Production method of stabilized solid wood composite floor with buffer layer

A solid wood composite flooring and production method technology, which is applied in the direction of plywood presses, veneer presses, wood processing appliances, etc., can solve the problems of adding a buffer layer and increasing the curing time of blanks, etc., so as to increase the bonding area of the surface layer, Effects of improving stability and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

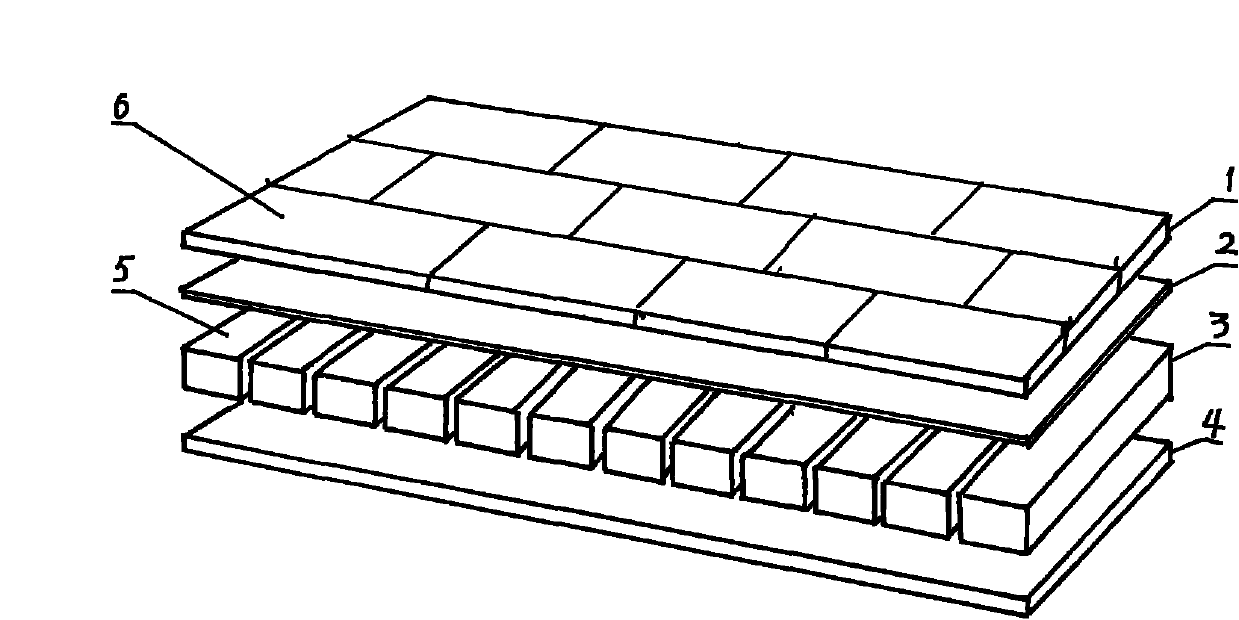

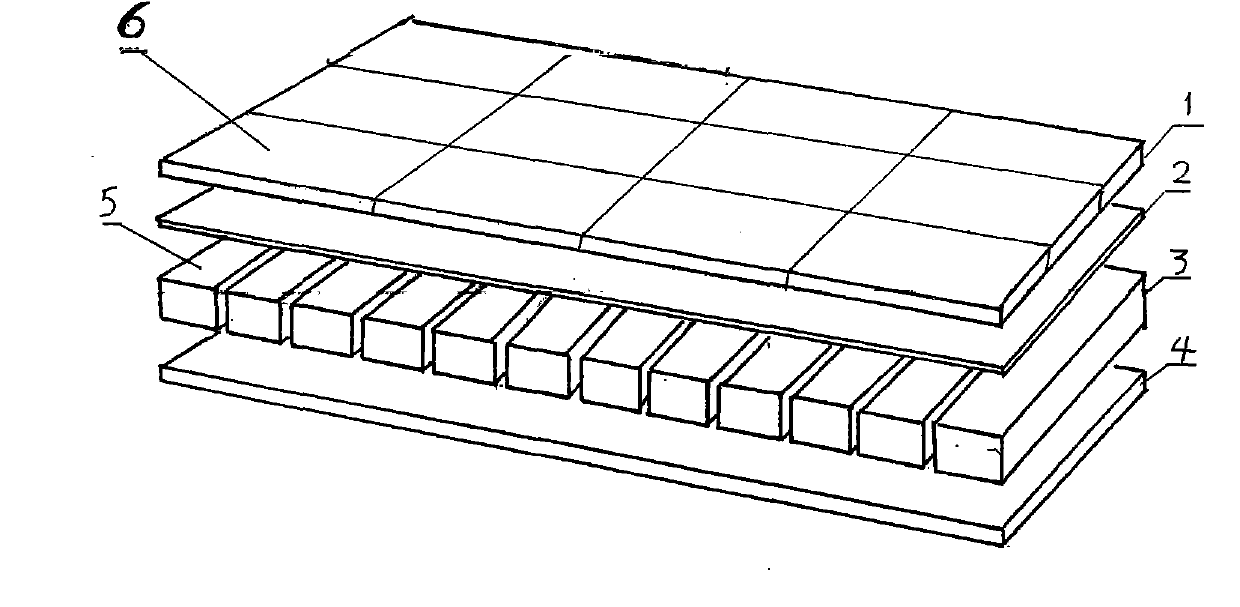

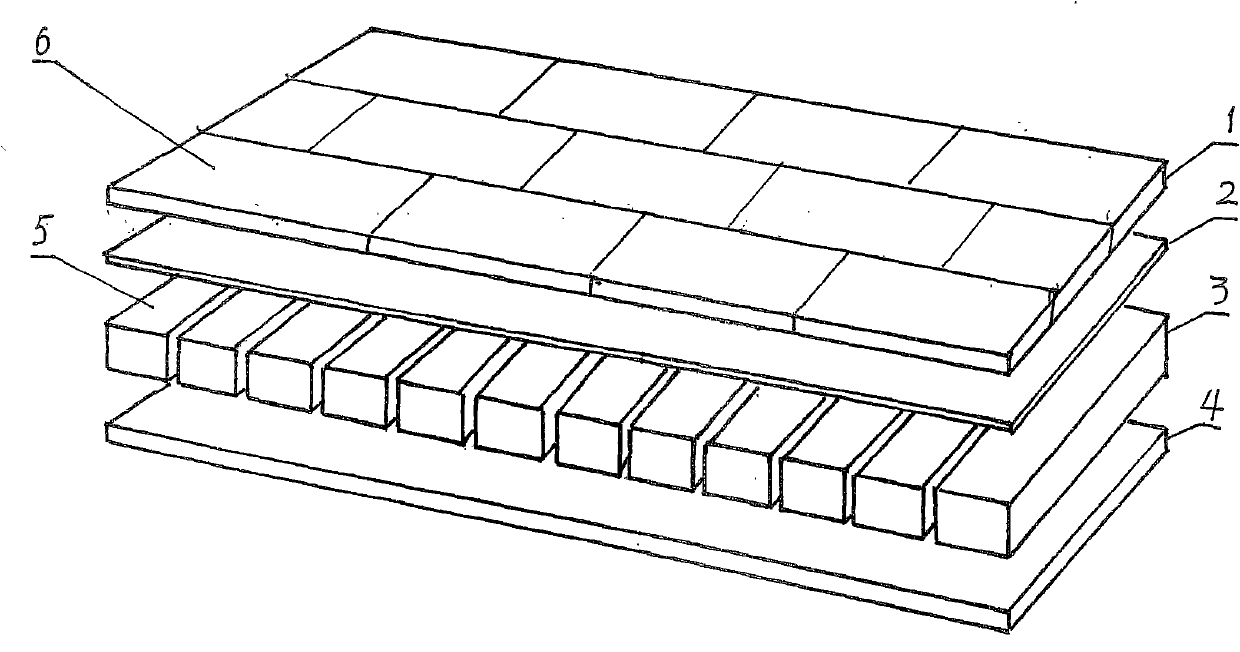

[0017] The present invention is described in detail below in conjunction with embodiment: set out from the applicant's geographical environment and material distribution situation, consider comprehensive factors such as the performance index required by the floor, the easy-to-get situation of wood and the cost of raw materials, and provide the best implementation Example is: surface layer 1 uses oak, is grown into the whole board of 2.2m by splicing the small thin board 6 that is 3mm, wide 150mm, long 350mm by thickness, each small thin board 6 such as figure 1 Dislocation splicing as shown; buffer layer 2 uses poplar veneer with the same length and width as the panel, and a thickness of 0.8mm; core layer 3 uses rectangular fir slats 5, each strip is 40mm wide and 9mm thick, and the intervals are parallel to each other Laying, the distance between two adjacent slats is 3-5mm, and the overall area occupied by the paving is consistent with the surface layer and buffer layer; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com