Mold/non-mode combined pulling process and device

A combined drawing and process technology, used in metal drawing forming tools, metal wire drawing, manufacturing tools and other directions, can solve the problems of reducing drawing force, large deformation without die drawing and die drawing, etc. The effect of drawing force, shortening drawing pass, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

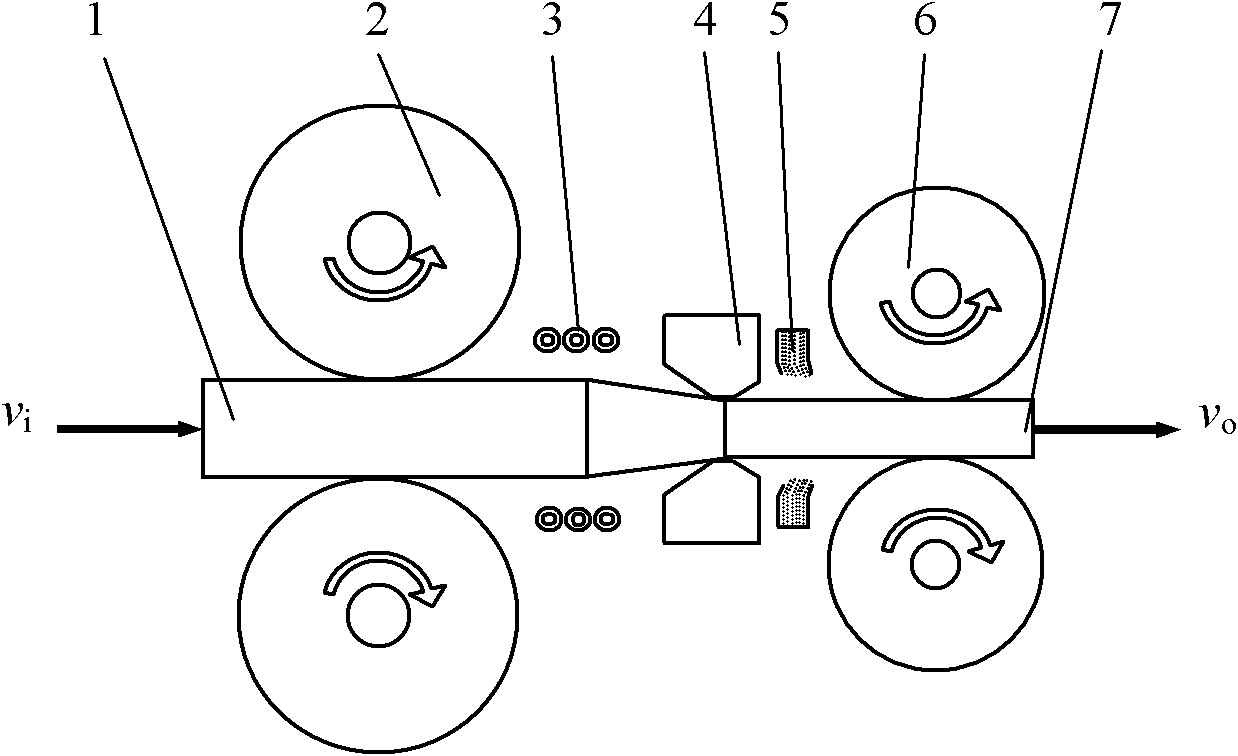

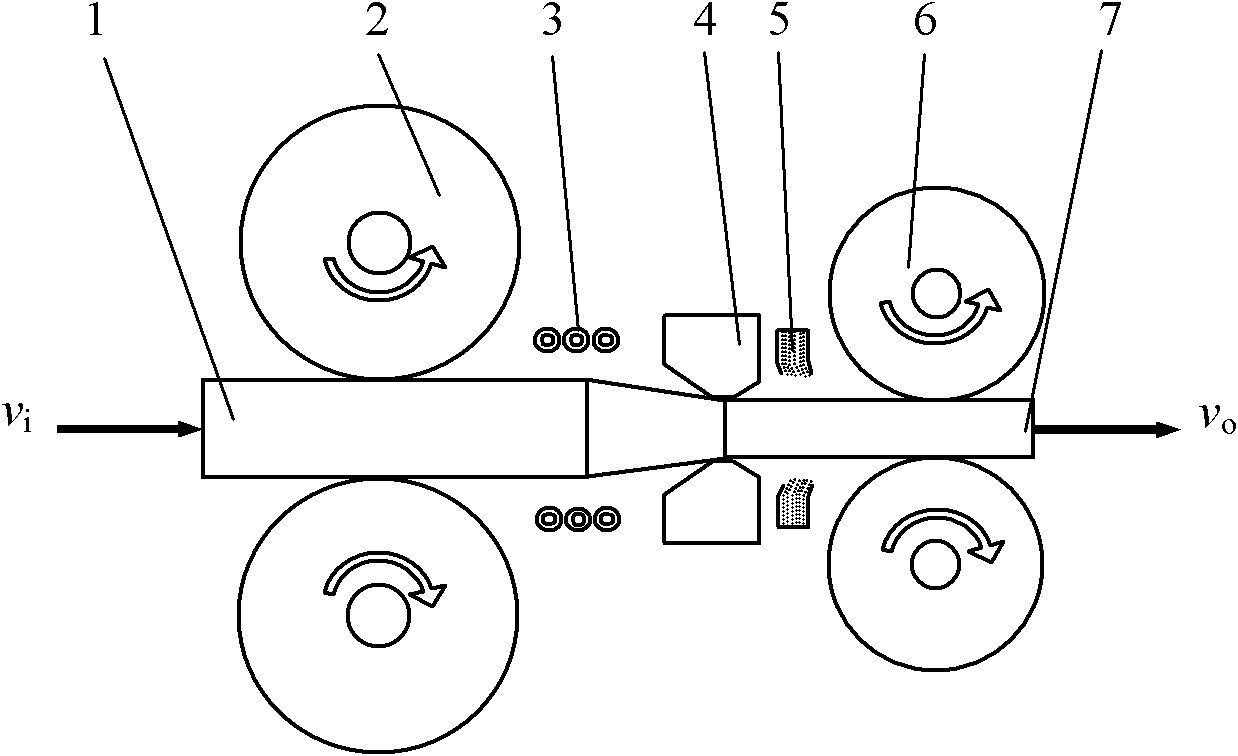

[0030] A nearly equiatomic ratio nickel-titanium shape memory alloy wire rod with a diameter of 6 mm was selected as the billet, which passed through the feeding mechanism (2), heater (3), drawing die (4), cooler (5) and The traction mechanism (6); then, turn on the heater (3) to heat it to 783K (0.50 times its melting point temperature Tm); start the feeding mechanism (2) and the traction mechanism (6) at the same time, at the drawing speed Vo Under the condition of the ratio Vo / Vi=2.2 to the feed speed Vi of the billet, the joint drawing with die (4) and the cooler (5) is used to complete the combined drawing with die / die; the diameter is 4 mm and the surface finish is good. , Near-equal atomic ratio nickel-titanium shape memory alloy wire with high dimensional accuracy.

Embodiment 2

