Self-cleaning system for hydrophilicity and hydrophobicity analysis resin and cleaning method

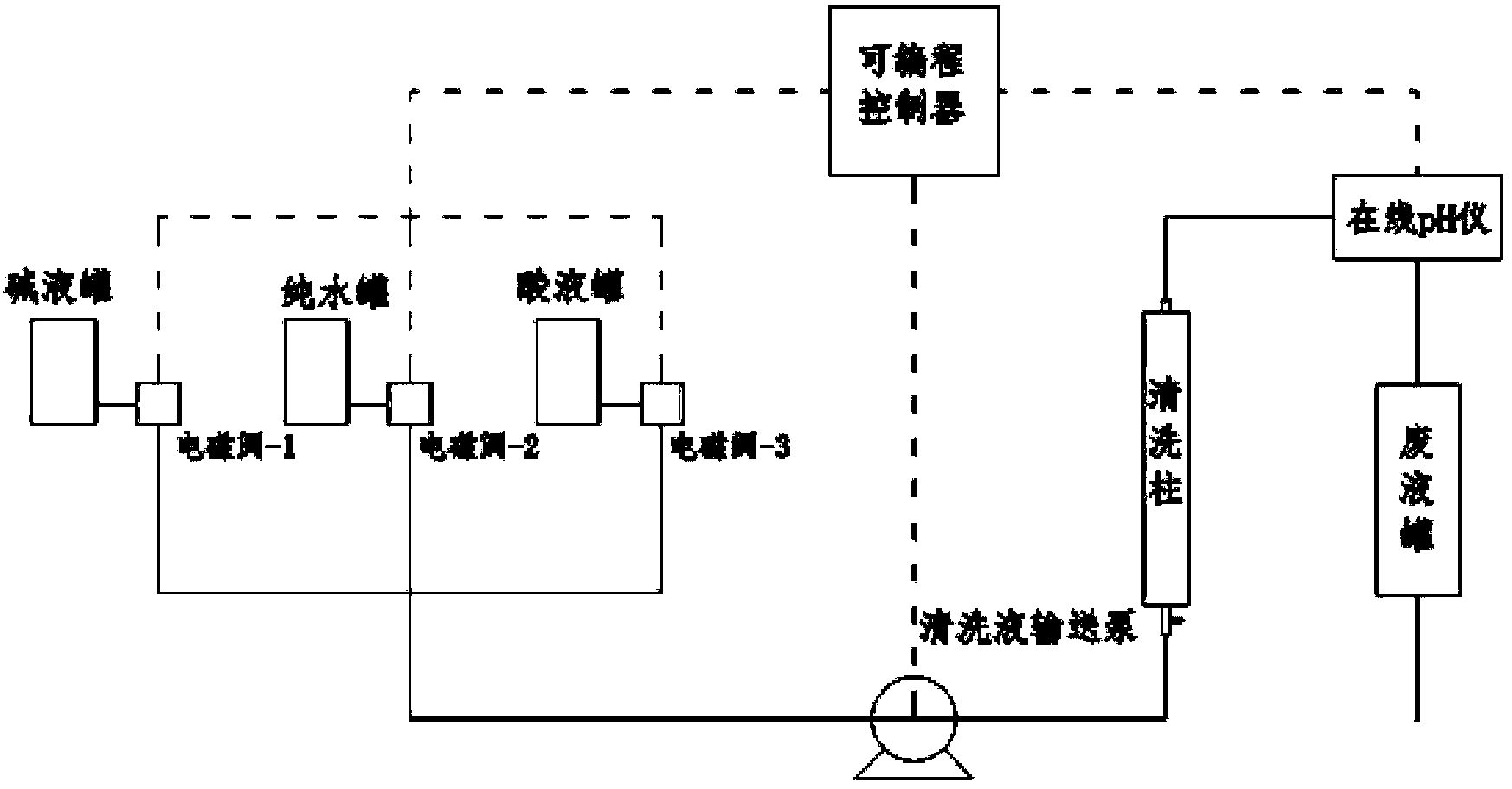

An automatic cleaning and resin technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as poor cleaning effect, cumbersome cleaning process, and poor cleaning airtight conditions, so as to avoid entry and exit The problem of water velocity difference, avoiding back-mixing and cut-off, and reducing the effect of discharge pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

