Low-density water bonding well control fluid

A low-density, water pressure technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as corrosion, clogging of formations, water lock damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

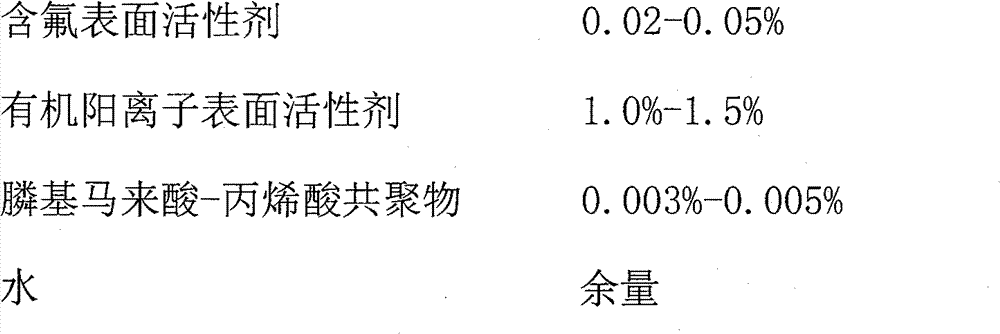

[0024] In 100 kg of water, add 0.02 kg of fluorine-containing surfactant, 1.0 kg of organic cationic surfactant, 0.003 kg of phosphino-maleic acid-acrylic acid copolymer (dissolved in water), and then add 0.5 kg of bound water to polymerize Stir it well and let it sit for 30 minutes to obtain a well-prepared bound hydraulic well fluid. The actual configuration is scaled up according to this ratio.

[0025] Performance of workover fluid: Density: 1.01g / cm 3 , surface tension: 22mN / m, anti-swelling rate: 81.2%, water loss in 30 minutes under 0.7Mpa pressure is less than 9.5% of the kill fluid; stable time at room temperature ≥ 30 days, stable time at 130 ° C ≥ 3 days. Field application was carried out in basin 5 wells.

Embodiment 2

[0027] In 100 kg of water, add 0.05 kg of fluorine-containing surfactant, 1.5 kg of organic cationic surfactant, 0.005 kg of phosphino-maleic acid-acrylic acid copolymer (dissolved in water), and then add 0.666 kg of bound water to polymerize Stir it well and let it sit for 30 minutes to obtain a well-prepared bound hydraulic well fluid. The actual configuration is scaled up according to this ratio.

[0028] Performance of workover fluid: Density: 1.02g / cm 3 , surface tension: 19mN / m, anti-swelling rate: 85.6%, water loss in 30 minutes under 0.7Mpa pressure is less than 6.1% of the kill fluid; stable time at room temperature ≥ 30 days, stable time at 130 ° C ≥ 3 days. Field application in Mazhuang Gas Reservoir Platform 20 Well.

Embodiment 3

[0030] In 100 kg of water, add 0.03 kg of fluorine-containing surfactant, 1.5 kg of organic cationic surfactant, 0.004 kg of phosphino-maleic acid-acrylic acid copolymer (dissolved in water), and then add 0.6 kg of bound water to polymerize Stir it well and let it sit for 30 minutes to obtain a well-prepared bound hydraulic well fluid. The actual configuration is scaled up according to this ratio.

[0031] Performance of workover fluid: Density: 1.02g / cm 3 , surface tension: 21mN / m, anti-swelling rate: 85.1%, water loss in 30 minutes under 0.7Mpa pressure is less than 7.9% of the kill fluid; stable time at room temperature ≥ 30 days, stable time at 130 ℃ ≥ 3 days. Field application in 581 well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com