Electric boosting electrode device

An electrode device and electric boosting technology, applied in electric furnaces, furnace types, furnaces, etc., can solve the problems of chemical erosion and physical wear of refractory materials, accelerated electrode port material damage, material temperature rise, etc., to achieve simple structure, reduce The difficulty of material selection and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

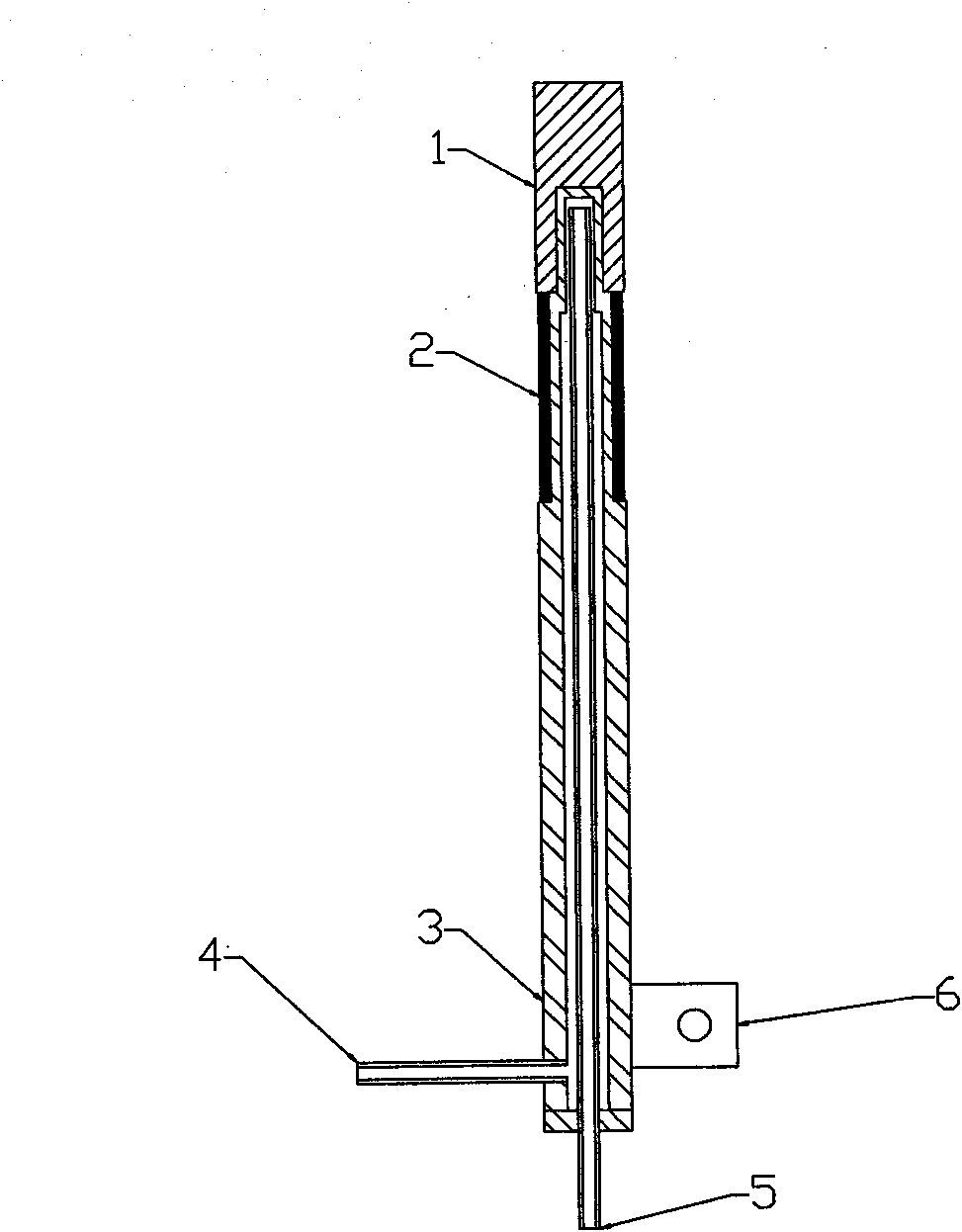

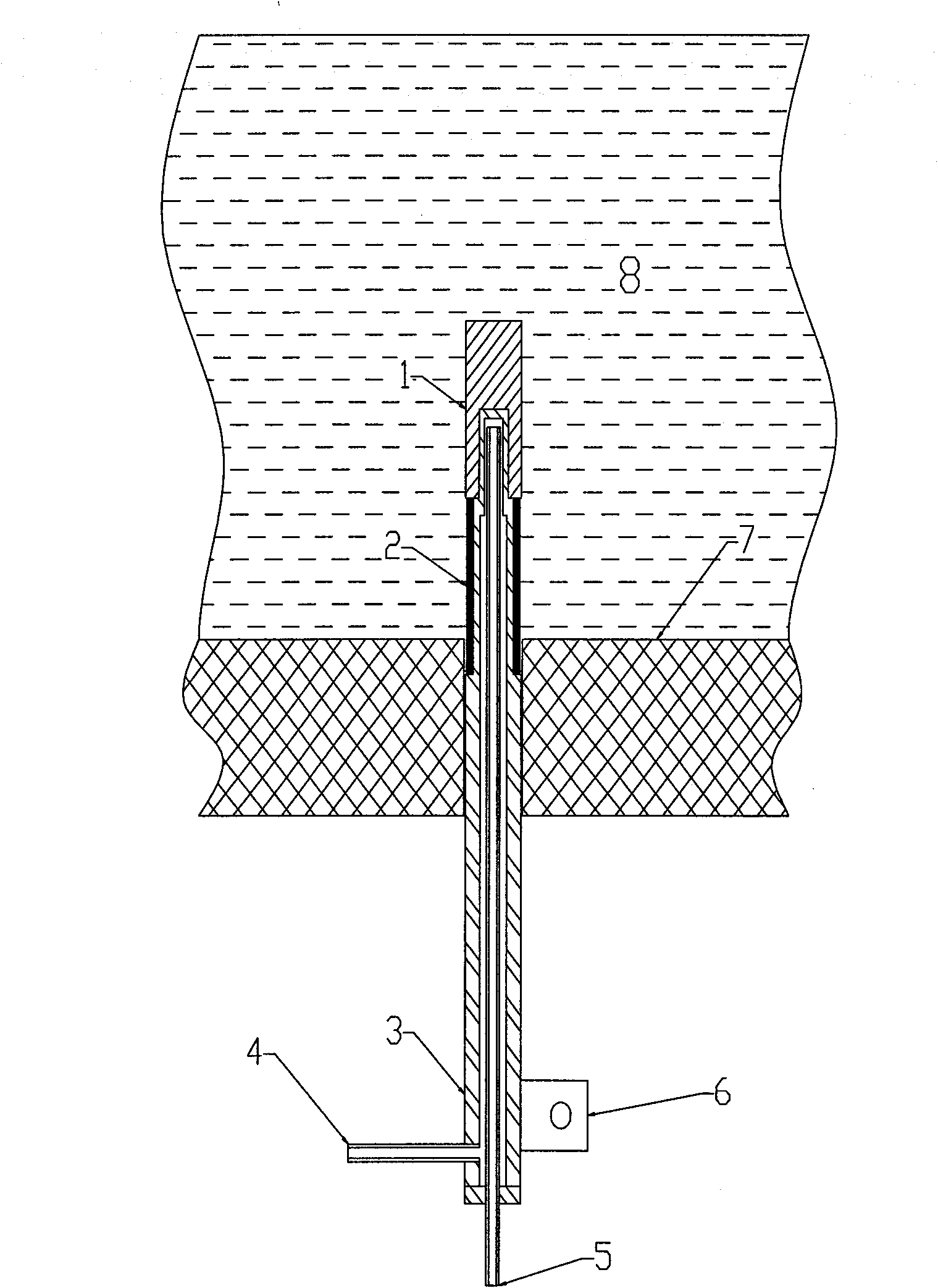

[0020] Such as figure 2 As shown, the material of the electrode head (1) is molybdenum metal, the shape is cylindrical, the diameter is 60mm, the length is 500mm, and the center of the lower end is processed with an internal thread with a depth of 40mm and a middle diameter of 40mm; the insulating sleeve (2) is a 99 alumina ceramic tube , outer diameter 55mm, wall thickness 3mm, length 200mm.

[0021] The cooling water pipeline (3) is made of heat-resistant stainless steel, with an upper length of 40 mm and an external thread with a middle diameter of 40 mm; a middle outer diameter of 47 mm and a length of 200 mm; a lower outer diameter of 60 mm and a length of 1500 mm, with an inlet pipe (5) for water supply and return Water pipe (4) outlet, used water adopts demineralized circulating water, and the control water temperature is not higher than 60 ℃. The electrical wiring board (6) is made of T1 electrolytic copper, which is welded on the outer diameter of the cooling water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com