Equipment for producing printed spunlaced non-woven fabric

A non-woven fabric and equipment technology, applied in the field of spunlace non-woven fabric production equipment, can solve the problems that non-woven fabrics cannot be printed on both sides at the same time, double-sided pattern ghosting and dislocation, easy to shed hair and shavings, etc., to achieve durability The effect of washing fastness is improved, it is not easy to shed hair and chips, and the effect of avoiding erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1, the base fabric is a parallel-laid spunlace nonwoven with a ratio of 5:5 of viscose polyester as an example to illustrate, and the specification of the parallel-laid spunlace nonwoven is 50gsm.

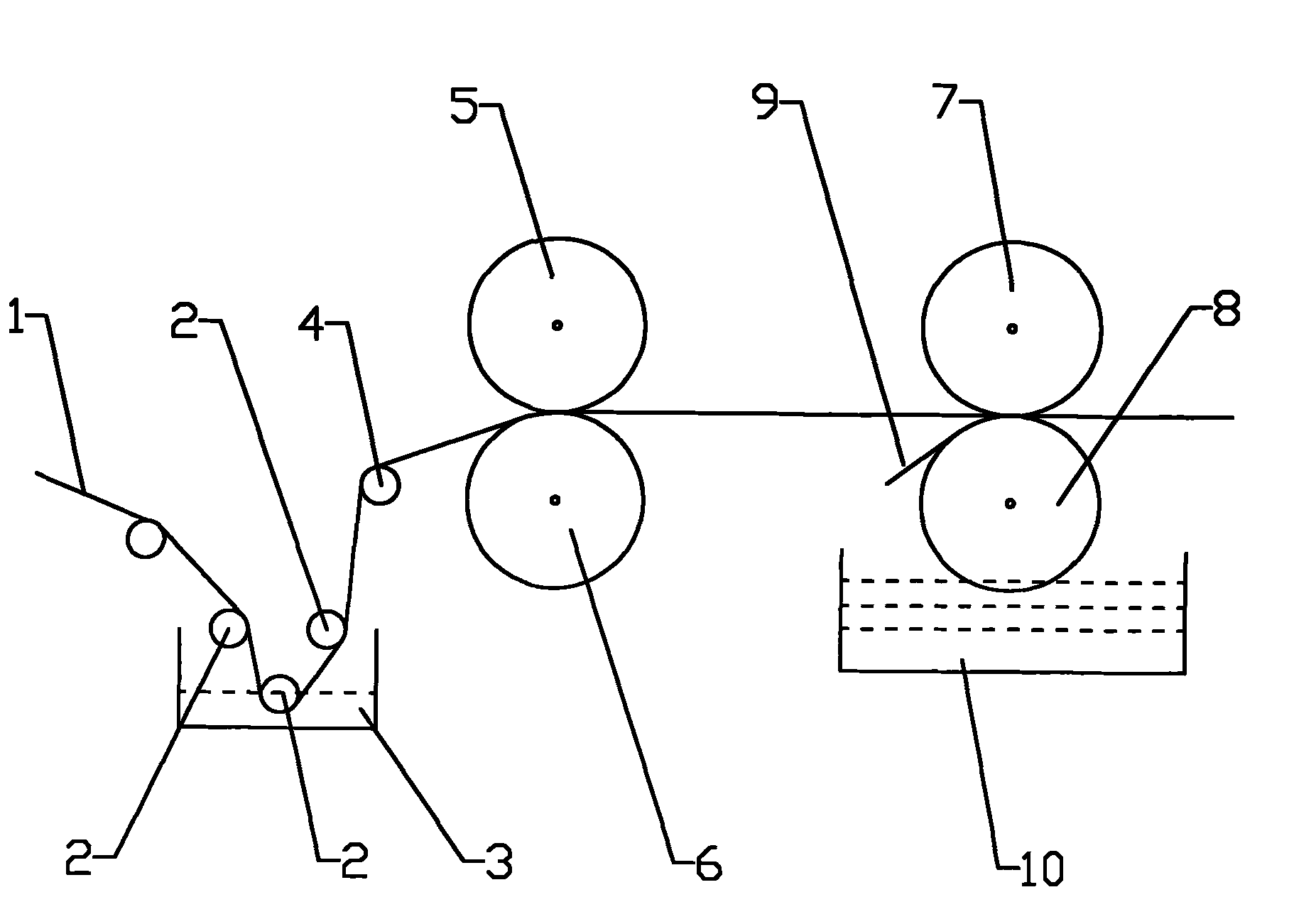

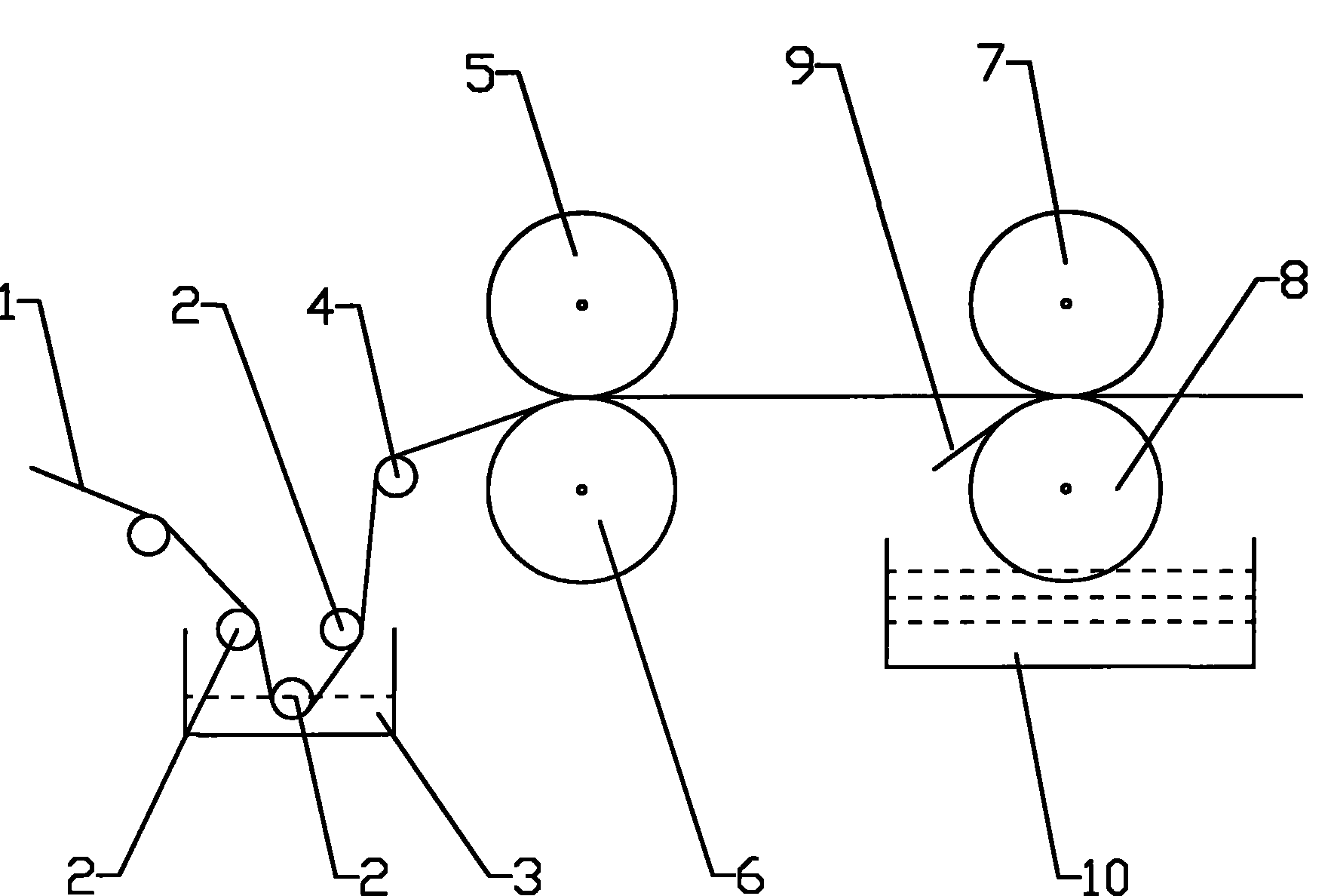

[0029] As shown in the figure, the equipment used for the production method of printing spunlace nonwoven fabrics includes a dipping device, a pressing device and a printing device. The dipping device is a dipping tank 3 and three guide rollers 2. The dipping device includes A dip tank 3 and three guide rollers 2, the dip tank 3 is a tank-shaped container, the three guide rollers 2 are arranged in the dip tank 3, the dip tank 3 contains a slurry solution, and one of the guide rollers 2 Immerse into the slurry to increase the residence time of the non-woven fabric in the slurry tank 3 to ensure that the slurry can evenly penetrate the spunlace non-woven fabric. The slurry includes a binder and a defoamer, and the solvent is softened water. The foaming agent mainly rem...

Embodiment 2

