Dual-heater mobile-heat-shield type Czochralski crystal growing furnace

A heater and single crystal furnace technology, which is applied in the directions of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of difficult to control the temperature gradient of crystal and melt, low energy utilization rate of heater, etc. The effect of stable free liquid surface, reduced argon consumption, and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

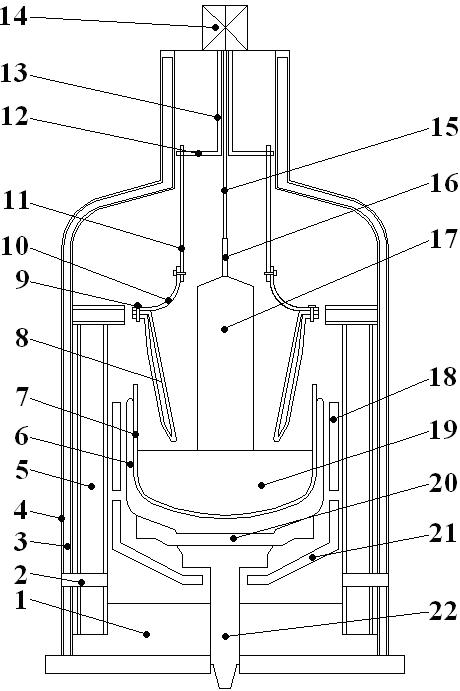

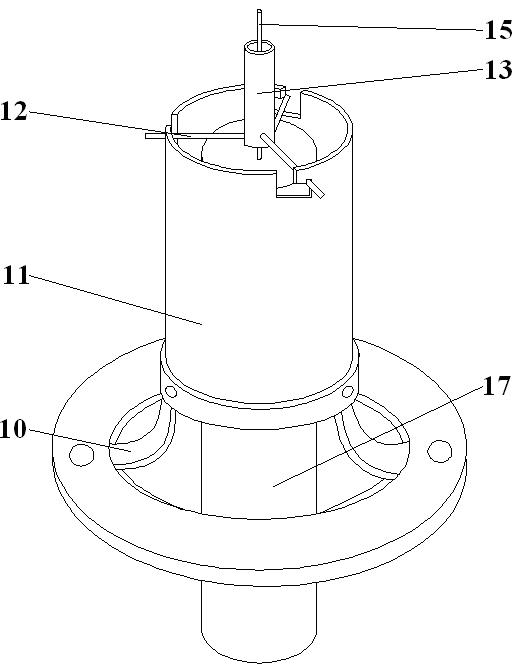

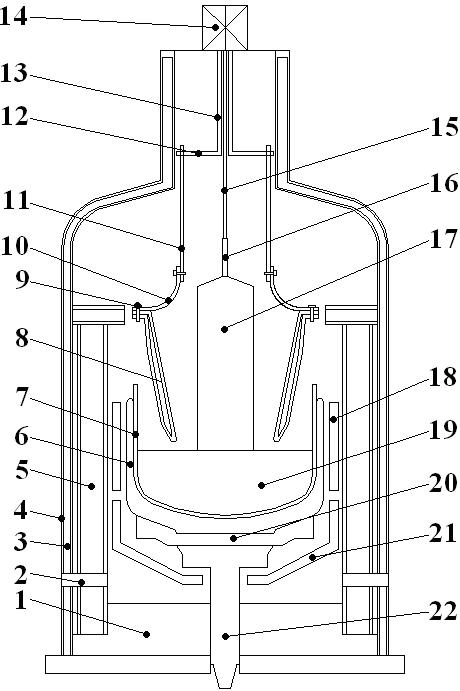

[0017] As shown in the figure, the stainless steel furnace body 4 is an axisymmetric structure, and the stainless steel furnace body 4 and the water-cooling structure 3 constitute the outer frame of the entire single crystal furnace. Servo motor 14 is installed on the top of stainless steel furnace body 4, seed crystal pull rod 15 and concentric sleeve pipe 13 are coaxial with stainless steel furnace body 4, both are installed on the lower end of servo motor 14, seed crystal pull rod 15 passes through concentric sleeve pipe 13, and The seed crystal 16 is clamped at the lowermost end of the seed crystal rod 15 . The servo motor 14 controls the lift and rotation of the seed pull rod 15 and controls the lift of the concentric sleeve 13 at the same time. The bottom end of the concentric sleeve 13 is uniformly welded with three connecting rods 12 along the circumferential direction, the three connecting rods 12 are connected with the slots on the upper part of the guide tube 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com