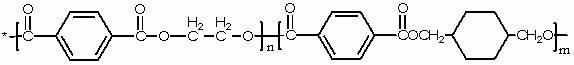

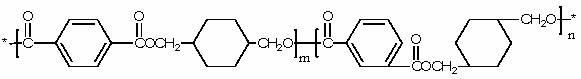

ABS (acrylonitrile butadiene styrene) /PET (polyethylene terephthalate) /copolyester ternary alloy and preparation method thereof

A ternary alloy and copolyester technology, applied in the field of ABS/PET/copolyester ternary alloy, can solve the problem of high material cost, achieve the effects of good compatibility, improved physical and mechanical properties, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Accurately weigh 70kg of ABS resin, 18kg of PET resin, 10kg of PCTG, 1kg of SMA, 0.2kg of 1010, 0.2kg of 168, and 0.6kg of EBS; fully mixed by a high-mixer, and a co-rotating twin-screw extruder is used for melt blending in one step The method (extrusion temperature: 170-250°C) is used to obtain the ternary alloy of the present invention. The material prepared in this embodiment is injection molded into a standard test strip according to a standard size using an injection molding machine. The physical properties after the test are (ISO standard): tensile strength 45MPa, IZOD notched impact strength 27kJ / m 2 , Bending strength 66MPa; Melting index 11g / 10min (220℃ / 10kg).

Embodiment 2

[0033] Accurately weigh 60kg of ABS resin, 23kg of PET resin, 15kg of PETG, 1kg of SMA, 0.2kg of 1010, 0.2kg of 168, 0.6kg of EBS; fully mixed by a high-mixer, using a co-rotating twin-screw extruder with one-step melt blending The method (extrusion temperature: 170-250°C) is used to obtain the ternary alloy of the present invention. The material prepared in this example is injection molded into a standard test strip according to the standard size by an injection molding machine. The physical properties after the test are (ISO standard): tensile strength 47MPa, IZOD notched impact strength 32kJ / m 2 , Flexural strength 675MPa; melt index 12g / 10min (220℃ / 10kg).

Embodiment 3

[0035] Accurately weigh 40kg of ABS resin, 33kg of PET resin, 25kg of PETG, 1kg of EGMA-g-PS, 0.2kg of 1010, 0.2kg of PS802, and 0.6kg of silicone oil; fully mixed by a high mixer, using a co-rotating twin screw extruder. The one-step extrusion method of melt blending (extrusion temperature: 170-250°C) can obtain the ternary alloy of the present invention. The material prepared in this example is injection molded into a standard sample with an injection molding machine according to a standard size. The physical properties after the test are (ISO standard): tensile strength 49MPa, IZOD notched impact strength 23kJ / m 2 , Flexural strength 72MPa; Melt index 14g / 10min (220℃ / 10kg).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com