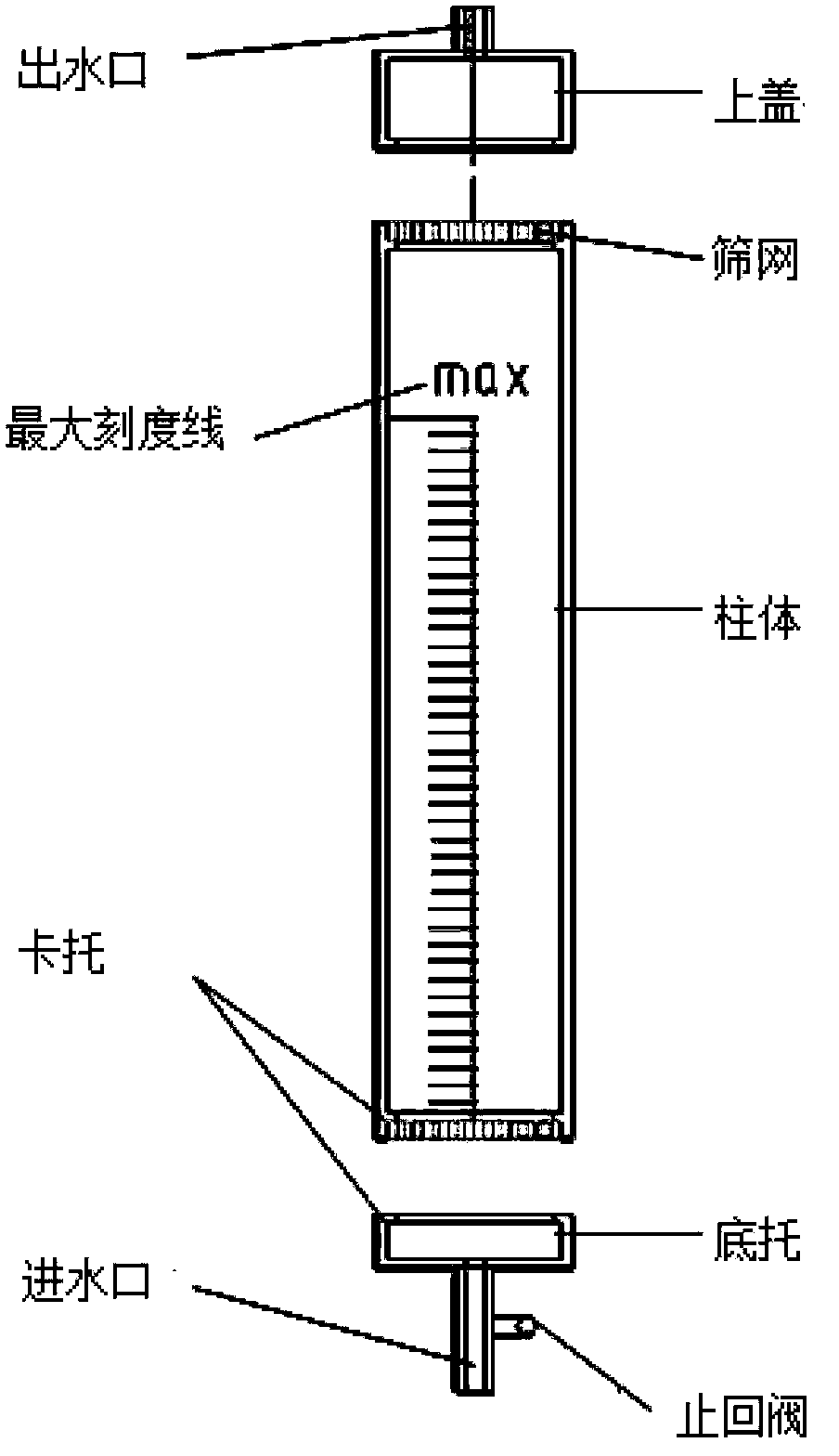

[0025] In this example, the resin to be cleaned is XAD-4 type resin produced by Rohm and Haas Company, the wet volume of the resin is 1L, and the cleaning column with the maximum scale of 1L is selected as the cleaning column. Mix the resin and pure water into the column so that the wet volume of the resin does not exceed the maximum scale line and the pure water level is at least 2cm higher than the stable surface of the resin sedimentation. After the column loading is completed, open the cleaning column check valve, start the cleaning liquid delivery pump to make the cleaning liquid flow rate 15L / h, and enter the cleaning stage at this time: open the solenoid valve-1, and 0.1M cleaning lye NaOH is delivered to the cleaning When the pH of the effluent of the cleaning solution is >12, the programmable controller starts timing. After 24 minutes, NaOH passes through 6L, the solenoid valve-1 is closed, and the solenoid valve-2 is opened, and the pure water is sent to the cleaning ...

example 2

[0027]In this example, the resin to be cleaned is XAD-8 resin produced by Rohm and Haas Company, the wet volume of the resin is 10 mL, and the cleaning column with a maximum scale of 10 mL is selected. Mix the resin and pure water into the column so that the wet volume of the resin does not exceed the maximum scale line and the pure water level is at least 2cm higher than the stable surface of the resin sedimentation. After the column loading is completed, open the cleaning column check valve, start the cleaning solution delivery pump to make the cleaning solution flow rate 30mL / h, and enter the cleaning stage: open the solenoid valve-1, and 0.1M cleaning lye NaOH is delivered to the cleaning When the pH of the effluent of the cleaning solution is >12, the programmable controller starts timing. After 12 minutes, 60mL of NaOH passes through, the solenoid valve-1 is closed, and the solenoid valve-2 is turned on, and the pure water is sent to the cleaning column. When the pH of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com