Process and device for recycling coked ammonium sulfate acid tar

A technology of acid tar and tar, which is applied in the recovery and treatment process of coking ammonium sulfuric acid tar and its device field, can solve the problems of sewage treatment system paralysis, failure to meet discharge standards, large-scale industrial clear water, etc., and solve the problem of difficult treatment of acid tar, Realize the effect of recycling and increasing tar production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

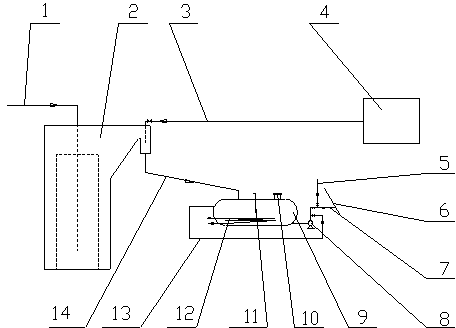

[0021] A kind of coking ammonium sulfate acid tar recycling process and its device provided by the present embodiment, the device is connected as figure 1 As shown, it includes ammonia water heat exchanger 4 for distilling ammonia, ammonium sulfate full flow tank 2 and acid tar neutralization tank 9, ammonium sulfate full flow tank 2 is connected with full flow pipe 1, and ammonium sulfate full flow tank 2 tar port passes through the pipeline 14 is connected with the acid tar neutralization tank 9, and the hot ammonia water pipeline of the ammonia water heat exchanger 4 leads a branch pipe 3 to the tar port of the ammonium sulfate full flow tank 2, and is close to the ammonium sulfate full flow tank 2 tar port on the branch pipe 3 A valve is installed to adjust the amount of hot ammonia water. When the tar in the full flow tank 2 is taken out, the hot ammonia water from the ammonia water heat exchanger 4 is opened in a small amount in time (the volume ratio of the amount of amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com