Mineralized corn protein fibrous membrane and preparation method thereof

A corn gluten fiber, corn gluten technology, applied in fiber processing, fiber chemical characteristics, single-component protein rayon and other directions, can solve the complex purification process of natural polymer collagen, and the safety and effect of recombinant human collagen are yet to be solved. Inspection and high cost problems, to achieve the effect of wide source of raw materials, good biocompatibility and biodegradability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

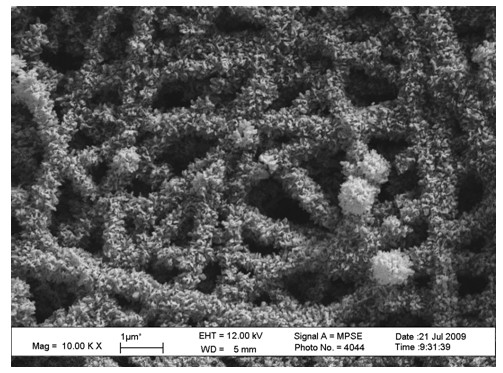

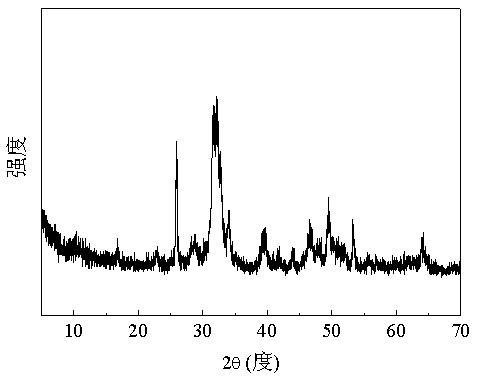

[0028] Example 1 Dissolve 3 grams of zein in 10 mL of a mixed solvent of ethanol and water, the volume ratio of ethanol and water is 70:30, and make a 30% (w / v) polymer solution, add it to the storage tank, pass A pump or conduit is connected to the spray head,

[0029] Perform electrospinning. The spray head is connected to a DC high-voltage electric field, the voltage is positive 15 kV, the distance between the spray head and the receiving object is controlled at 10 cm, the solution flow rate is 6 mL / h, and the receiving device is grounded. The zein fibers are randomly stacked to obtain a fibrous film. —4—

[0030] Soak the zein fiber film in 0.01 mol / L acetic acid solution for 30 minutes, 0.5 mol / L calcium chloride solution for 30 minutes, and 0.3 mol / L ammonium dihydrogen phosphate solution for 30 minutes. After the soaking is completed, the fiber membrane is taken out, and after repeated water washing and freeze-drying, the mineralized zein fiber membrane is obtained. ...

Embodiment 2

[0031] Example 2 Dissolve 5 grams of zein in 10 mL of a mixed solvent of methanol and water, the volume ratio of methanol and water is 60:40, make a 50% (w / v) polymer solution, add it to the storage tank, pass A pump or catheter is connected to the spray head for electrospinning. The spray head is connected to a DC high voltage electric field, the voltage is positive 10 kV, the distance between the spray head and the receiving object is controlled at 10 cm, the solution flow rate is 20 mL / h, and the receiving device is grounded. The zein fibers are randomly stacked to obtain a fibrous film. After the zein fiber membrane was crosslinked in 2.5 wt% glutaraldehyde solution for 24 hours, it was soaked in 0.02 mol / L acetic acid solution for 30 minutes. The cross-linked zein fiber membrane was immersed in 0.5 mol / L calcium chloride solution for 30 minutes, followed by 0.3 mol / L sodium dihydrogen phosphate solution for 30 minutes, and this was regarded as a cycle, soaking for 3 cycl...

Embodiment 3

[0032] Example 3 Dissolve 4 grams of zein in 10 mL of a mixed solvent of ethanol and water. The volume ratio of ethanol and water is 70:30 to form a 40% (w / v) polymer solution. Add 1.5 mL of 0.05 mg / mL bone morphogenetic protein (BMP-2) in phosphate buffered saline (PBS), stir well. Add the mixed solution into the storage tank, connect it to the spray head through a pump or catheter, and perform electrospinning. The spray head was connected to a DC high-voltage electric field with a voltage of minus 12 kV, the distance between the spray head and the receiver was controlled at 10 cm, the solution flow rate was 6 mL / h, and the receiving device was grounded. After immersing zein fiber in 0.01 mol / L acetic acid solution for 20 minutes, soak in 0.15 mol / L calcium chloride solution for 15 minutes, then in 0.09 mol / L ammonium dihydrogen phosphate solution for 15 minutes, and use this as a cycle , Soak for 3 cycles. After the soaking is completed, the fiber membrane is taken out, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com