3 hours, and then rolled on a conventional hot rolling mill. Controlled at 560-600°C, the hot-rolled sheet is pickled and then cold-rolled on a conventional cold-rolling mill. The hot-dip galvanizing simulation testing machine of the German IWATANI company is annealed. After the sample is kept at 760-860°C for 60s-300s, it is slowly cooled to 600-700°C and then rapidly cooled to 250-350°C for 5-10min overaging. Cool to room temperature after processing.

[0030] Table 1:

[0031] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com