Chip type high polymer electrostatic discharge protecting element and manufacturing method thereof

A technology for electrostatic discharge protection and component manufacturing, which is applied in the field of patch-type polymer ESD protection components and its manufacturing, can solve the problems of complex lead-out methods for connecting internal and external electrodes, signal attenuation and distortion, and small effective capacitance, etc., to achieve Meets ESD protection requirements, facilitates electrode graphic design, and has good connection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

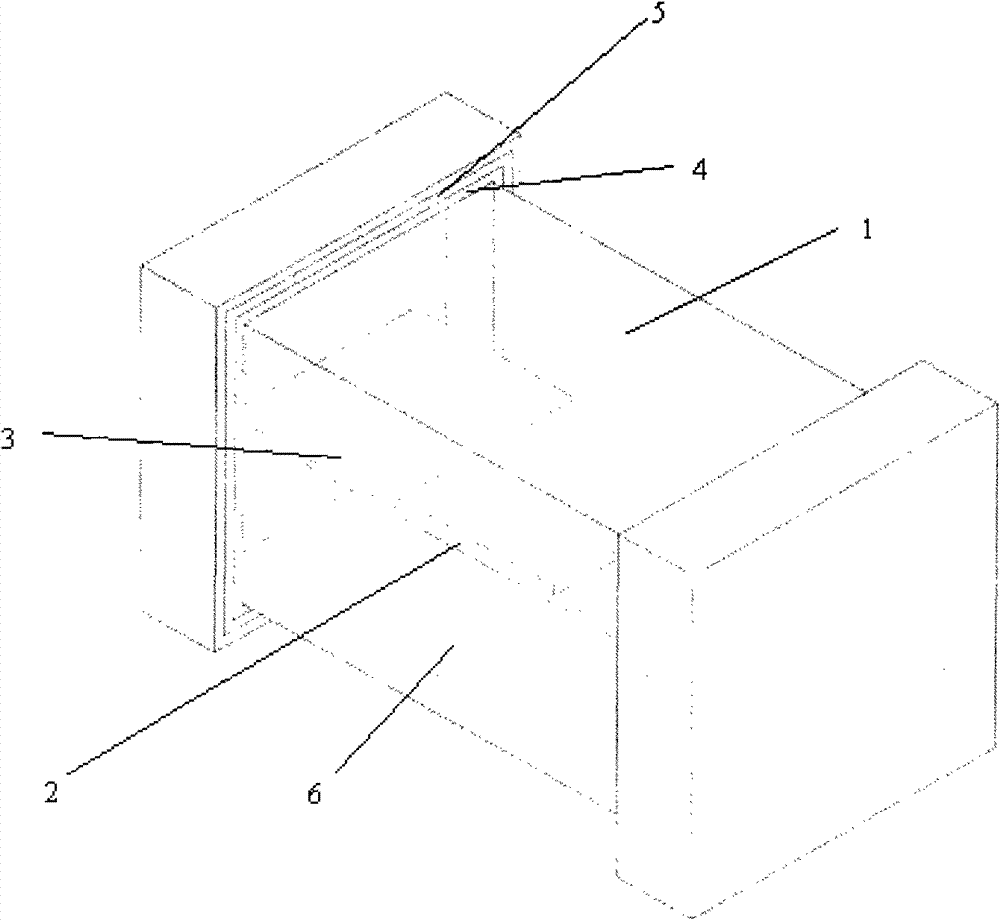

[0056] a kind of like Figure 1~3 The chip-type polymer electrostatic discharge protection component shown includes an upper substrate 1 , a lower substrate 6 , a core material 2 , two inner electrodes 3 , two terminal electrodes 4 and two electroplating layers 5 . The upper substrate 1, the lower substrate 6, and the core material 2 all belong to high molecular polymers, and all include a curing agent.

[0057] The two internal electrodes 3 are two internal electrodes opposing in the longitudinal direction, and the core material 2 is a core material filling a gap between the two internal electrodes 3 opposing in the longitudinal direction. The upper substrate 1 is an epoxy resin board, and the lower substrate 6 is an alumina ceramic board.

[0058] The core material 2 is a composite material, and the components and mass percentages of the core material slurry are as follows:

[0059] Epoxy resin 35.0%;

[0060] Silver powder 25.0%;

[0062] ...

