Adsorbent for adsorbing and separating m-xylene and preparation method of same

A technology for m-xylene and adsorption separation, applied in the direction of adsorption purification/separation, chemical instruments and methods, and other chemical processes, which can solve the problems of low adsorption capacity and application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of adsorbent of the present invention comprises:

[0024] (1) NaY zeolite and kaolin group minerals are mixed and agglomerated into particles, then dried and roasted;

[0025] (2) Treat the calcined particles with sodium hydroxide solution or a mixed solution of sodium hydroxide and sodium silicate at 90-100° C., so that the kaolin group minerals therein are in-situ crystallized into Y zeolite;

[0026] (3) Carry out cation exchange with strontium soluble salt solution, then wash, dry and activate.

[0027] In the above preparation method, step (1) is the coalescence molding of NaY zeolite and kaolin group minerals, and the mass ratio of zeolite and kaolin group minerals used in molding is 85-95:5-15. The coalescing molding can be carried out according to various techniques well known to those skilled in the art, such as extruding, pressing or rolling into balls. From the consideration of the hydrodynamics of the adsorbent filling and use process...

example 1

[0049] Prepare the adsorbent of the present invention and carry out the adsorption performance test.

[0050] (1) Rolling ball molding: 88 kg (mass on dry basis, the same below, produced by Sinopec Catalyst Changling Branch) with a silica / alumina molar ratio of 5.32, an average grain size of 0.8 microns, and a toluene adsorption capacity of 237 mg / The NaY type zeolite of gram is mixed with 9.8 kilograms of kaolin (containing 90 mass % of kaolinite, produced in Linfen, Shanxi Province) and 3.4 kilograms of turnip powder to form a mixed powder, put into a turntable and spray an appropriate amount of water while rolling, so that The solid mixed powder is agglomerated into small balls, and the amount of water sprayed into when rolling the ball is 25% by mass of the solid mixed powder. The pellets with a diameter of 0.35 to 0.80 mm were sieved, dried at 80°C for 10 hours, and roasted at 540°C for 4 hours in an air stream. The toluene adsorption capacity was determined to be 211 mg...

example 2

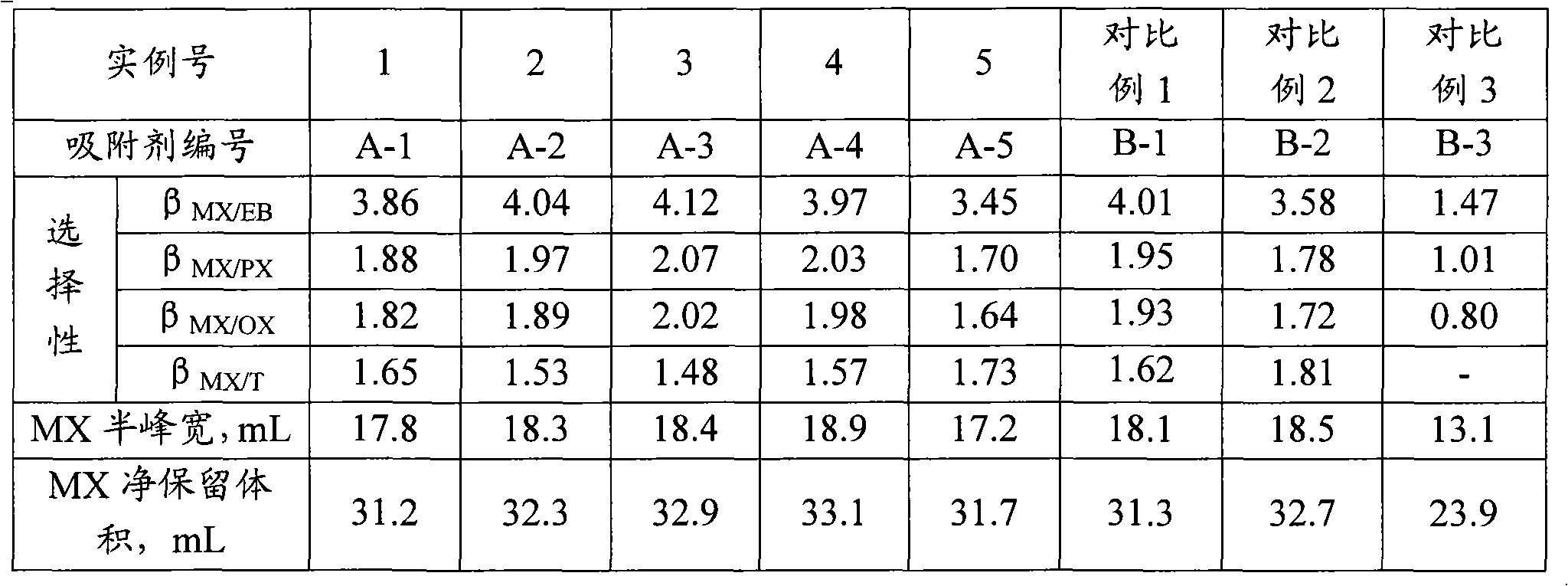

[0055] The adsorbent was prepared according to the method of Example 1, except that the concentration of the strontium chloride aqueous solution used in (3) step ion exchange was 0.04moL / L. X-ray fluorescence spectrometry determines that after ion exchange, the adsorbent contains 1.79% by mass of strontium oxide and 11.12% by mass of sodium oxide, and the molar ratio of sodium oxide to strontium oxide is 10.4:1. Drying in a nitrogen stream at 230°C for 2 hours obtains adsorbent A -2, the ignition loss after roasting at 600°C for 2 hours is 3.1% by mass. The selectivity of the adsorbent, MX half-peak width and net retention volume measured by the pulse test are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com