A method of co-producing high-purity Schaeffer's salt and g-salt

A technology of Schaeffer's salt and naphthol, which is applied in the field of co-production of Schaeffer's salt and G salt, can solve the problems of low utilization rate of raw materials, difficult purification of finished products, and low yield of G salt, so as to improve the overall utilization rate , Process environmental protection, high product purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

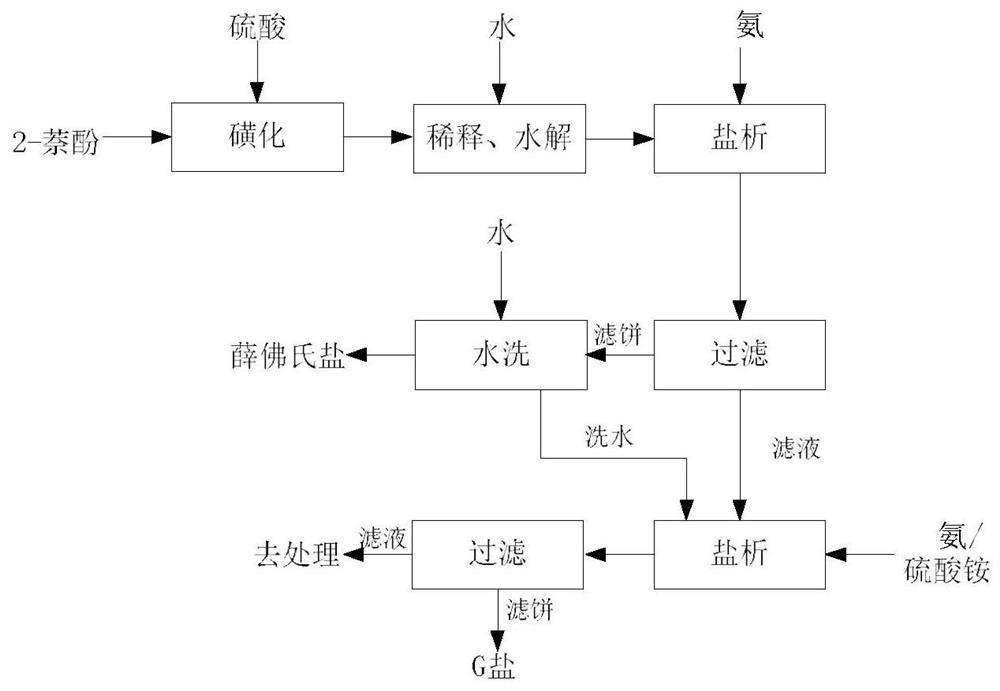

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for simultaneously preparing and separating high-purity Schaeffer's salt and G salt, comprising the following steps:

[0035] Take 100g of 2-naphthol, add 300g of 98.5% sulfuric acid, react at 50°C for 4 hours, add 130g of water to adjust the acidity for hydrolysis, control the addition temperature at 80-85°C, keep it warm for 2 hours, then add 50g of 20% ammonia water for salting out, Control the addition temperature at 100-105°C, keep warm for 2 hours after the addition, cool down to 40-50°C and press filter to obtain 100g of Schaeffer's salt crude product and 480g of mother liquor, add 100g of water to the Schaeffer's salt crude product for washing, and obtain 88g Schaeffer's salt finished product, purity 99.77%. After mixing the washing water with the mother liquor of Schaeffer's salt, add 150g of 20% ammonia water, keep it at 80°C for 2 hours for salting out, then cool down to 40-50°C and filter and separate to obtain 105g of finis...

Embodiment 2

[0037] This embodiment provides a method for simultaneously preparing and separating high-purity Schaeffer's salt and G salt, comprising the following steps:

[0038] Take 100g of 2-naphthol, add 300g of 98.5% sulfuric acid, react at 65°C for 5 hours, add 150g of water to adjust the acidity for hydrolysis, control the addition temperature at 80-85°C, keep it warm for 2 hours, then add 60g of 20% ammonia water for salting out, Control the addition temperature at 100-105°C, keep warm for 1h after the addition, cool to 40-50°C and press filter to obtain 85g of Schaeffer's salt crude product and 525g of mother liquor, add 280g of water to the Schaeffer's salt crude product for washing, and obtain 70g Schaeffer's salt finished product, purity 99.87%. After mixing the washing water with the mother liquor of Schaeffer's salt, add 150g of 20% ammonia water, incubate at 90°C for 1 hour for salting out, then cool down to 40-50°C and filter and separate to obtain 115g of finished G salt ...

Embodiment 3

[0040] This embodiment provides a method for simultaneously preparing and separating high-purity Schaeffer's salt and G salt, comprising the following steps:

[0041] Take 100g of 2-naphthol, add 300g of 97% sulfuric acid, react at 80°C for 6 hours, add 150g of water to adjust the acidity for hydrolysis, control the addition temperature at 80-85°C, keep it warm for 2 hours, then add 70g of 20% ammonia water for salting out, Control the addition temperature at 100-105°C, keep warm for 2 hours after the addition, cool down to 40-50°C and press filter to obtain 62g of Schaeffer's salt crude product and 558g of mother liquor, add 200g of water to the crude Schaeffer's salt for washing, and obtain 54g Schaeffer's salt finished product, purity 99.8%. After mixing the washing water with the Schaeffer’s salt mother liquor, add 150g of 20% ammonia water, keep it at 100°C for 2h for salting out, then cool down to 40-50°C and filter and separate to obtain 128g of G salt finished product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com