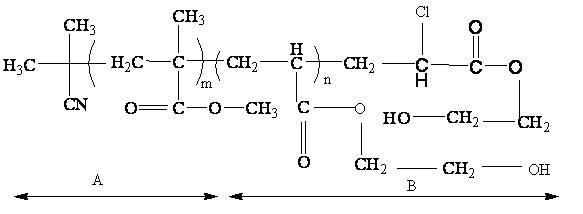

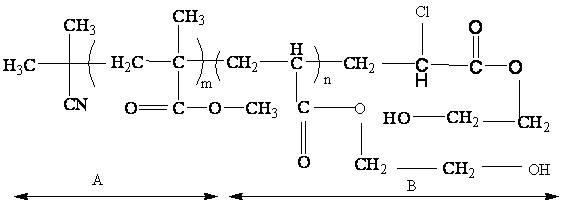

Block copolymer/nano-SiO2 composite material and preparation method thereof

A technology of block copolymer and composite material, which is applied in the field of block copolymer/nano-SiO2 composite material and its preparation, can solve the problems of poor thermal stability and insufficient mechanical properties, and achieve the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Nano-SiO 2 Add the modifying agent γ-methacryloxypropyltrimethylsilane into the solvent toluene, and react at 80°C for 5 hours while stirring. Stand still, suck off the supernatant, vacuum dry at 35°C for 12 hours, and then dry at 120°C for 2 hours to obtain modified nano-SiO 2 . Among them, nano-SiO 2 : The mass ratio of γ-methacryloxypropyltrimethylsilane is 1:0.1, nano-SiO in toluene 2 The concentration is 0.2 g / ml.

[0023] (2) Using methyl methacrylate as a monomer, azobisisobutyronitrile as an initiator, ferric chloride / triphenylphosphine as a catalyst / ligand, and xylene as a solvent, continuously blowing nitrogen for 0.5 hours, in React at 70°C for 4 hours, cool, add tetrahydrofuran until the polymer is completely dissolved, pass through a neutral alumina chromatography column, add methanol to the filtrate until complete precipitation, wash the precipitate with deionized water 3 times, and store at 80°C Vacuum-dried to constant weight to obtain polymethy...

Embodiment 2

[0027] (1) The method is the same as step (1) in Example 1. Among them, the reaction temperature is 100°C, the reaction time is 5 hours, and the nano-SiO 2 : The mass ratio of γ-methacryloxypropyltrimethylsilane is 1:0.2, nano-SiO in toluene 2 The concentration is 0.4 g / ml.

[0028] (2) The method is the same as step (2) of Example 1. The reaction temperature is 90°C, the reaction time is 4 hours, the molar ratio of initiator:catalyst:ligand:monomer is 1:1:3:150, and the concentration of monomer methyl methacrylate in xylene is 0.8 g / ml.

[0029] (3) The method is the same as step (3) of Example 1. The reaction temperature is 80°C, the reaction time is 5 hours, the molar ratio of macromolecular initiator:catalyst:ligand:monomer is 1:1:3:380, and the concentration of monomer-2-hydroxyethyl acrylate is 0.3g / ml .

[0030] (4) The method is the same as step (4) of Example 1. Among them, the reaction temperature is 70°C, the reaction time is 6 hours, and the modified nano-S...

Embodiment 3

[0032] (1) The method is the same as step (1) in Example 1. Among them, the reaction temperature is 90°C, the reaction time is 5 hours, and nano-SiO 2 : The mass ratio of γ-methacryloxypropyltrimethylsilane is 1:0.3, nano-SiO in toluene 2 The concentration is 0.5g / ml.

[0033] (2) The method is the same as step (2) of Example 1. The reaction temperature is 80°C, the reaction time is 5 hours, the molar ratio of initiator:catalyst:ligand:monomer is 1:1:3:250, and the concentration of monomer methyl methacrylate in xylene is 1.0g / ml.

[0034] (3) The method is the same as step (3) of Example 1. The reaction temperature is 90°C, the reaction time is 4 hours, the molar ratio of macromolecular initiator:catalyst:ligand:monomer is 1:1:3:320, and the concentration of monomer-2-hydroxyethyl acrylate is 0.25g / ml .

[0035] (4) The method is the same as step (4) of Example 1. Among them, the reaction temperature is 70°C, the reaction time is 6 hours, and the modified nano-SiO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com