[0043]Example 2, the base cloth is a parallel-laid spunlace cloth of viscose fiber, the specification is 45gsm, the concentration of the adhesive in the slurry in the immersion tank 3 is 8%, the concentration of the defoamer is 0.4%, the above The pressure between the squeeze roller 5 and the lower squeeze roller 6 is 0.5Mpa, the concentration of the adhesive in the paste in the printing roller 8 is 10%, the concentration of the color paste is 0.8%, and the concentration of the thickener is 5% , the concentration of the defoaming agent is 0.4%, the pressure between the rubber roller 7 and the printing roller 8 is 0.6Mpa, and in the drying process, the spunlace nonwoven fabric after printing the pattern is heated to a temperature of 80 ° C, and the duration is 30-60S, then heat up to 160℃, the duration is 30-60S, and then dry with a rotary screen at a temperature of 130℃, the production speed is 25m / min, and then the finished printing spunlace is obtained through the testing pro...

Embodiment 3

[0048] Example 3, the base cloth is a parallel-laid spunlace cloth with polyester fibers, the specification is 50gsm, the concentration of the binder in the slurry in the immersion tank 3 is 9.5%, the concentration of the defoamer is 0.5%, and the upper extrusion The pressure between the pressing roller 5 and the lower pressing roller 6 is 0.5Mpa, the concentration of the binder in the paste in the printing roller 8 is 10%, the concentration of the color paste is 0.8%, and the concentration of the thickener is 5%. The concentration of the defoaming agent is 0.4%, the pressure between the rubber roller 7 and the printing roller 8 is 0.6Mpa, and in the drying process, the spunlace nonwoven fabric after printing the pattern is heated to a temperature of 80 ° C, and the duration is 30 -60S, then heat up to 160℃, the duration is 30-60S, and then dry with a rotary screen at a temperature of 130℃, the production speed is 20m / min, and then the finished printing spunlace non-woven fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com