Method for modifying nano hydroxyapatite, nano hydroxyapatite/polylactic acid compound material and preparation method of nano hydroxyapatite/polylactic acid compound material

A nano-hydroxyapatite and composite material technology, applied in the field of composite materials, can solve the problems of high reaction temperature, reduced hydroxyapatite purity, high equipment and process requirements, achieve good dispersion performance, improve interface compatibility, The effect of short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

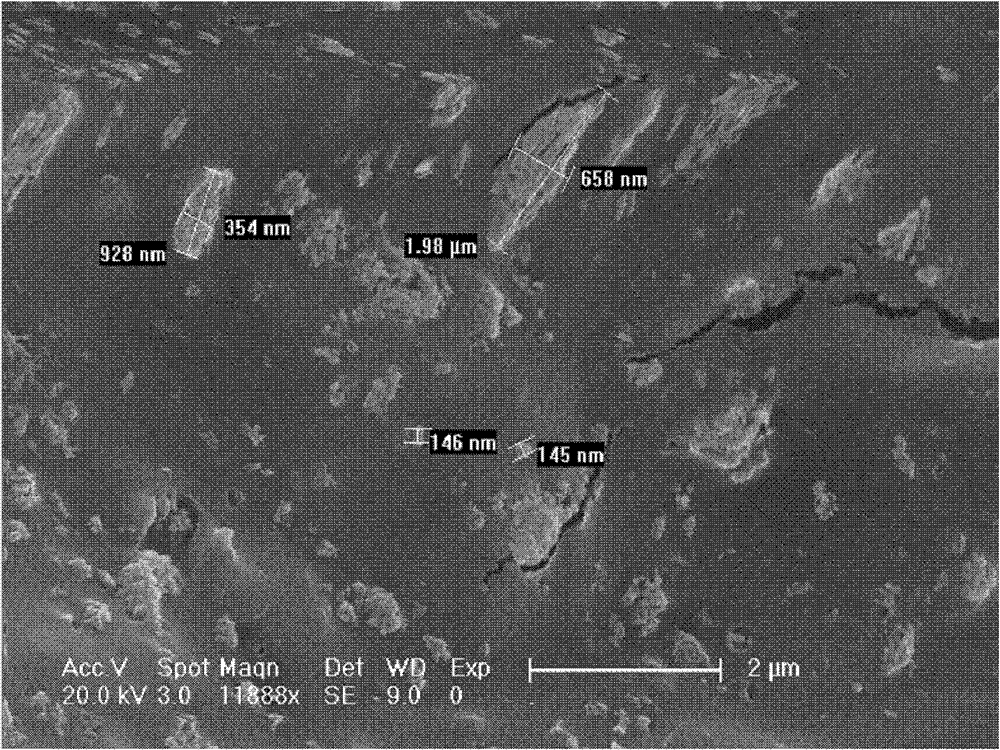

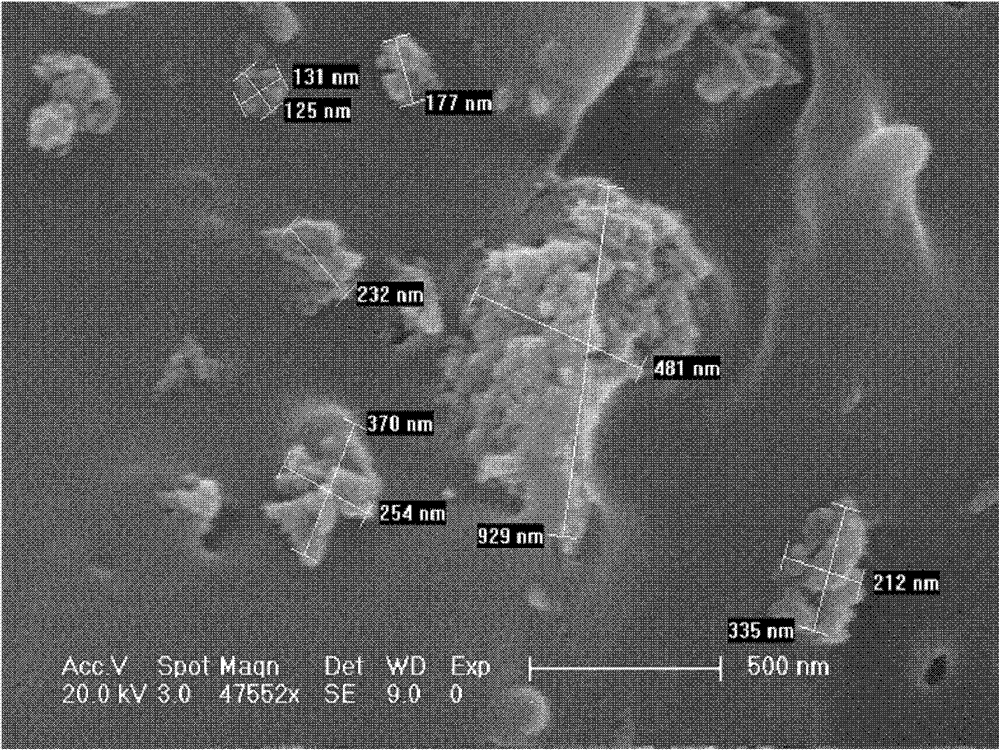

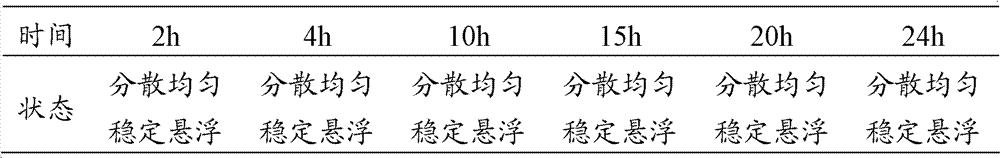

[0063] The modification of embodiment 1 nano-hydroxyapatite

[0064] 20g of oligomeric lactic acid with a number average molecular weight of 600 is heated and dissolved in 300mL of acetone to obtain a oligomeric lactic acid acetone solution; 75g of nano-hydroxyapatite hydrosol is added to the oligomeric lactic acid-acetone solution, and the nano-hydroxyapatite The mass of water in the hydrosol is 2.5 times the mass of nano-hydroxyapatite. After ultrasonic treatment for 40 minutes, add 300 mL of distilled water. After filtration, the obtained filtrate is dried under reduced pressure at 40°C for 72 hours to obtain nano-hydroxyapatite and oligomeric a mixture of lactic acids;

[0065] Dissolve the mixture of nano-hydroxyapatite and oligomeric lactic acid in 100 mL of chloroform, sonicate for 15 minutes, then centrifuge at high speed for 15 minutes, repeat the operation 3 times to remove excess oligomeric lactic acid, and dry under reduced pressure at 40°C for 72 hours to obtain o...

Embodiment 2

[0071] Modification of embodiment 2 nanometer hydroxyapatite

