Ultrasonic combined waste water treatment process and system of refuse leachate

A waste water treatment system and garbage permeate technology, which is applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. Huge and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

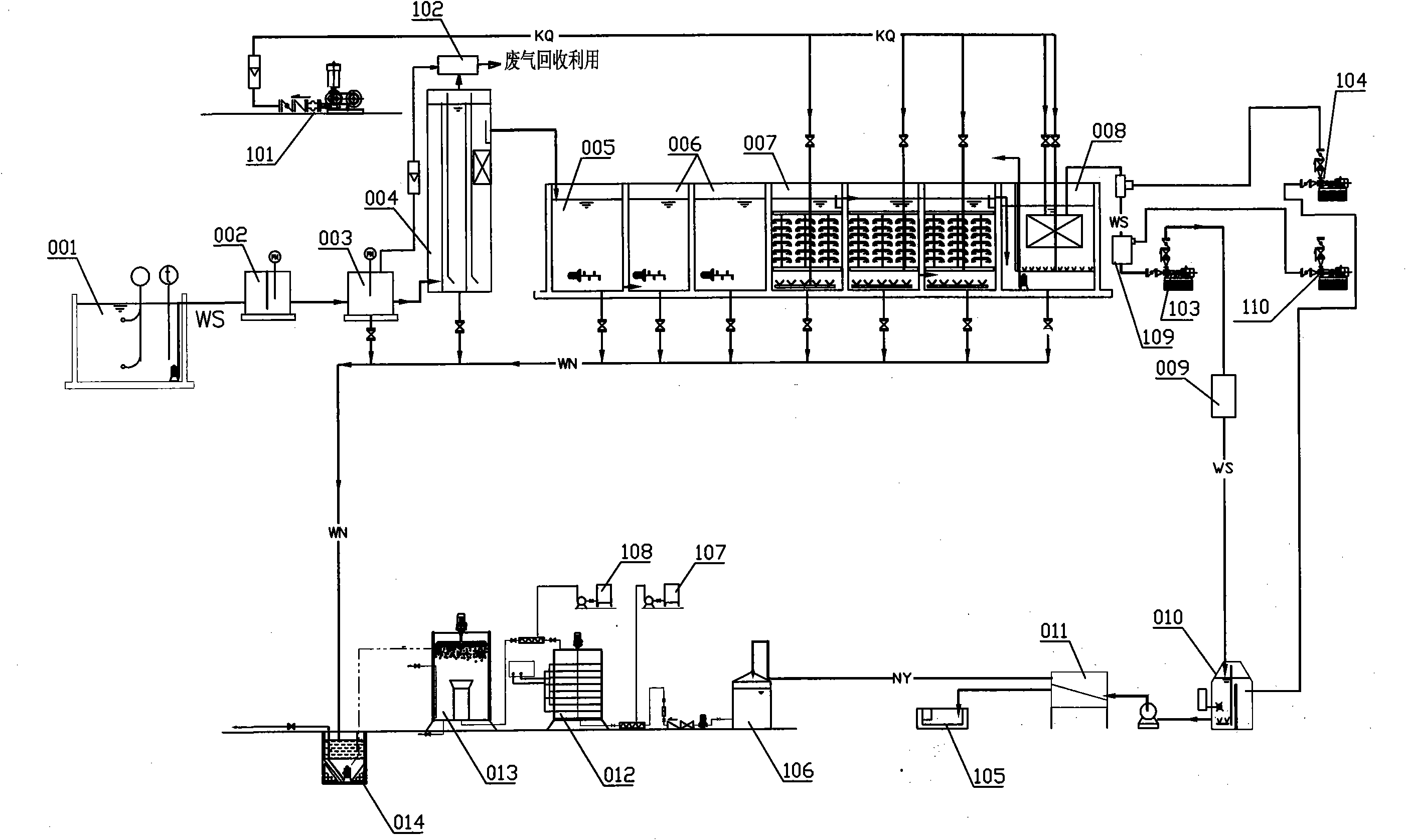

Image

Examples

Embodiment Construction

[0046] The preferred embodiment of the garbage permeate ultrasonic combined wastewater treatment process of the present invention is that after the garbage permeate is processed through the process of "ultrasonic catalytic oxidation pretreatment - biochemical treatment - RO membrane reverse osmosis system filtration treatment", the RO membrane reverse The concentrated water discharged from the osmosis system is further treated. The process steps are as follows:

[0047] (a) The garbage permeate is removed from the large suspended solids through the grid channel and then enters the covered regulating tank, where most of the suspended solids, hair, and large gravel are intercepted and precipitated, the water quality and quantity are adjusted, and anaerobic and hydrolysis reactions occur.

[0048] (b) adjust the pH value of the solution treated in step (a) in the coagulation sedimentation tank, add composite coagulant LC1 and composite flocculant LC2 to precipitate inorganic diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com