Method and device for continuously synthesizing spherical micro-nano cuprous oxide powder

A technology of cuprous oxide and powder, which is applied in the field of nanomaterials, can solve problems such as agglomeration, particle shape, uncontrollable size, difficulty in batch consistency control, and insufficient particle size distribution. It achieves easy post-processing, simple structure, Good star effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

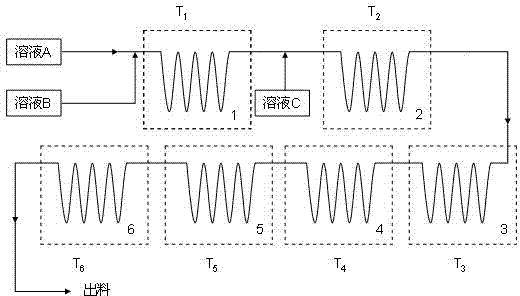

[0037] A segmented tubular reaction device (see figure 1 ), which in turn includes a trident pipe, six sections of tubular heating reactors in series and a discharge pipe; between the trifurcated pipe and the tubular heating reactors, and between the tubular heating reactors in series are connected by pipelines; in the first and second Material input pipes are arranged on the pipes between the two-stage tubular heating reactors. The inner diameter of the tube of the tubular reactor is 4mm, and the total length of the tube is 85m. Except for the first section, which is 10m long, the remaining sections are all 15m.

[0038] Process for continuous synthesis of spherical cuprous oxide powder:

[0039](1) Dissolve copper sulfate pentahydrate, sodium hydroxide and glucose in deionized water respectively to prepare 0.2mol / L copper sulfate solution A, 0.55mol / L sodium hydroxide solution B and 0.11mol / L glucose Solution C.

[0040] (2) Put solution A and solution B into the first-st...

Embodiment 2

[0046] The structure of the sectioned tubular reaction device is the same as in Example 1.

[0047] Process for continuous synthesis of spherical cuprous oxide powder:

[0048] (1) Dissolve copper sulfate pentahydrate, sodium hydroxide and glucose in deionized water respectively, and prepare 0.2mol / L copper sulfate solution A, 0.80mol / L sodium hydroxide solution B and 0.11mol / L glucose Solution C.

[0049] (2) Put solution A and solution B into the first-stage tubular reactor at a speed of 20mL / min with advection pump through the trident tube, and control the temperature T of the first-stage tubular reactor 1 at 25°C.

[0050] (3) Add solution C to the reaction system at a rate of 20mL / min through the pipeline between the first and second tubular reactors;

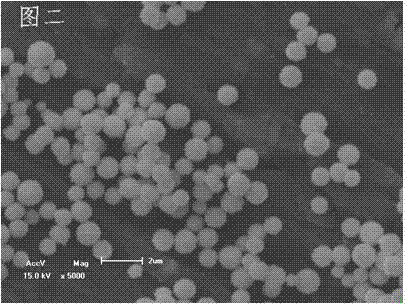

[0051] (4) The mixture system enters the subsequent five-stage tubular reactor at a speed of 60mL / min, and the reaction temperature of each stage is controlled (T 2 , T 3 , T 4 , T 5 , T 6 ) at 40°C, 45°C, 50°C, 55...

Embodiment 3

[0055] The structure of the sectioned tubular reaction device is the same as in Example 1.

[0056] (1) Dissolve copper sulfate pentahydrate, sodium hydroxide and glucose in deionized water respectively, and prepare 0.2mol / L copper sulfate solution A, 0.60mol / L sodium hydroxide solution B and 0.11mol / L glucose Solution C.

[0057] (2) Put solution A and solution B into the first-stage tubular reactor at a speed of 20mL / min with advection pump through the trident tube, and control the temperature T of the first-stage tubular reactor 1 at 30°C.

[0058] (3) Add solution C to the reaction system at a rate of 20mL / min through the pipeline between the first and second tubular reactors;

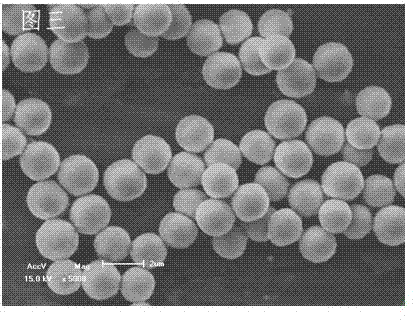

[0059] (4) The mixture system enters the subsequent five-stage tubular reactor at a speed of 60mL / min, and the reaction temperature of each stage is controlled (T 2 , T 3 , T 4 , T 5 , T 6 ) at 50°C, 55°C, 60°C, 65°C and 70°C, respectively.

[0060] (5) The final product of the reaction col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com