Comprehensive process for simultaneously preparing series colorful purple sweet potato wine and purple sweet potato pigment

A purple sweet potato pigment and comprehensive process technology, applied in the comprehensive process field of simultaneously preparing a series of colored purple sweet potato wine and purple sweet potato pigment, can solve the problems of energy consumption, resource waste, etc., reduce energy consumption, improve production efficiency, and product purity Effect with high nutritional content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

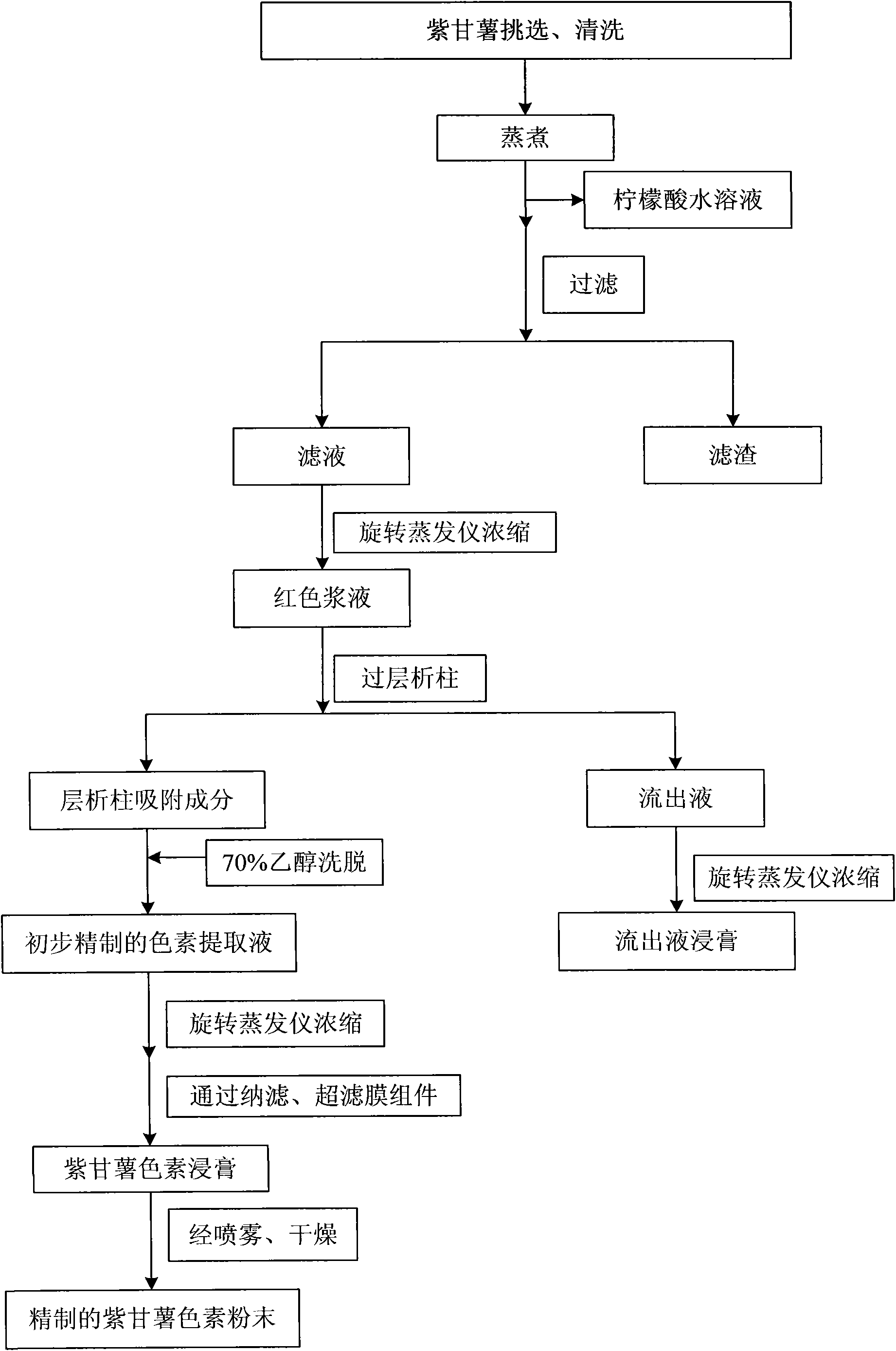

[0044] Combined with the accompanying drawings, select fresh and non-rotten purple sweet potatoes, put them in the rinsing tank for cleaning, then cook the cleaned purple sweet potatoes at normal pressure and 100°C, cool them to 45°C after steaming, and then place them in a quality The percentage is 3% citric acid aqueous solution to carry out crude extraction, the weight ratio of material to liquid is 1:5, acid adjusts pH to 2, filters, obtains filtrate and filter residue; Concentrates filtrate with rotary evaporator, obtains red slurry, will obtain The red slurry passes through the chromatography column equipped with AB-8 macroporous adsorption resin, the pigment is adsorbed on the resin, and macromolecular substances such as sugars flow out of the column to collect the effluent, which is then concentrated by a rotary evaporator to obtain the effluent extract; then use 70% acidic ethanol solution (the volume ratio of hydrochloric acid and ethanol is 3:7) to elute the pigment ...

Embodiment 2

[0049] Combined with the accompanying drawings, select fresh and non-rotten purple sweet potatoes, put them in the rinsing tank for cleaning, then cook the cleaned purple sweet potatoes at normal pressure and 100°C, cool them to 50°C after steaming, and then place them in the quality The percentage is 3% citric acid aqueous solution to carry out crude extraction, the weight ratio of material to liquid is 1:5, acid adjusts pH to 3, filters, obtains filtrate and filter residue; Concentrates filtrate with rotary evaporator, obtains red slurry, will obtain The red slurry passes through the chromatography column equipped with AB-8 macroporous adsorption resin, the pigment is adsorbed on the resin, and macromolecular substances such as sugars flow out of the column to collect the effluent, which is then concentrated by a rotary evaporator to obtain the effluent extract; then use 70% acidic ethanol solution (the volume ratio of hydrochloric acid and ethanol is 3:7) to elute the pigmen...

Embodiment 3

[0054] Select 100ml of pure grain white wine with an alcohol content of 52 degrees, add 20-30mg of refined purple sweet potato pigment to it, stir and dissolve to obtain purple sweet potato wine, the color of the wine is purple, and the content of anthocyanin in the liquor is 200-300mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com