High-temperature aluminum alloy base rare earth thick film circuit electric heating element and preparation technology thereof

A technology of electric heating element and rare earth thick film, which is applied to heating element materials, conductive materials dispersed in non-conductive inorganic materials, etc., to achieve the effects of easy molding, high thermal efficiency and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

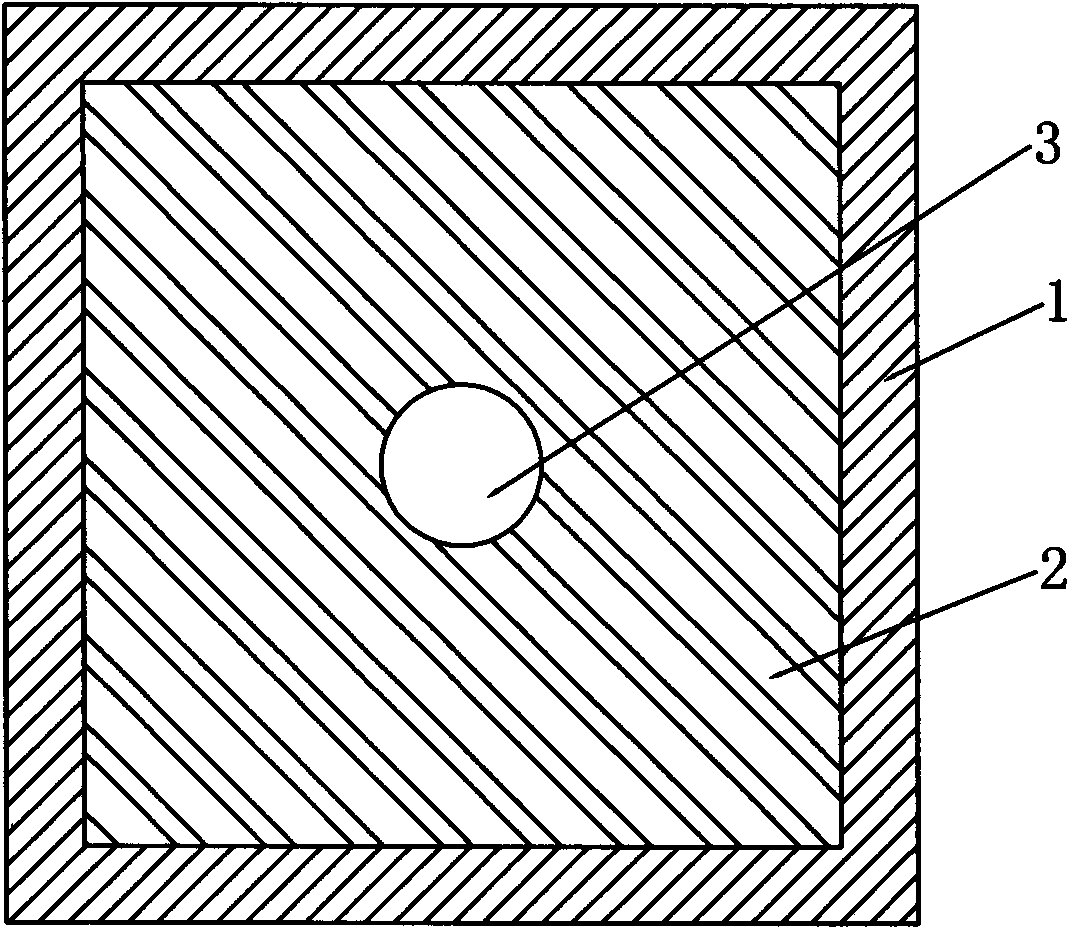

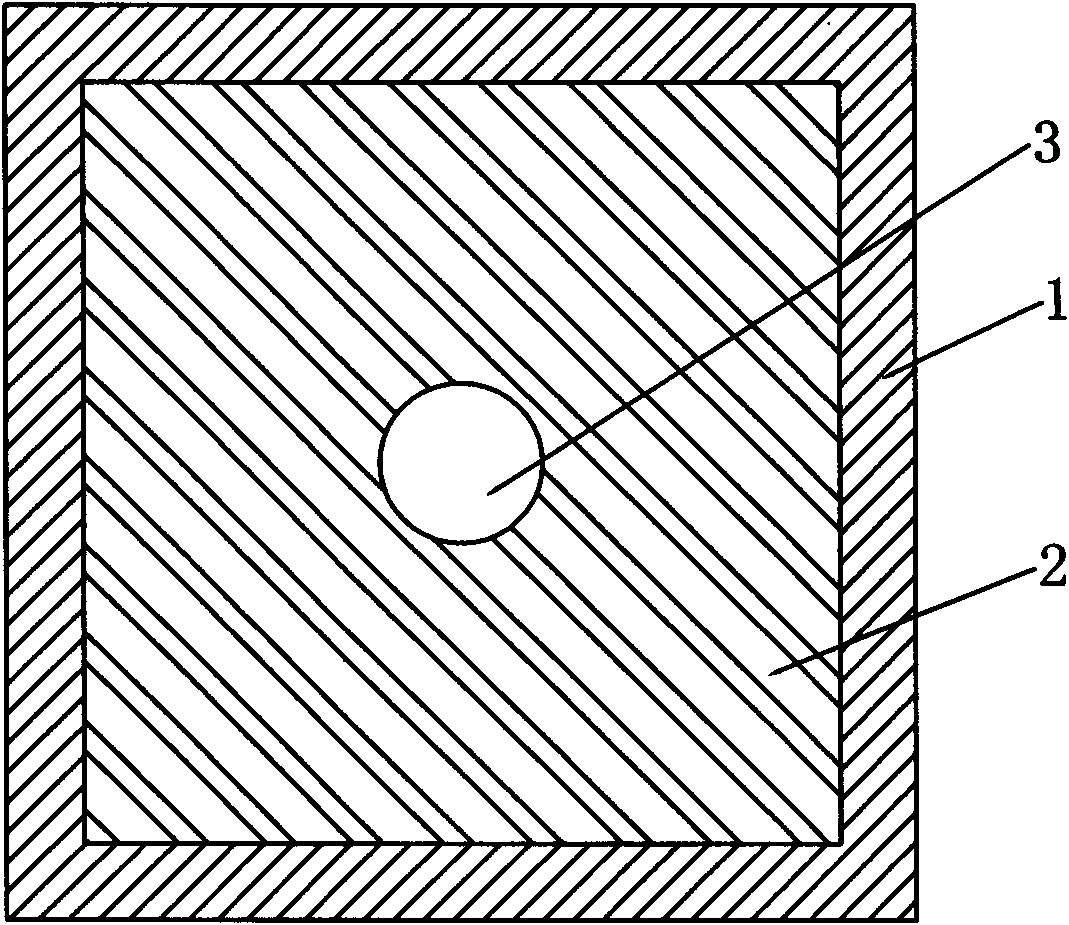

[0033] Such as figure 1 As shown, a rare earth thick film circuit controllable electric heating element based on an aluminum alloy substrate of the present invention includes a substrate and a series of rare earth electronic pastes. The substrate uses an aluminum alloy substrate and the series of rare earth electronic pastes are prepared in the form of thick film circuits. On the aluminum alloy substrate, the dielectric layer 1, the resistance layer 2 and the conductor layer 3 are arranged in sequence from the outside to the inside. Among them, the series of rare earth electronic pastes are composed of three parts: functional phase, inorganic bonding phase, and organic solvent carrier. A dielectric thick film with insulating properties is prepared on the surface of the aluminum alloy substrate, and the rare earth resistance slurry and the rare earth electrode slurry are prepared on the dielectric film in the form of a thick film circuit. The aluminum alloy contains 2 to 7% by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com