Method for preparing hydroxyapatite nano-structure microspheres

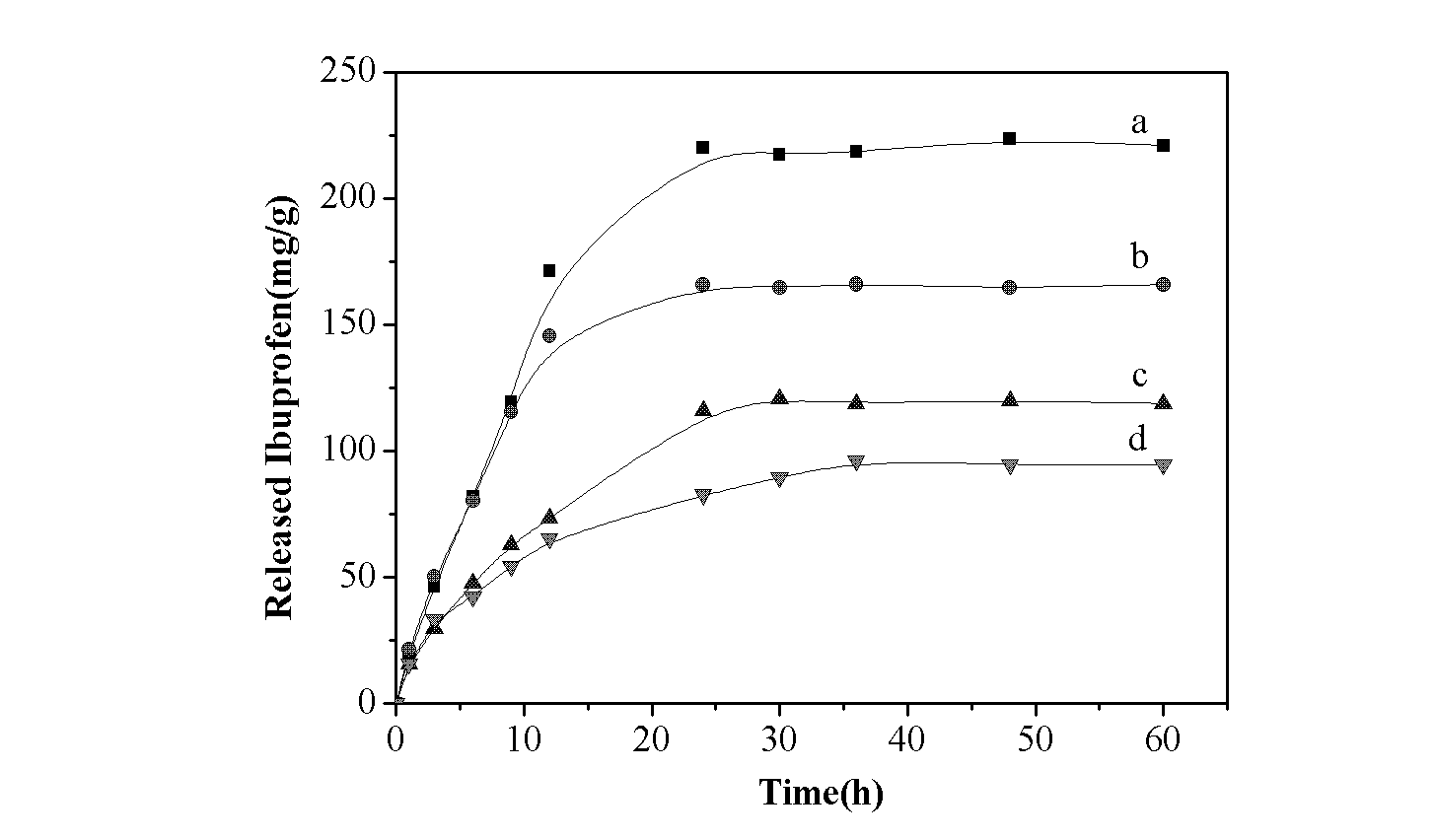

A technology of hydroxyapatite and nanostructure, applied in the direction of nanotechnology, chemical instruments and methods, phosphorus compounds, etc., to achieve obvious slow-release effect, simple preparation process, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of hydroxyapatite nanostructure microspheres in this embodiment is as follows:

[0028]Take 2mL of 0.4mol / L calcium chloride and 2mL of 0.24mol / L diammonium hydrogen phosphate solution and mix, the solution appears turbid, after adjusting the pH of the system to 1 with 1mol / L hydrochloric acid, the solution becomes clear, and the molar ratio n( Urea): n(Ca 2+ )=5:1, n(disodium edetate):n(Ca 2+ )=1:50, V(glycerol):V(H 2 (O)=9:1 add urea, edetate disodium and glycerol, the solution total volume is 40mL after completely dissolving, the concentration of calcium chloride is 0.02mol / L, and the concentration of diammonium hydrogen phosphate is 0.012mol / L , the solution was transferred to a 50mL autoclave, and a solvothermal synthesis reaction was performed at 100° C. for 5 hours to obtain hydroxyapatite nanostructure microspheres.

