Ta doped CeO2 depletion layer film and preparation method thereof

A transition layer and film technology, applied in the field of Ta-doped CeO2 transition layer film and its preparation, can solve the problems of hindering element diffusion and reaction, YBCO quality decline, film surface cracking, etc. textured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Dissolve cerium acetylacetonate and tantalum chloride in 4ml of n-propionic acid and 1ml of methanol, heat and stir until Completely dissolve to obtain the precursor solution;

[0027] 2) Apply the precursor solution to the cleaned NiW substrate by spin coating at a speed of 2000rpm for 30s to obtain a precursor film;

[0028] 3) in N 2 -H 2 (H 2 -4%) under gas protection atmosphere, heated to 950 ° C, took out after 5 minutes of heat preservation, and obtained a Ta with a thickness of 30 nm and a cubic texture. 0.1 Ce 0.9 o 2 Single transition layer film.

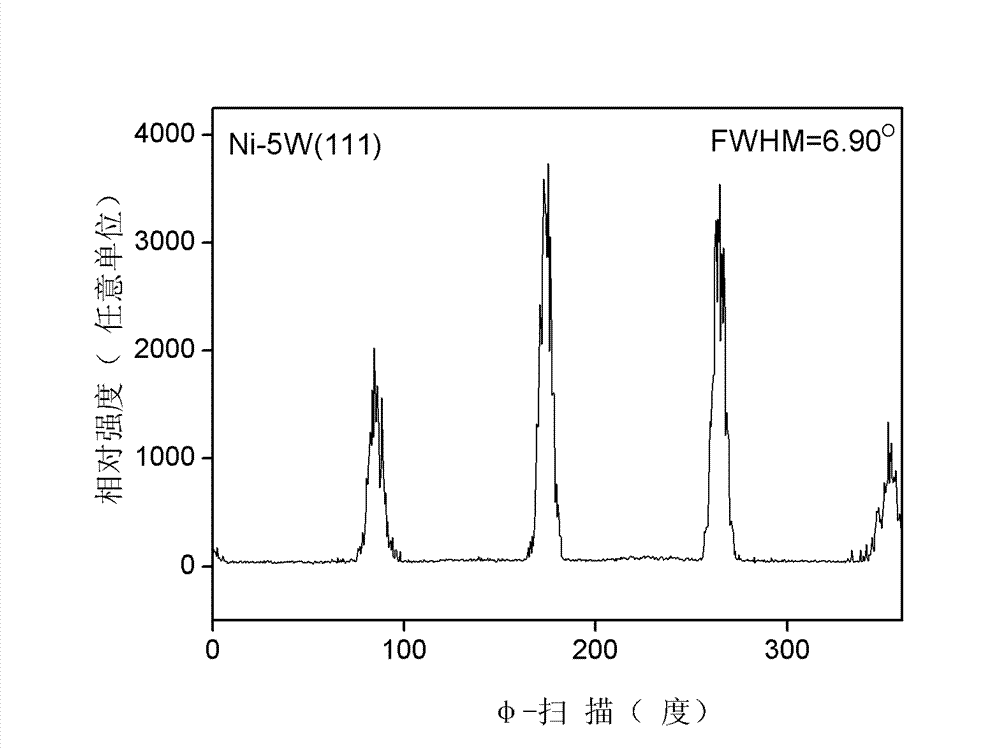

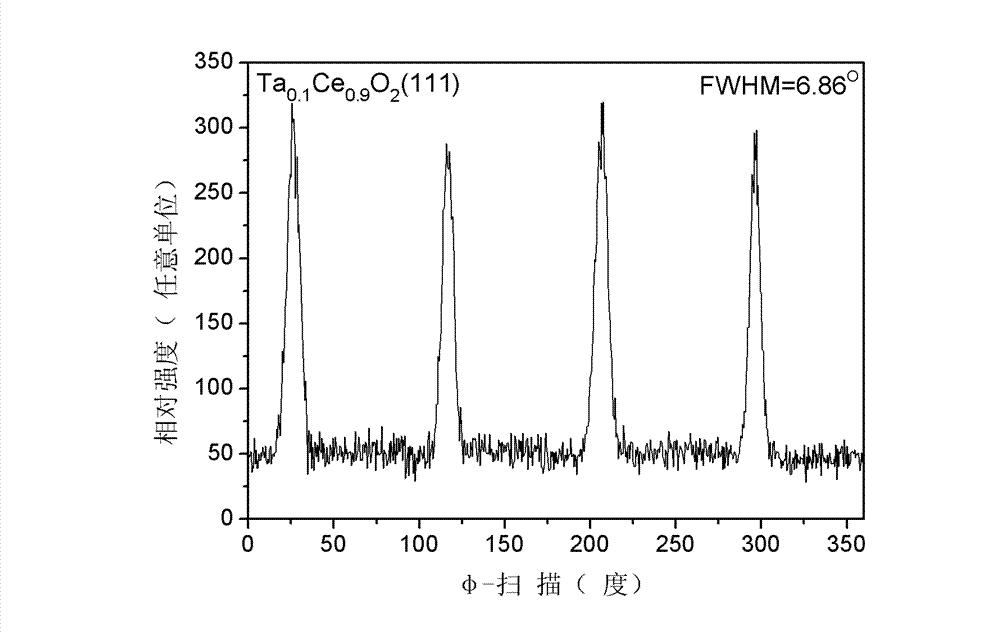

[0029] figure 1 It is the pole figure of the NiW metal substrate (111) used, showing that its in-plane height and width are 6.90; figure 2 For Ta 0.1 Ce 0.9 o 2 The (111) plane pole figure of the transition layer film has a FWHM (width at half maximum) of 6.86, which is lower than the in-plane FWHM value of the NiW baseband, proving that Ta 0.1 Ce 0.9 o 2 The transition layer film can not only impr...

