Gas molten pool coupling active welding method

A welding method and gas technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems affecting the stability of welding process and welding production efficiency, increase equipment investment cost, increase heat input, etc. Automate welding production, improve welding efficiency, and increase the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

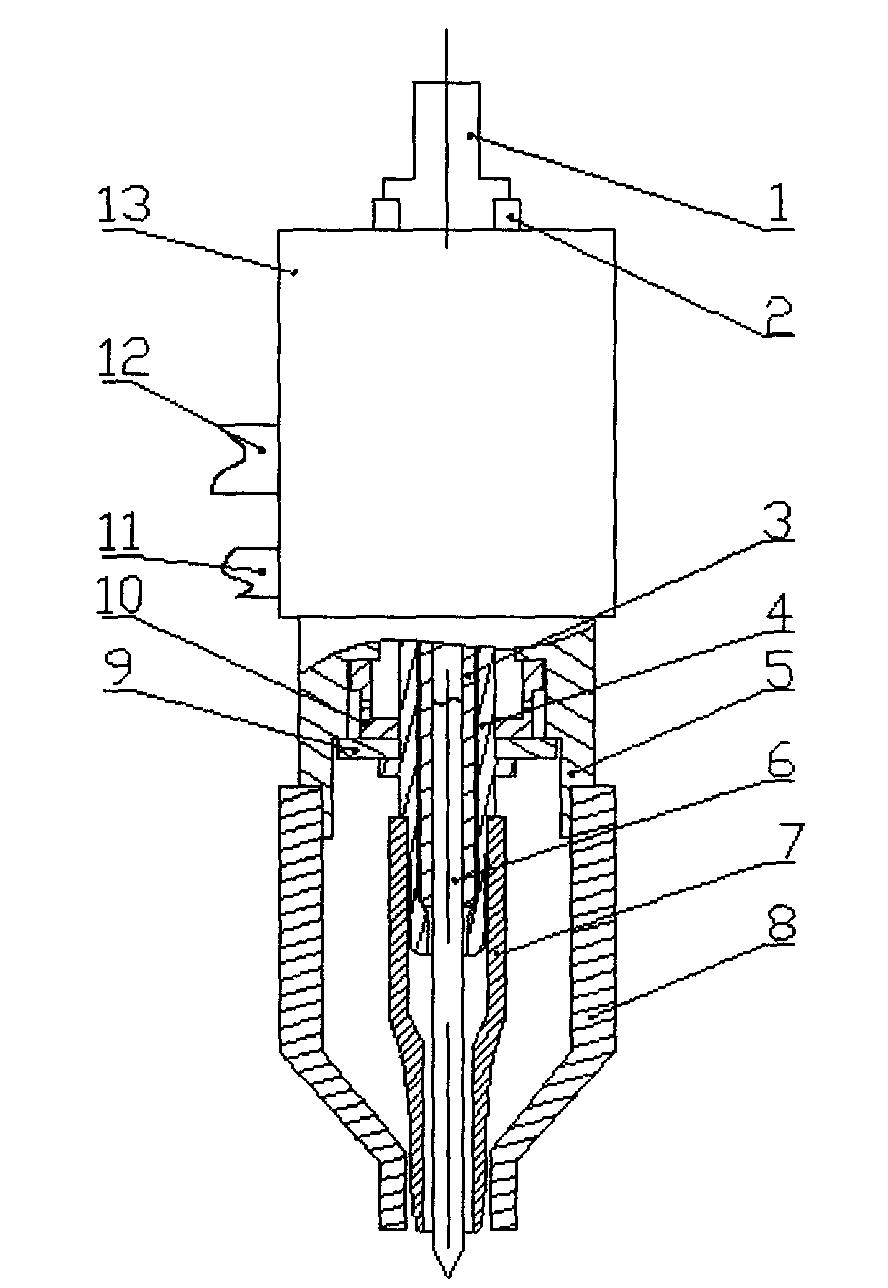

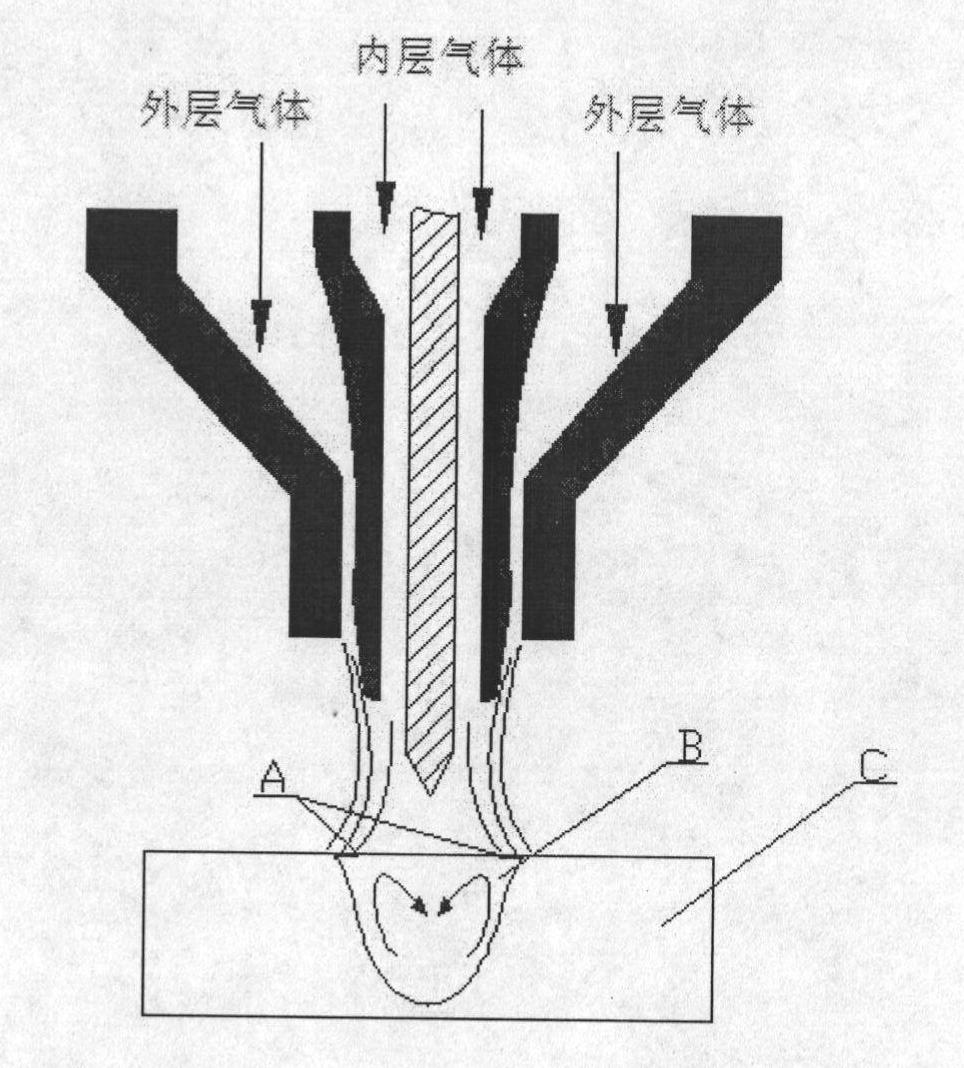

Method used

Image

Examples

Embodiment 1

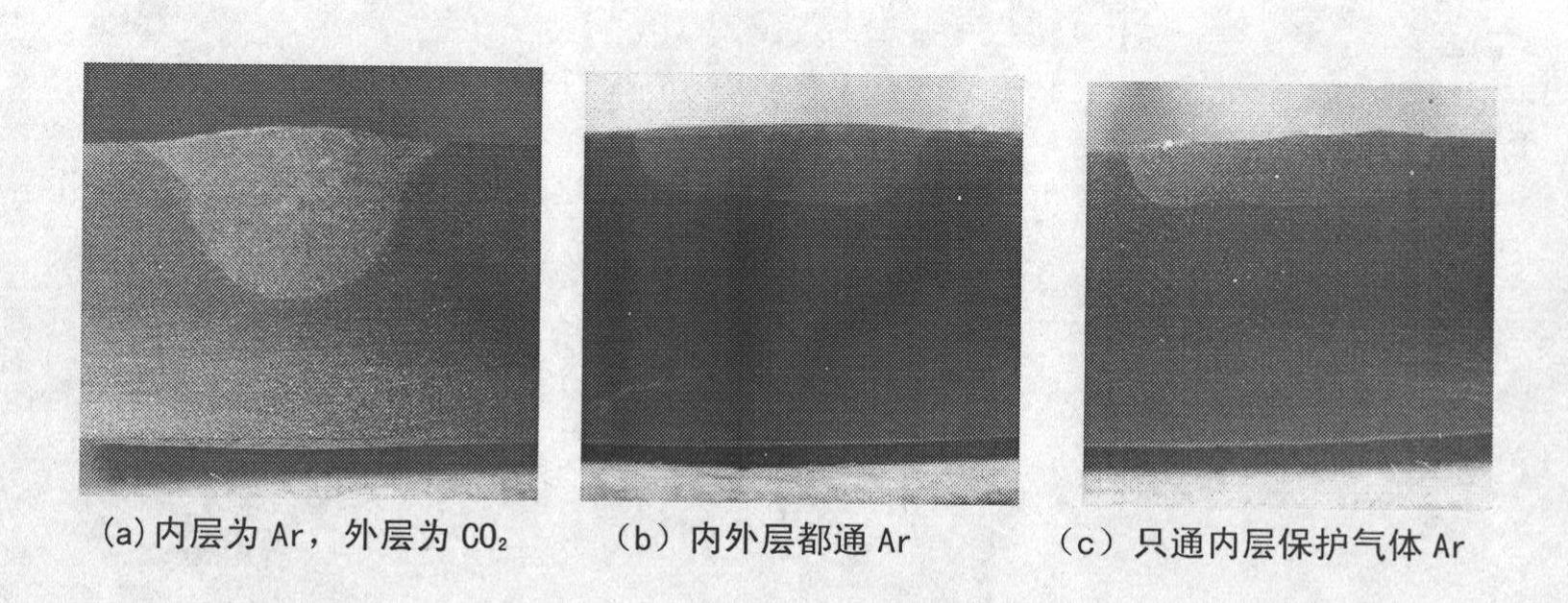

[0026] In this embodiment, the inner layer gas is Ar gas, the gas flow rate is 4L / min, and the outer layer gas is a single CO 2 Or Ar, the gas flow is 8L / min, the welding current is 160A, the welding speed is 120mm / min, the tungsten electrode extension length is 2mm, and the arc length is 2mm.

[0027] image 3 a is the outer gas is CO 2 , the weld morphology after coupling welding between gas and molten pool, in which the inner layer gas is Ar gas; image 3 b is the penetration depth of the weld when both the inner and outer layers are filled with Ar gas; image 