Case for combined scale and method for manufacturing same

A manufacturing method and technology of combined scales, applied to the detailed information of weighing equipment, measuring devices, instruments, etc., can solve the problems of chassis size, shape inconsistency, unsuitability for mass production, and uncompact connection of plates, etc., to reduce welding The difficulty of the process, the convenience of large-scale mass production, and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

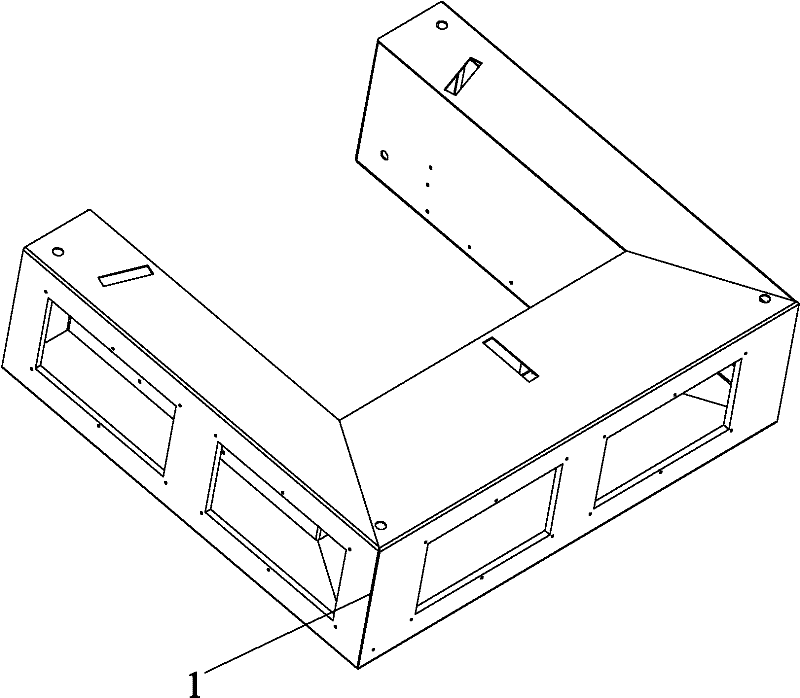

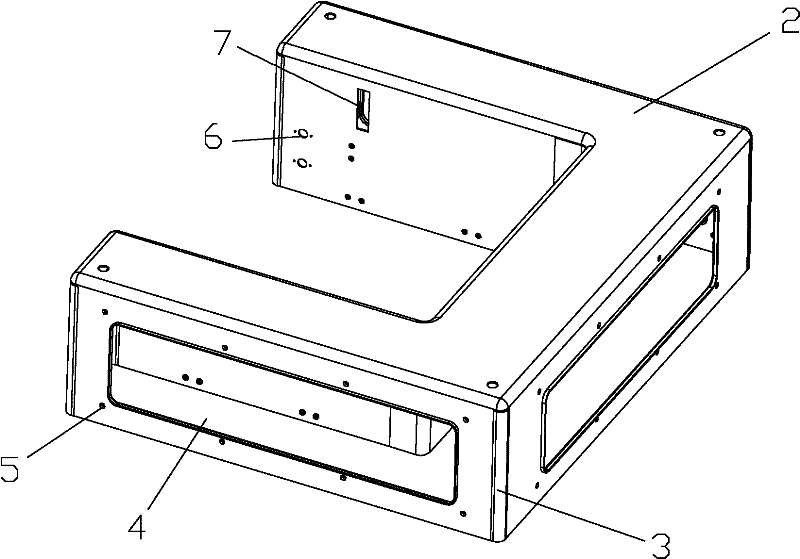

[0045] The manufacturing method of the cabinet for the combination scale adopts the mold stamping forming process to punch out the main cabinet, and then joins the sealing structure of the cabinet for the combination scale by supplementing the lower bottom plate, the inner wall board and the stamped corner plate into an arc shape, so as to complete the cabinet for the combination scale The manufacture specifically includes the following steps:

[0046] (1) According to the expansion size of the designed chassis, accurately cut out the contour line of the required material plate from the stainless steel plate at a ratio of 1:1, mainly cutting out the main chassis plate, lower bottom plate, inner wall plate and corner plate. .

[0047] (2) Hole flanging:

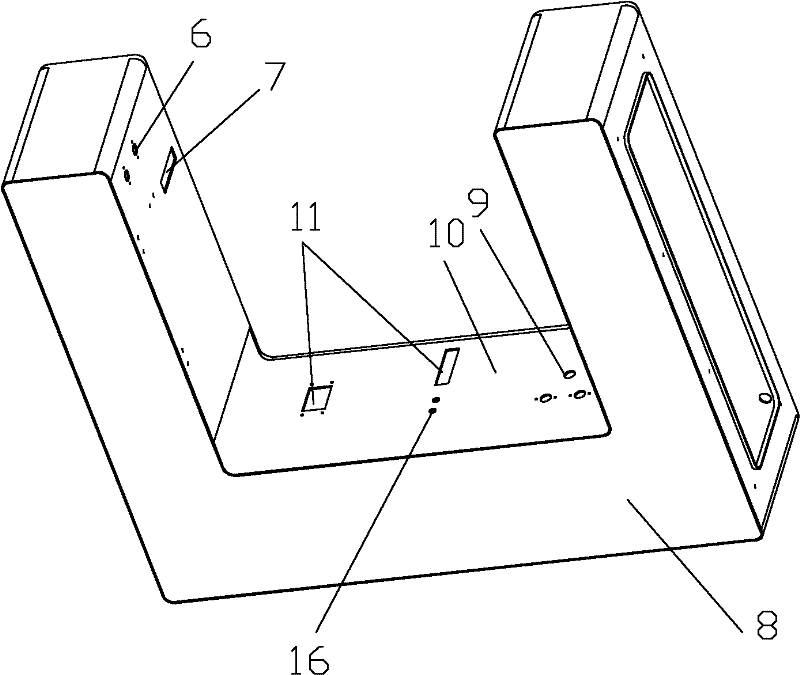

[0048](2-1) In this embodiment, a punching die is used to open holes, and an installation window 4, an installation hole 6, and an installation hole 7 are formed on the main chassis plate that has obtained an accurate contour...

Embodiment 2

[0060] This embodiment has the same characteristics as Embodiment 1 except for the following features: in the step (3), the pressure holding time is 2 seconds.

[0061] In the step (2), the installation window 4, the installation hole 6, and the installation hole 7 are opened at the corresponding position of the main chassis plate by laser technology, and the installation hole 11 is opened at the corresponding position of the inner wall plate. Hole 9: use a tapping machine to drill threaded holes 5 and 16 at the corresponding positions of the main body chassis plate and the inner wall plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com