Solid fuel gasification and combustion device and boiler

A solid fuel and combustion equipment technology, applied in the direction of solid heating fuel, combustion method, lighting and heating equipment, etc., can solve the problems of easy generation of soot and dust, atmospheric environment pollution by soot and dust, insufficient combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

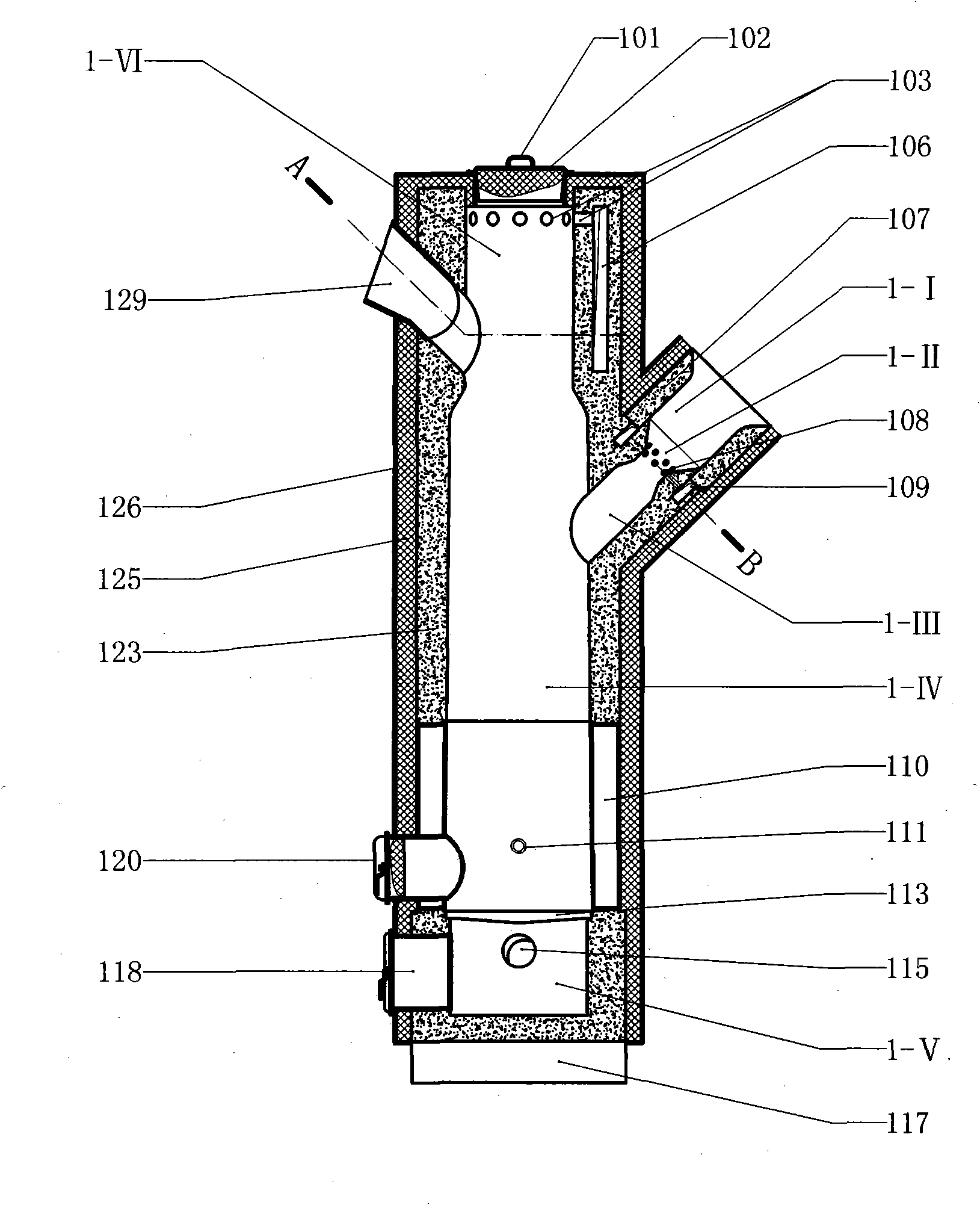

[0028] Example 1 figure 1Shown is a gasification combustion equipment using solid fuel, wherein the gasification furnace (1-IV) is formed by the inner space of the vertical rotary furnace wall, and the rotary furnace wall includes a refractory layer a (123) and water Cover (110), refractory layer a (123) is on the water jacket (110), and the outer layer of refractory layer a (123) and water jacket (110) is insulation layer a (125), and insulation layer a (125) The outer layer is shell a (126); there is an air passage (1-VI) above the gasification furnace (1-IV), and the furnace wall of the air passage (1-VI) is the wall of the gasification furnace (1-IV). In the extension section, air holes a (103) are set on the furnace wall of the air passage (1-VI). The air chamber a (106), the air hole a (103) is connected to the annular air chamber a (106), and the annular air chamber a (106) has an air outlet port a (130) to connect; between the air passage (1-VI) and There is a feed / a...

