Full-frequency response theory and technology application in violin manufacturing

A violin and theoretical technology, applied to instruments, stringed instruments, musical instruments, etc., can solve problems such as unbalanced violin pronunciation, reduce the difficulty of material selection, facilitate mechanized production, and achieve the effect of balanced and loud pronunciation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0019] The specific implementation of the present invention will be described in detail below with reference to specific embodiments.

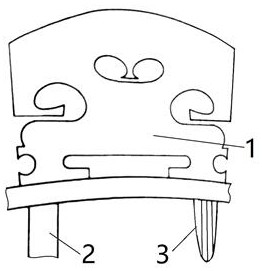

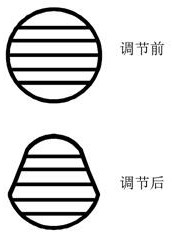

[0020] like Figure 1-4 As shown, the theory and technical application of full frequency response in violin making provided by an embodiment of the present invention include:

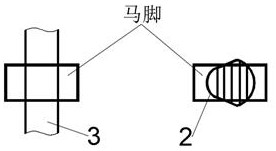

a soundboard, the soundboard includes a front panel and a back panel, and a sound column 2 is provided between the front panel and the back panel;

Bass beam 3, described bass beam 3 is used for supporting panel and dividing bass vibration area;

The bridge 1 is arranged on the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com