Embodiment 2

[0031] 1) Dissolve cerium acetylacetonate and tantalum ethylate in 4ml of n-propionic acid at a molar ratio of cerium ions to tantalum ions of 4:1, with a total concentration of cerium ions and tantalum ions of 0.8mol / L, and heat and stir until completely dissolved to obtain Precursor;

[0032] 2) Apply the precursor solution to the cleaned NiW substrate by spin coating at a rotation speed of 5000rpm for 40s to obtain a precursor film;

[0033] 3) in N 2 -H 2 (H 2 -4%) under gas protection atmosphere, heat to 1200°C, take it out after 30 minutes of heat preservation,

[0034] 4) Obtain Ce with a thickness of 120nm and a cubic texture 0.67 Ta 0.33 o 2 Single transition layer film.

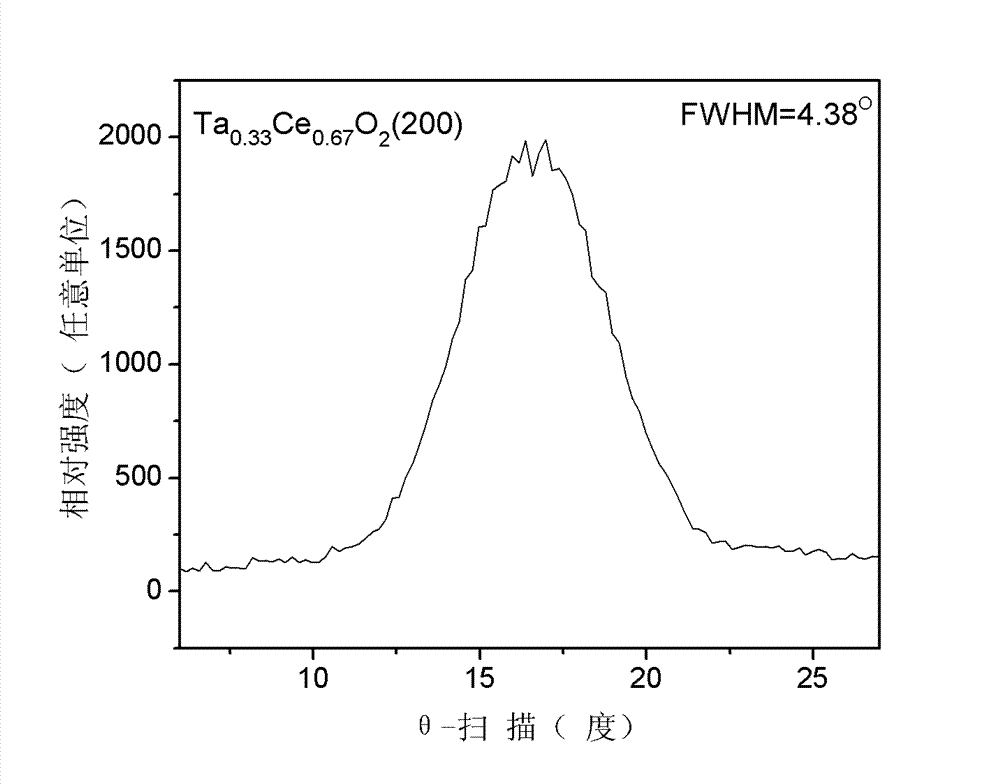

[0035] image 3 For Ta 0.2 Ce 0.8 o 2 The transition layer film has a rocking-curve of the out-of-plane half maximum value.

Embodiment 3

[0037] 1) Dissolve cerium acetylacetonate and tantalum ethylate in 4ml of n-propionic acid at a molar ratio of cerium ions to tantalum ions of 3:1, with a total concentration of cerium ions and tantalum ions of 0.4mol / L, and heat and stir until completely dissolved to obtain Precursor;

[0038] 2) Apply the precursor solution to the cleaned NiW base tape by spin coating, the rotation speed is 3000rpm, and the time is 60s to obtain the precursor film;

[0039] 3) in N 2 -H 2 (H 2 -4%) under gas protection atmosphere, heated to 1100°C, took it out after 60 minutes of heat preservation, and obtained a Ta with a thickness of 60nm and a cubic texture. 0.25 Ce 0.75 o 2 Single transition layer film.

[0040] Figure 4 For Ta 0.25 Ce 0.75 o 2 Depth-of-element analysis curve (AES) of a monolayer transition layer film. The sputtering speed is 10nm / min, and it can be obtained from the curve that the thickness of the single-layer film is 60nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com