specific Embodiment approach 2

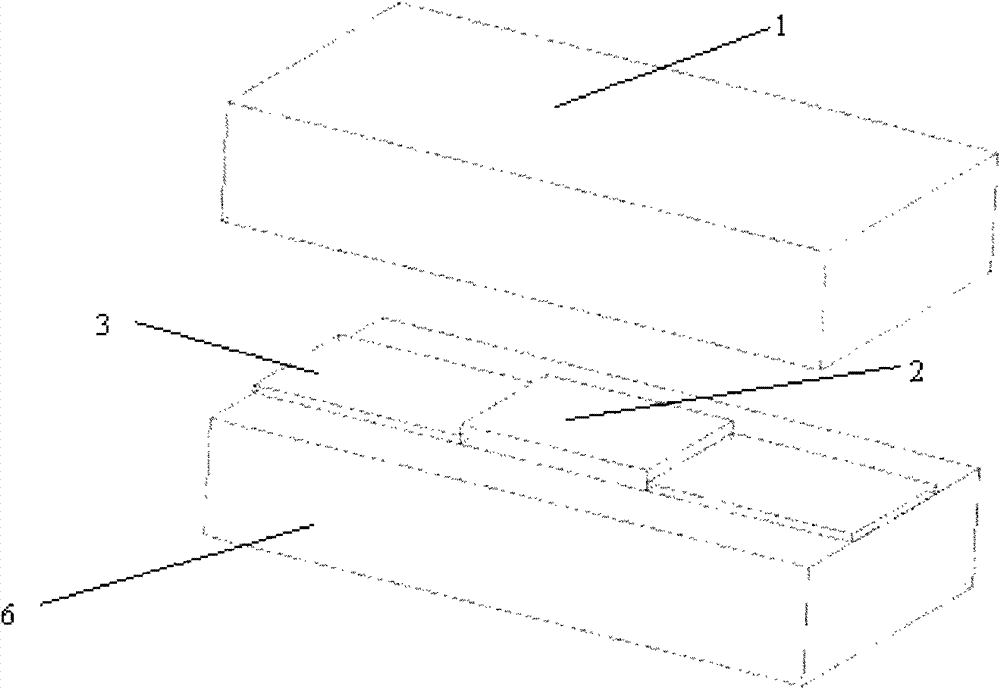

[0084] a kind of like Figure 4 The chip-type polymer electrostatic discharge protection component shown includes an upper substrate 1 , a lower substrate 6 , a core material 2 , two inner electrodes 3 , two terminal electrodes 4 and two plating layers 5 .

[0085] The composition and structure of the device is basically the same as that of Embodiment 1, the difference is:

[0086] The two internal electrodes 3 are two internal electrodes that intersect each other in the longitudinal direction, and the core material 2 is a core material that fills the gap between the two intersecting internal electrodes in the longitudinal direction. The lower substrate 1 and the lower substrate 6 are silicone resin plates.

[0087] Its manufacturing method is basically the same as specific embodiment one, and its difference is:

[0088] First prepare an internal electrode 3 , then prepare the core material 2 , and then prepare another internal electrode 3 .

[0089] The core material 2 is ...

specific Embodiment approach 3

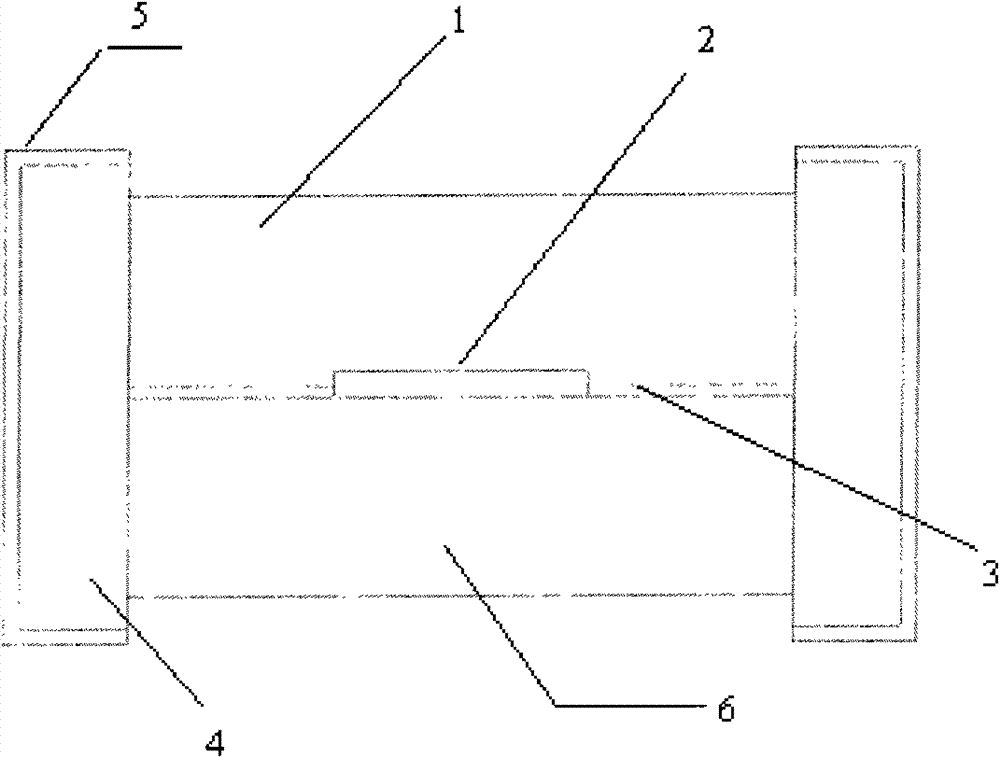

[0096] a kind of like Figure 5 , 6 The chip-type polymer electrostatic discharge protection component shown includes an upper substrate 1 , a lower substrate 6 , a core material 2 , two inner electrodes 3 , two terminal electrodes 4 and two plating layers 5 .

[0097] The composition and structure of the device is basically the same as that of Embodiment 1, the difference is:

[0098] The core material 2 is a core material that fills a through hole in the gap between two inner electrodes opposite in the length direction. The upper substrate 1 is an epoxy resin plate, and the lower substrate 6 is a glass-ceramic plate.

[0099] Its manufacturing method is basically the same as specific embodiment one, and its difference is:

[0100] Using a dicing and cutting machine, the glass-ceramic plate is cut into the lower substrate 6 according to the designed shape and size, and holes are opened on the lower substrate 6, and then the inner electrode 3 is prepared. When the core mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com