Preparation method of grapheme three-dimensional entity

A technology of three-dimensional solids and graphene, which is applied in the field of preparation of three-dimensional graphene solids, can solve problems such as low density and rough solid surface, and achieve the effects of convenient operation, improved mechanical properties and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: The first step, weigh 55mg of graphene oxide sheets, place in a beaker, add 33ml of deionized water in the beaker, then carry out ultrasonic dispersion (40KHz, 15min), make the solution without obvious particles, then add ammonia water Make the pH of the solution 10;

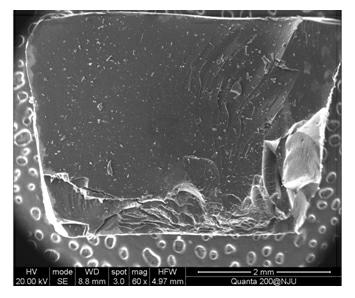

[0019] In the second step, pour the solution in the beaker into the inner cup of the hydrothermal reaction kettle (volume 50ml), tighten the lid of the outer cup, put it upright in the drying oven, set the heating rate to 50°C / min, and the reaction temperature to 180°C. The reaction time is 15 hours, and it is naturally cooled after the reaction is completed. Scanning electron micrographs of the three-dimensional solids of graphene as figure 2 As shown, it can be observed that the surface is smooth;

[0020] The third step is to dry the prepared entity at 45°C and normal pressure for 15h; the scanning electron micrograph of the dried product is as follows: image 3 with Figure 4 shown....

Embodiment 2

[0024] Embodiment 2: The preparation method is basically the same as in Example 1, the difference is: the dispersion of graphene oxide is achieved by stirring, and less ammonia water is added to make the solution pH=8, Figure 5 It is a scanning electron micrograph of the obtained three-dimensional graphene solid, and it can be seen that the surface of the obtained solid is also very smooth. Table 2 is a comparison of the relative properties of the graphene three-dimensional entity and the three-dimensional entity obtained without ammonia water.

[0025] sample

[0026] Table 2

Embodiment 3

[0027] Embodiment 3: The preparation method is basically the same as that of Embodiment 1, the difference is: the heating rate of the drying oven is set to 5°C / min, and the following figure 2 Similar results are shown, see Table 3 for performance comparison.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com