Preparation method for synthesizing carbon nanotubes in quantity and with low cost

A technology for synthesizing carbon and nanotubes, applied in nanotechnology and other directions, can solve the problems of complex process, limited engineering application, high energy consumption, etc., and achieve the effect of simple preparation process, easy implementation of conditions, and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The steps of the preparation method for low-cost mass synthesis of carbon nanotubes are as follows:

[0015] 1) At room temperature, put nickel foam in an electronic universal testing machine, compact it with a pressure of 3.6MPa, cut it into several pieces of 20mm×40mm or 20mm×60mm in size, put it into an ultrasonic cleaner and clean it with ethanol , then wash it several times with deionized water and dry it; heat the plating solution containing the metal catalyst to 80-90°C, put the cleaned foamed nickel into the plating solution, and plate for 20-30 minutes. Enter into baking oven and dry, obtain the nickel foam sample that contains metal catalyst;

[0016] 2) Place the sample of 20mm×40mm or 20mm×60mm containing metal catalyst nickel foam horizontally or vertically in the quartz boat, push the quartz boat into the quartz tube of the horizontal resistance furnace, and inject nitrogen gas with a flow rate of 200ml / min, When the temperature reaches 650°C, lower the f...

Embodiment 1

[0024] Take a 20×40mm nickel foam and weigh it as 235mg, put it into the plating solution heated to 80°C, put it into the oven for 30 minutes after plating, and dry it in an oven, and weigh it as 265mg.

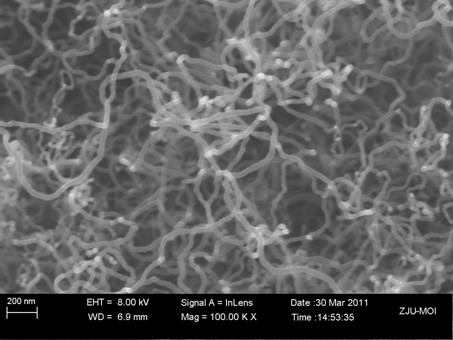

[0025] Place the nickel foam sample crossing the iron horizontally in a quartz boat, heat it with an ordinary horizontal resistance furnace, and feed in N at a flow rate of 200ml / min. 2 Degas the quartz tube. When the temperature reaches 650°C, turn down the N 2 The flow rate reaches 50ml / min, and 50ml / min of H 2 Restore for 10 minutes. When the temperature reaches 690°C, feed 50ml / min of C 2 h 2 , adjust H 2 The flow is closed after 30 minutes of reaction at 50 ml / min C 2 h 2 and H 2 Valve. Increase N 2 The flow rate is up to 200ml / min. Turn off N when the temperature drops to 300°C 2 valve, after the furnace is cooled to room temperature, the quartz boat is taken out, and the total weight of the product to be obtained is 980mg. The SEM photograph of the product ...

Embodiment 2

[0027] Take a piece of 20×40mm nickel foam and weigh it as 235mg, put it into the plating solution heated to 90°C, put it into the oven for 20 minutes after plating, and dry it in an oven, and weigh it as 250mg.

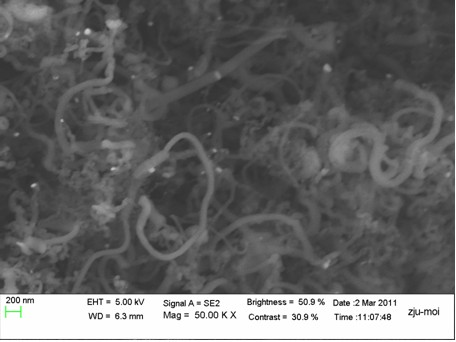

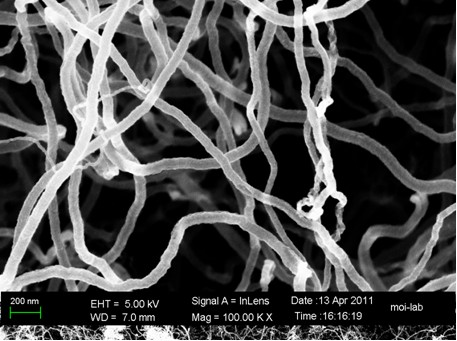

[0028] Place the nickel foam sample crossing the iron horizontally in a quartz boat, heat it with an ordinary horizontal resistance furnace, and feed in N at a flow rate of 200ml / min. 2 Degas the quartz tube. When the temperature reaches 650°C, turn down the N 2 The flow rate reaches 50ml / min, and 50ml / min of H 2 Reduce for 10 minutes, when the temperature reaches 700°C, feed 100ml / min of C 2 h 2 , turn off C after 30 minutes of reaction 2 h 2 Valve, increase N 2 The flow rate is up to 200ml / min. Turn off N when the temperature drops to 300°C 2 Valve, after the furnace is cooled to room temperature, the quartz boat is taken out, and the total weight of the product that can be obtained is 1690mg. The product is a carbon nanotube, and its SEM picture is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com