3 c is the penetration depth of the weld when the inner layer only passes through the gas Ar, and there is no outer layer gas. Will image 3 a and image 3 b In comparison, it is confirmed that the outer layer gas containing active element O can couple with the molten pool metal and significantly increase the weld penetration; image 3 b and image 3 The penetration depth of c is almost the same, indicating tha...

Embodiment 2

[0029] In this embodiment, the inner layer gas is Ar gas, the gas flow rate is 4L / min, and the outer layer gas is N 2 and CO 2 The mixed gas, the gas flow rate is 10L / min, the welding current is 160A, the welding speed is 80mm / min, the tungsten electrode extension length is 3mm, and the arc length is 3mm.

[0030] Such as Figure 4 as shown, Figure 4 The outer gas in a is pure CO 2 , the weld penetration depth is 4.98mm, the fusion width is 9.64mm, and the aspect ratio is 0.52; Figure 4 The outer gas in b has 10% N added 2 , the weld penetration depth is 4.61mm, the fusion width is 8.42mm, and the aspect ratio is 0.55; Figure 4 The outer gas in c has 30% N added 2 , the weld penetration depth is 7.19mm, the fusion width is 9.31mm, and the aspect ratio is 0.77; Figure 4 The outer gas in d has 50% N added 2 , The weld penetration depth is 7.17mm, the fusion width is 8.66mm, and the aspect ratio is 0.83. In the welding process, after adding a certain proportion of O ...

Embodiment 4

[0032] In this embodiment, the inner layer gas is Ar gas, the gas flow rate is 4L / min, and the outer layer gas is a single N 2 or CO 2 , the gas flow rate is 10L / min, the welding current is 160A, the welding speed is 80mm / min, the tungsten electrode extension length is 3mm, and the arc length is 3mm.

[0033] Such as Figure 6 As shown, the impact energy of the weld metal and the base metal under different conditions were compared, and the comparison 1 and 2 confirmed that when a certain proportion of O was introduced, the impact toughness of the weld metal decreased significantly compared with the base metal; The impact energy of 2 and 3 is close, obviously higher than 1, indicating that adding a certain proportion of N element can improve the impact toughness of the weld.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com