Rotary spiral gas anchor

A spiral and gas anchor technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of short validity period of the packer, inability to adapt to high liquid production, low separation efficiency, etc., and achieve frictional resistance Smaller, lower relative speed, better separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

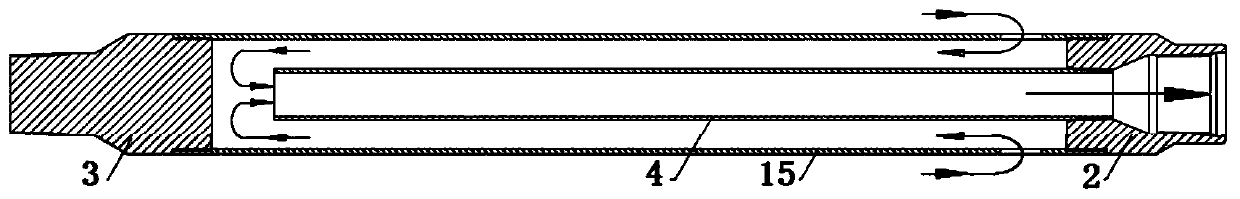

[0037] Such as Figure 6 A rotary screw type air anchor shown includes an anchor housing 1, one end of the anchor housing 1 is provided with an upper joint 2, and the other end is provided with a lower joint 3, and one end of the anchor housing 1 is connected to the upper joint 2 are threaded, and the other end is threaded with the lower joint 3. Internal threads 12 are provided on the inner walls of both ends of the anchor housing 1 , and external threads 13 matching the internal threads 12 are provided on the outer walls of the upper joint 2 and the lower joint 3 . The anchor housing 1 is provided with a central tube 4 extending in the axial direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com