[0032] Select 304 stainless steel wire rod with a diameter of 6 mm as the billet, pass through the feeding mechanism (2), heater (3), drawing die (4), cooler (5) and traction mechanism (6) in sequence after being sharpened; then , turn on the heater (3) to heat it to 1540K (0.90 times its melting point temperature Tm); start the feeding mechanism (2) and traction mechanism (6) at the same time, at the drawing speed Vo and the billet feeding speed Vi Under the condition of ratio Vo / Vi=2.8, through the action of drawing die (4) and cooler (5), combined drawing with die / die is completed; 304 stainless steel with a diameter of 3.6 mm, good surface finish and high dimensional accuracy is obtained wire.

Embodiment 3

[0034] Select the YL12 aluminum alloy wire rod with a diameter of 6 mm as the billet, and pass through the feeding mechanism (2), heater (3), drawing die (4), cooler (5) and traction mechanism (6) in sequence after tipping; Then, turn on the heater (3) to heat it to 745K (0.85 times its melting point temperature Tm); start the feeding mechanism (2) and traction mechanism (6) at the same time, at the drawing speed Vo and the billet feeding speed Vi Under the condition of the ratio Vo / Vi=2.3, through the drawing die (4) and cooler (5) to complete the joint drawing with die / die; obtain YL12 with a diameter of 4 mm, good surface finish and high dimensional accuracy Aluminum alloy wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com