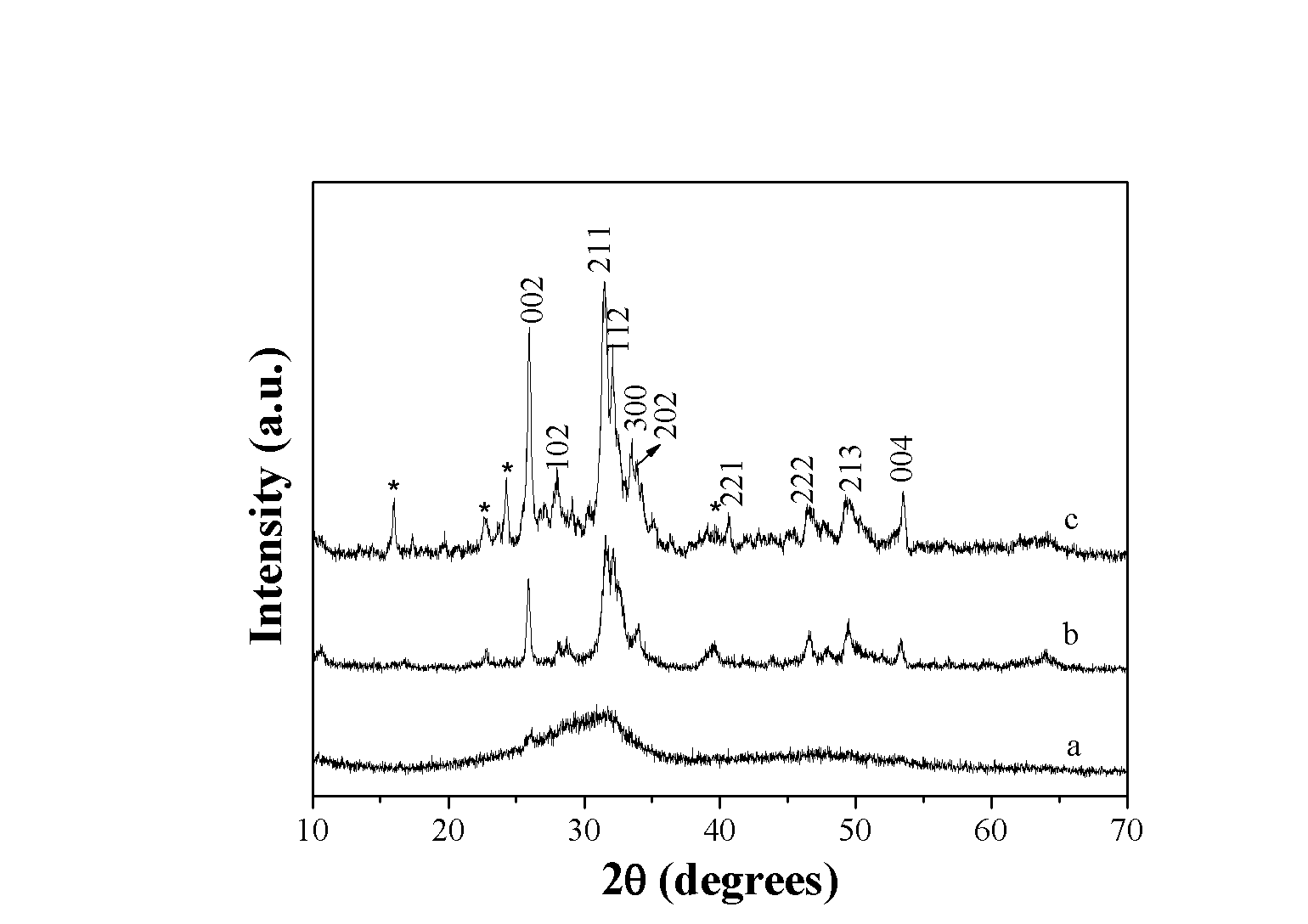

[0029] Depend on figure 1 a and figure 2 a, b analysis shows that the product is a hexagonal hydroxyapatite hollow na...

Embodiment 2

[0031] The preparation method of hydroxyapatite nanostructure microspheres in this embodiment is as follows:

[0032] Take 10mL of 0.4mol / L calcium chloride and 10mL of 0.24mol / L diammonium hydrogen phosphate solution and mix respectively, the solution appears turbid, after the pH of the system is adjusted to 0.5 with 2mol / L hydrochloric acid, the solution becomes clear, and the molar ratio n( Urea): n(Ca 2+ )=3:1, n(citric acid):n(Ca 2+ )=1:30, V(glycerol):V(H 2 (2)=1:1 add urea, citric acid and glycerol, after dissolving completely, total solution volume is 40mL, and calcium chloride concentration is 0.1mol / L, and diammonium hydrogen phosphate concentration is 0.06mol / L, and solution is transferred to A 50mL autoclave adopts a solvothermal synthesis reaction at 85°C for 10 hours to obtain hydroxyapatite nanostructured microspheres.

[0033] Depend on figure 1 b and figure 2 c, d analysis shows that the product is a hexagonal hydroxyapatite solid nanostructure microsphe...

Embodiment 3

[0035] The preparation method of hydroxyapatite nanostructure microspheres in this embodiment is as follows:

[0036] Take 20mL of 0.4mol / L calcium chloride and 20mL of 0.24mol / L diammonium hydrogen phosphate solution and mix, the solution appears turbid, adjust the pH of the system to 3.5 with 0.5mol / L nitric acid, and the solution becomes clear. (Urea): n(Ca 2+ )=10:1, n(disodium edetate):n(Ca 2+ )=1:25 add urea and disodium edetate, the total volume of the solution after dissolution is 40mL, the concentration of calcium chloride is 0.2mol / L, the concentration of diammonium hydrogen phosphate is 0.12mol / L, and the solution is transferred to The 50mL autoclave adopts solvothermal synthesis reaction at 140°C for 3 hours to obtain hydroxyapatite nanostructure microspheres.

[0037] Depend on figure 1 c and figure 2 e, f analysis shows that the product is hexagonal hydroxyapatite solid nanostructure microspheres. composed of nanosheets. The specific surface area of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com