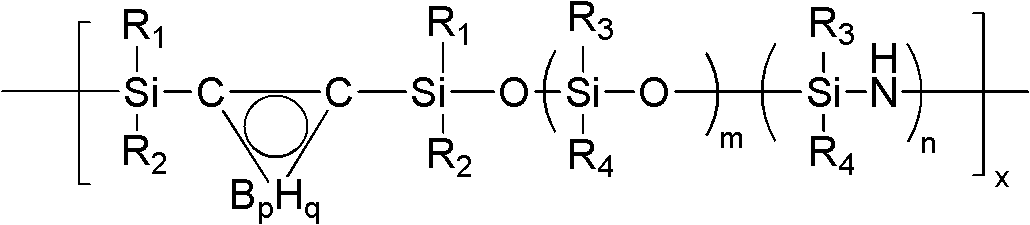

Poly(carborane-siloxane/silazane) polymer and preparation method thereof

A carborane and polymer technology, applied in the field of high-temperature-resistant polymers and their preparation, can solve the problems of difficult growth of molecular weight, excessive silicon-nitrogen bonds, and difficult regulation of molecular structure, etc., and achieve the effect of great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

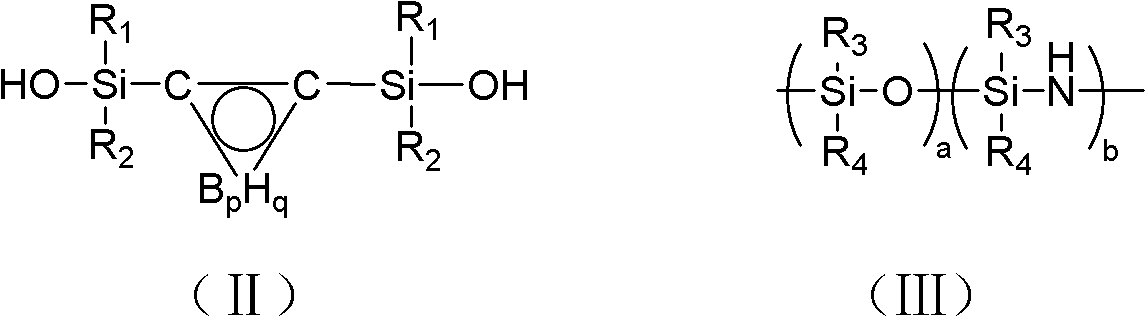

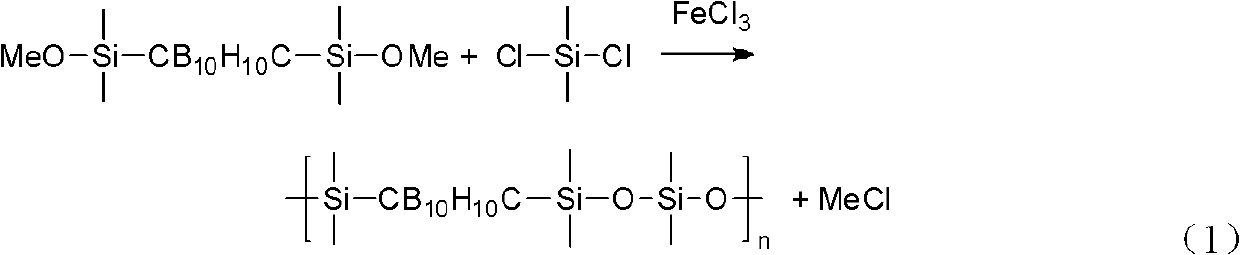

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, the preparation of poly(carborane-siloxane / silazane) polymer

[0045] Under an inert atmosphere, put 2.44g of bis(hydroxydimethylsilyl)-m-carborane and 0.61g of hexamethylcyclotrisilazane in a reaction flask, and add 5mL of toluene and 0.5g of anhydrous acetic acid (where , the amount of acetic acid is two (hydroxydimethylsilyl)-m-carborane and hexamethylcyclotrisilazane (structure shown in formula (III), wherein, a is 0, b is 3, R 3 and R 4 16.4% of the total mass of methyl group), stirred and reacted at 90° C. for 24 hours. After the reaction, the solution obtained was washed with methanol to remove small molecules to obtain a white waxy solid polymer. Its number average molecular weight is 2.8×10 4 , with a weight average molecular weight of 4.2×10 4 , Elemental analysis: C 28.04%, H 8.23%, N 0.62%. by 29 Si NMR analysis shows that its structure is shown in formula (IV), wherein the degree of polymerization x is 118.

[0046]

Embodiment 2

[0047] Embodiment 2, the preparation of poly(carborane-siloxane / silazane) polymer

[0048] Under an inert atmosphere, 7.25g of bis(hydroxydiphenylsilyl)-m-carborane and 0.98g of hexamethylcyclotrisilazane were added to the reaction flask, and 0.5g of acetic anhydride was added (wherein, acetic anhydride The consumption is bis(hydroxyl diphenylsilyl)-m-carborane and hexamethylcyclotrisilazane (structure shown in formula (III), wherein, a is 0, b is 3, R 3 and R 4 6.1% of the total mass of the methyl group), reacted at 110° C. for 24 hours under solvent-free conditions, raised the temperature to 150° C. and continued to stir and reacted for 12 hours. After the reaction, a viscous polymer was obtained. Wash away the small molecules with methanol, and measure the number average molecular weight to be 4.6×10 4 , with a weight average molecular weight of 7.0×10 4 ,by 29 Si NMR analysis shows that its structure is shown in formula (V), wherein the degree of polymerization x is 10...

Embodiment 3

[0050] Embodiment 3, the preparation of poly(carborane-siloxane / silazane) polymer

[0051] Under an inert atmosphere, mix 2.00 g of bis(hydroxydimethylsilyl)-m-carborane with 0.58 g of 1,3,5-trimethyl-1,3,5-trivinyl-cyclotrisilazide Add 0.05g of ammonium chloride into the reaction flask, and add 0.05g of ammonium chloride as a catalyst (wherein, the amount of ammonium chloride is two (hydroxyl diphenylsilyl)-m-carborane and 1,3,5-trimethyl- 1,3,5-trivinyl-cyclotrisilazane (structure shown in formula (III), wherein, a is 0, b is 3, R 3 Methyl, R 4 1.9% of the total mass of vinyl), add 10mL xylene as a solvent, and stir and react at 110° C. for 24 hours. After the reaction is finished, wash off small molecular substances with methanol to obtain a white waxy polymer. The number average molecular weight was determined to be 1.4×10 5 , with a weight average molecular weight of 1.6×10 5 ,by 29 Si NMR analysis shows that its structure is shown in formula (VI), wherein the degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com