Embodiment 2

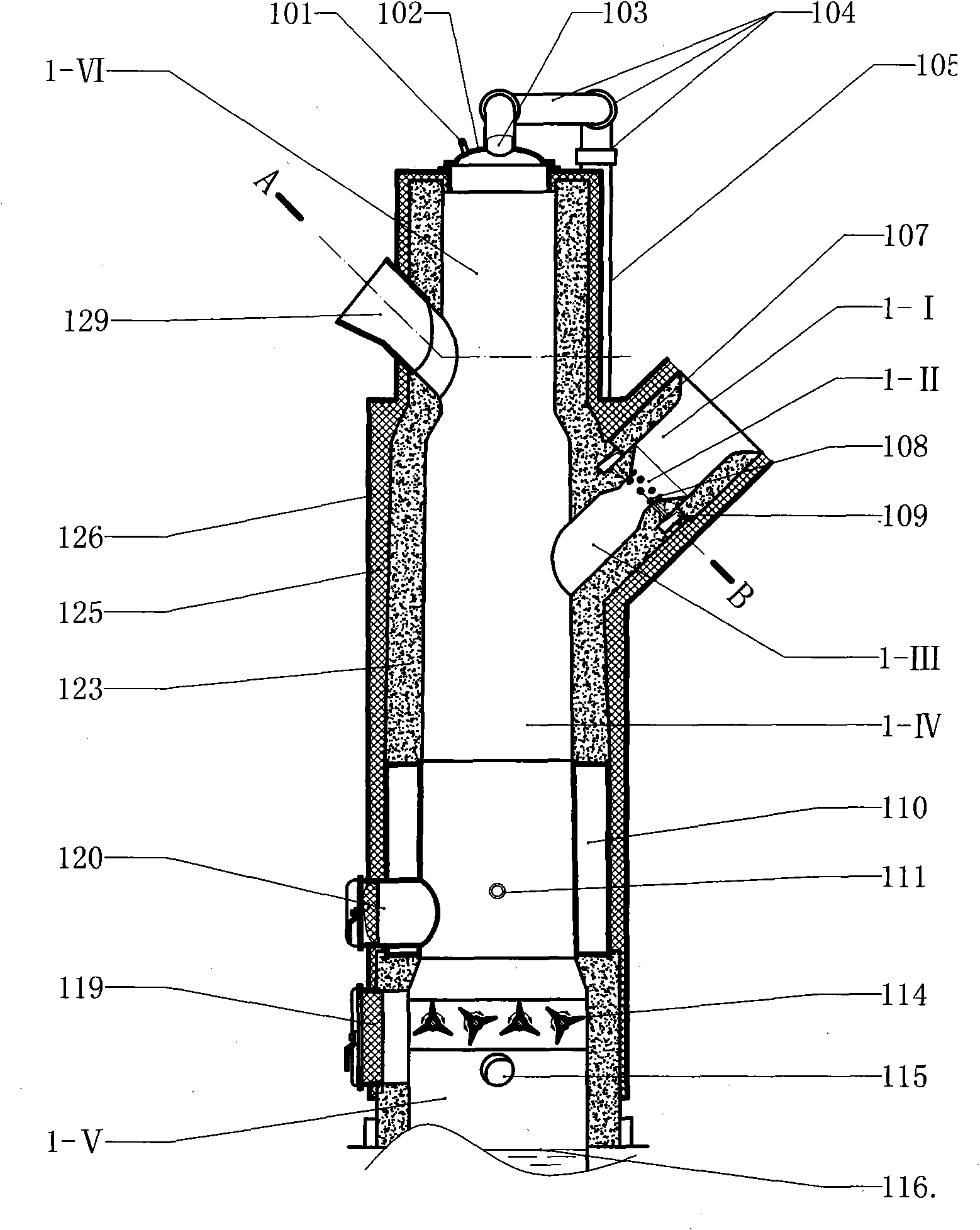

[0029] Example 2 figure 2 In the shown embodiment, the grate (113) in the first embodiment is replaced by a slag breaker (114), and the slag breaker (114) is made up of a rotating shaft and a crushing knife, wherein the crushing knife is in the form of a trident, and the fork It is a pyramid structure, and there are multiple crushing knives on each rotating shaft, and the rotating shaft is manually shaken or mechanically rotated by a motor-reduction mode; the air hole a (103) changes the stove top cover (102) in the air passage (1-VI). ), the air hole a (103) is connected to the air pipe (105) through the universal joint assembly (104), and the air pipe (105) is connected to the blower air inlet of the air supply system. The bottom of the air chamber (1-V) in this embodiment is a water seal (116), and the slag removal is a mechanical slag removal method. out.