[0072] 20g of oligomeric lactic acid with a number average molecular weight of 2300 is heated and dissolved in 300mL of acetone to obtain a oligomeric lactic acid acetone solution; 75g of nano-hydroxyapatite hydrosol is added to the oligomeric lactic acid-acetone solution, and the nano-hydroxyapatite The mass of water in the hydrosol is 2.5 times the mass of nano-hydroxyapatite. After ultrasonic treatment for 40 minutes, 300 mL of distilled water is added, and after filtration, the obtained filtrate is dried under reduced pressure at 60°C for 72 hours to obtain nano-hydroxyapatite and oligomers. a mixture of lactic acids;

[0073] Dissolve the mixture of nano-hydroxyapatite and oligomeric lactic acid in 100 mL of chloroform, sonicate for 15 minutes, then centrifuge at high speed for 15 minutes, repeat the operation 3 times to remove excess oligomeric lactic acid, and dry under reduced pressure at 40°C for 72 hours ...

Embodiment 3

[0076] Modification of embodiment 3 nanometer hydroxyapatite

[0077] 20g of oligomeric lactic acid with a number average molecular weight of 4700 was heated and dissolved in 300mL of acetone to obtain a oligomeric lactic acid acetone solution; 75g of nano-hydroxyapatite hydrosol was added to the oligomeric lactic acid-acetone solution, and the nano-hydroxyapatite The mass of water in the hydrosol is 2.5 times that of nano-hydroxyapatite. After ultrasonic treatment for 40 minutes, add 300 mL of distilled water. After filtration, dry the obtained filtrate at 80°C for 72 hours under reduced pressure to obtain nano-hydroxyapatite and oligomers. a mixture of lactic acids;

[0078] Dissolve the mixture of nano-hydroxyapatite and oligomeric lactic acid in 100 mL of chloroform, sonicate for 15 minutes, then centrifuge at high speed for 15 minutes, repeat the operation 3 times to remove excess oligomeric lactic acid, and dry under reduced pressure at 40°C for 72 hours to obtain oligom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com