Acid etching treatment solution and treatment method for aluminum and aluminum alloy products

A treatment method and treatment liquid technology are applied in the acid etching treatment liquid and treatment field of aluminum and its alloy products, which can solve the problems of fast change of reaction rate, low treatment efficiency, and many generation, and achieve easy detection and analysis, easy control, The effect of simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

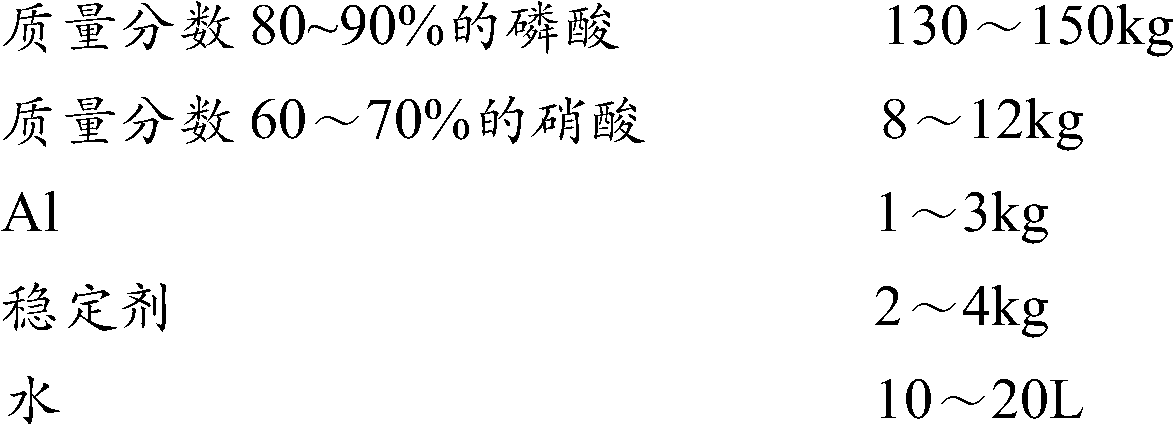

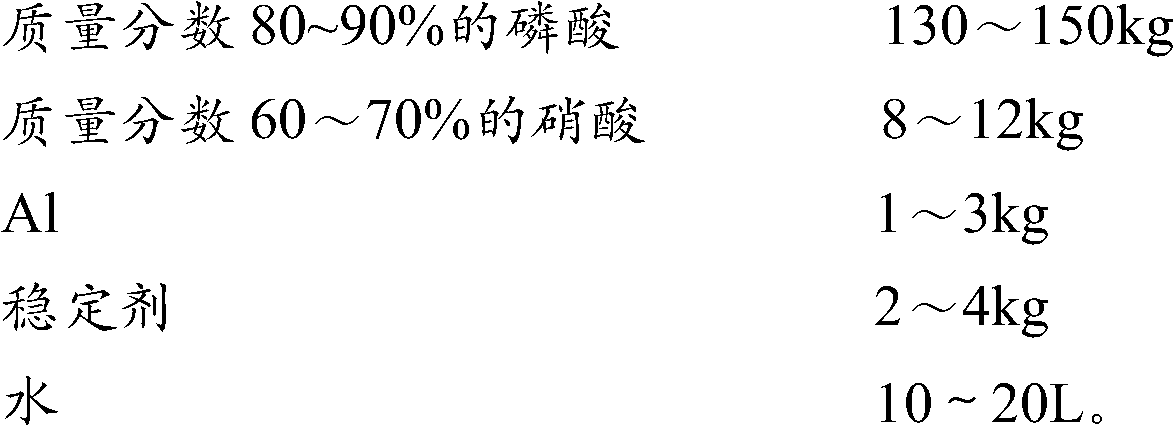

Method used

Image

Examples

Embodiment 1

[0019] Take the preparation of 100L acid etching treatment liquid as an example, first pour 3 barrels of phosphoric acid (35Kg / barrel, mass fraction 85%) into the reaction kettle, then add 8L nitric acid (mass fraction 63%), and dissolve 500g with a small amount of hot water Ammonium acetate, 500g of copper acetate, and 1kg of carbonyl diamide are mixed into the above acid solution, and the temperature is raised to 100-110°C. At the same time, 1kg of "clean" (grease-removed) metal aluminum is added (add in 2-3 times) 10L of water was added in batches during the process of dissolving aluminum. After the aluminum was dissolved, a bucket of phosphoric acid was added, and the volume was fixed with water. The specific gravity was 1.68kg / L (measured at 80°C).

Embodiment 2

[0021] Taking the preparation of 100L acid etching treatment solution as an example, first pour 100kg of phosphoric acid (mass fraction 85%) into the reactor, then add 8L of nitric acid (mass fraction 63%), and dissolve 500g of ammonium acetate and 500g of acetic acid with a small amount of hot water. After copper and 1kg of carbonamide, mix them into the above acid solution, raise the temperature to 100-110°C, and add 1kg of "clean" (grease-removed) metal aluminum at the same time (adding in 2-3 times). A total of 12L of water was added in batches. After the aluminum was dissolved, a bucket of phosphoric acid was added, and the volume was adjusted with water. The specific gravity was 1.65kg / L (measured at 80°C).

Embodiment 3

[0023] Taking the preparation of 100L acid etching treatment solution as an example, first pour 95kg of phosphoric acid (mass fraction 85%) into the reactor, then add 6L of nitric acid (mass fraction 63%), and dissolve 1kg of ammonium acetate and 1kg of acetic acid with a small amount of hot water. Copper and 2kg of carbonyl diamide are mixed into the above acid solution, and the temperature is raised to 100-110°C. At the same time, 2kg of "clean" (grease-removed) metal aluminum is added (added in 2-3 times). Add water in batches to a total of 15L. After the aluminum is dissolved, add a bucket of phosphoric acid, and use water to make up the volume. The specific gravity is 1.60kg / L (measured at 80°C).

[0024] Treat 1070 drawn aluminum products with the above treatment solution:

[0025] Put the 1070 stretched aluminum middle beam (the lipstick tube part) in the acidic degreasing solution (phosphoric acid 35g / L, 2-butoxyethanol 70mL / L) for 1 minute, take it out and wash it wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com