Embodiment 3

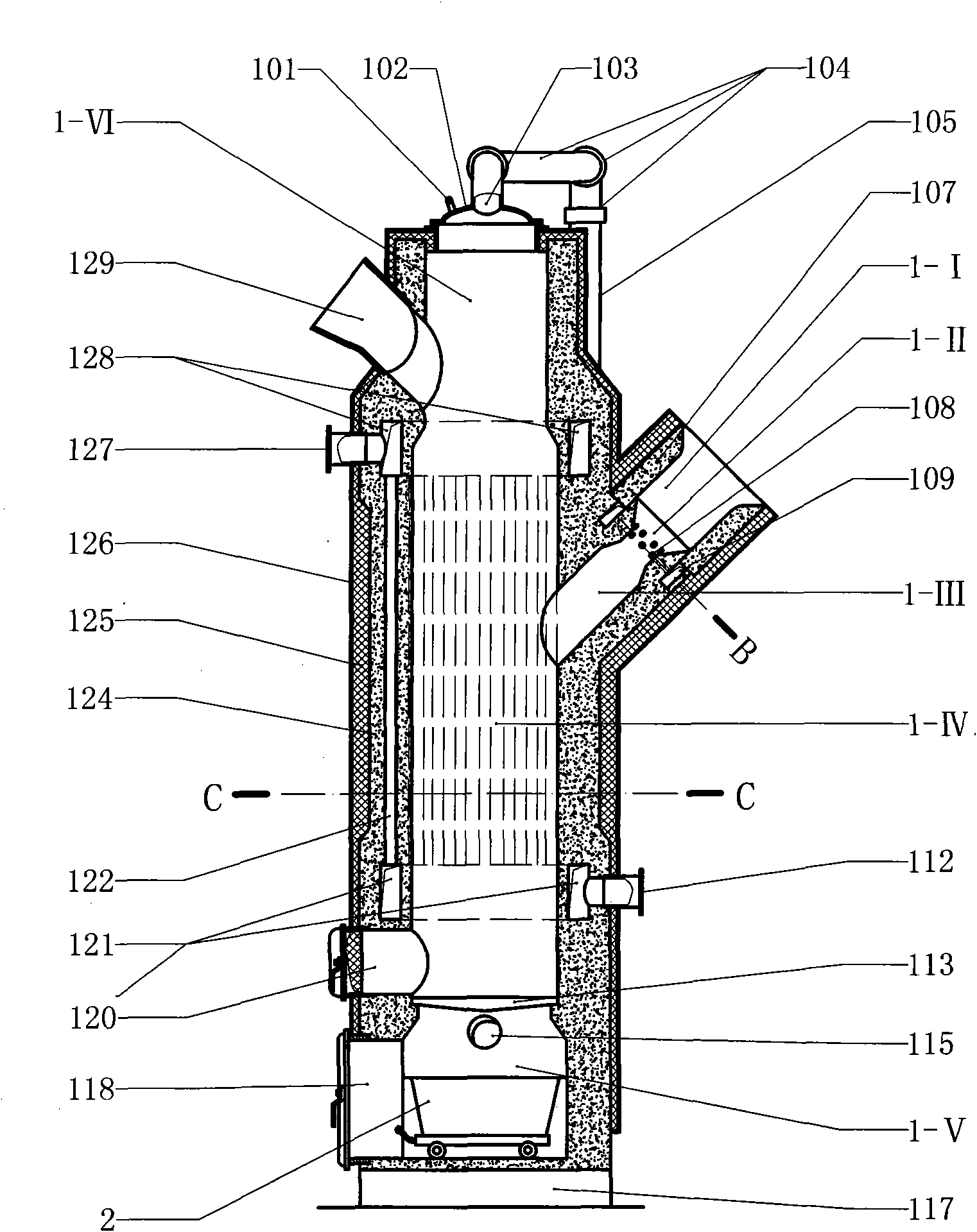

[0030] Example 3 image 3 In the shown embodiment, the refractory furnace wall (124) is used to replace the refractory layer a (123) and the water jacket (110) in the first embodiment or the second embodiment, and the refractory furnace wall (124) is a cylindrical structure, In the body of wall of the refractory furnace wall (124), there are annular air chamber b (128), pipe cavity (122) and annular air chamber c (121), annular air chamber b (128) is on the top, annular air chamber c (121 ) in the lower part, the pipe cavity (122) is connected between the annular air chamber b (128) and the annular air chamber c (121), and the pipe chamber (122) is distributed in a multi-pipe manner on the wall of the refractory furnace wall (124) In the body, the annular air chamber b (128) is connected to the air inlet port (127), and the annular air chamber c (121) is connected to the air outlet port b (112). When this embodiment is in operation, the combustion-supporting air enters the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com