Composite conducting strip

A composite conductive and sheet technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of inconvenient selection and manufacture, easy powder falling off, unbalanced conductivity, etc. Good performance and high composite strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

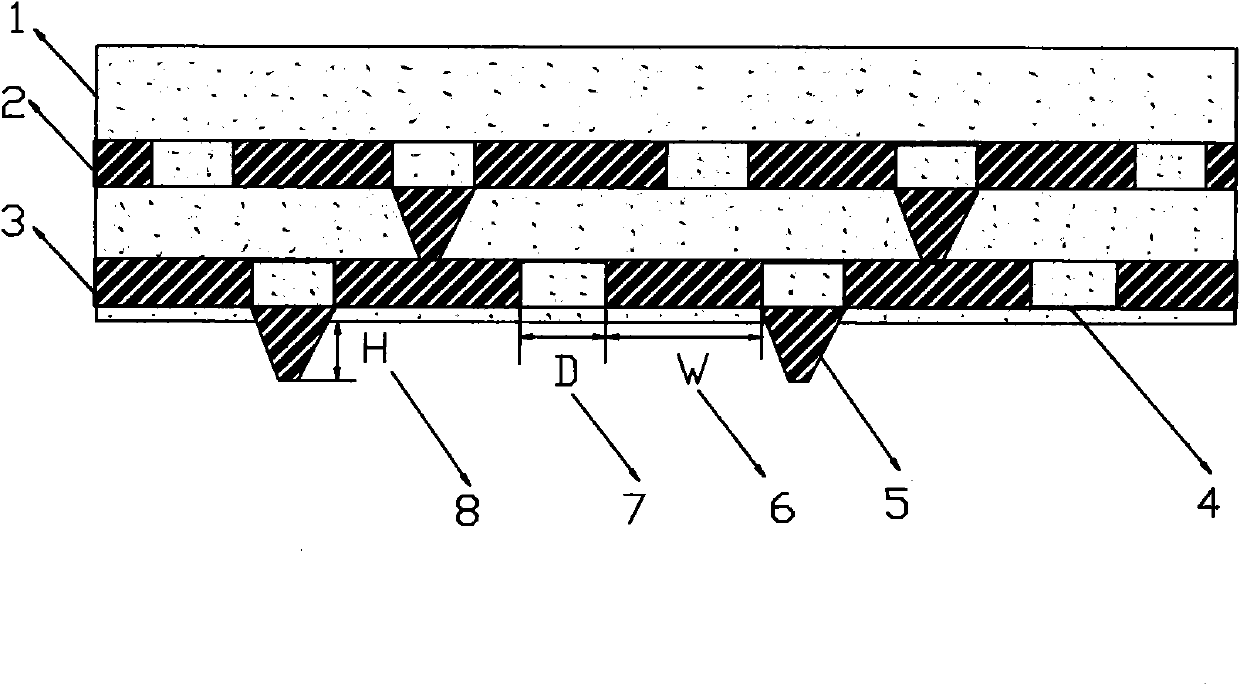

[0017] Select the silicone rubber raw material of the polymer matrix 1, the crosslinking agent of the silicone rubber, and one or several additives in the flame retardant, anti-aging agent, toughening agent, antioxidant, and water-repellent agent, and use nickel foil as the lower layer metal foil3. The thickness of the nickel foil is 10 μm. The nickel foil contains a plurality of protruding contacts 5 with a distance of 0.2 mm and a height H8 of 100 μm. The nickel foil also contains holes with a diameter D7 of 0.1 mm. For a plurality of holes 4 with a hole spacing W6 of ˜2 mm and a hole spacing W6 of 0.2 mm˜2.5 mm, the diameter D7 of some holes may be different, and the size of the hole spacing W6 of some holes may be different. Combine the raw materials of silicone rubber, crosslinking agent, various additives and nickel foil on a suitable machine and mold, and the raw materials of silicone rubber, crosslinking agent and additives are cured into the polymer matrix of silicone...

Embodiment 2

[0019] Select the raw materials of the rubber and plastic materials for the polymer matrix 1, the crosslinking agent for the rubber and plastic materials, and one or several additives among flame retardants, anti-aging agents, toughening agents, antioxidants, and water-repellent agents. The braided mesh of copper wires is used as the upper layer metal foil 2 and the lower layer metal foil 3 . The surface of the braided mesh of copper wire is uneven, the thickness of the braided mesh of copper wire is 1 mm, and the braided mesh of copper wire contains a plurality of protruding contacts with a distance of 2 mm and a height H8 of 5 mm. Point 5 includes a plurality of holes 4 with a hole diameter D7 ranging from 0.1mm to 2mm and a hole spacing W6 ranging from 0.2mm to 2.5mm. The size of the hole diameter D7 can be different, and the size of the hole spacing W6 can be different. Combine the raw materials of rubber and plastic materials, cross-linking agents, auxiliary agents and tw...

Embodiment 3

[0023] Choose one or several kinds of thermoplastic raw materials for manufacturing polymer matrix 1 and thermoplastic flame retardants, anti-aging agents, toughening agents, antioxidants, and water-repellent agents, and use gold-plated stainless steel foil as the lower layer metal foil3. The thickness of the gold-plated stainless steel foil is 0.5 mm. The gold-plated stainless steel foil contains a plurality of protruding contacts 5 with a distance of 2 mm and a height H8 of 0.8 mm. It also contains a hole with an aperture D7 of For a plurality of holes 4 of 0.1 mm to 2 mm and a hole spacing W6 of 0.2 mm to 2.5 mm, the size of the hole diameter D7 can be different, and the size of the hole spacing W6 can be different. The thermoplastic raw material and the gold-plated stainless steel foil are combined on a suitable machine and mold, the thermoplastic raw material is solidified into a thermoplastic polymer matrix 1, and the upper metal foil 2 of the gold-plated stainless steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com