A kind of drawing forming device and method of tin-bismuth alloy welding wire

A tin-bismuth alloy, stretching forming technology, applied in the direction of drawing dies, etc., can solve the problems of increased single-pass deformation, increased probability of instability, and inability to stretch, and achieves reduction of secondary deformation, increased deformation, Optimize the effect of reasonable distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

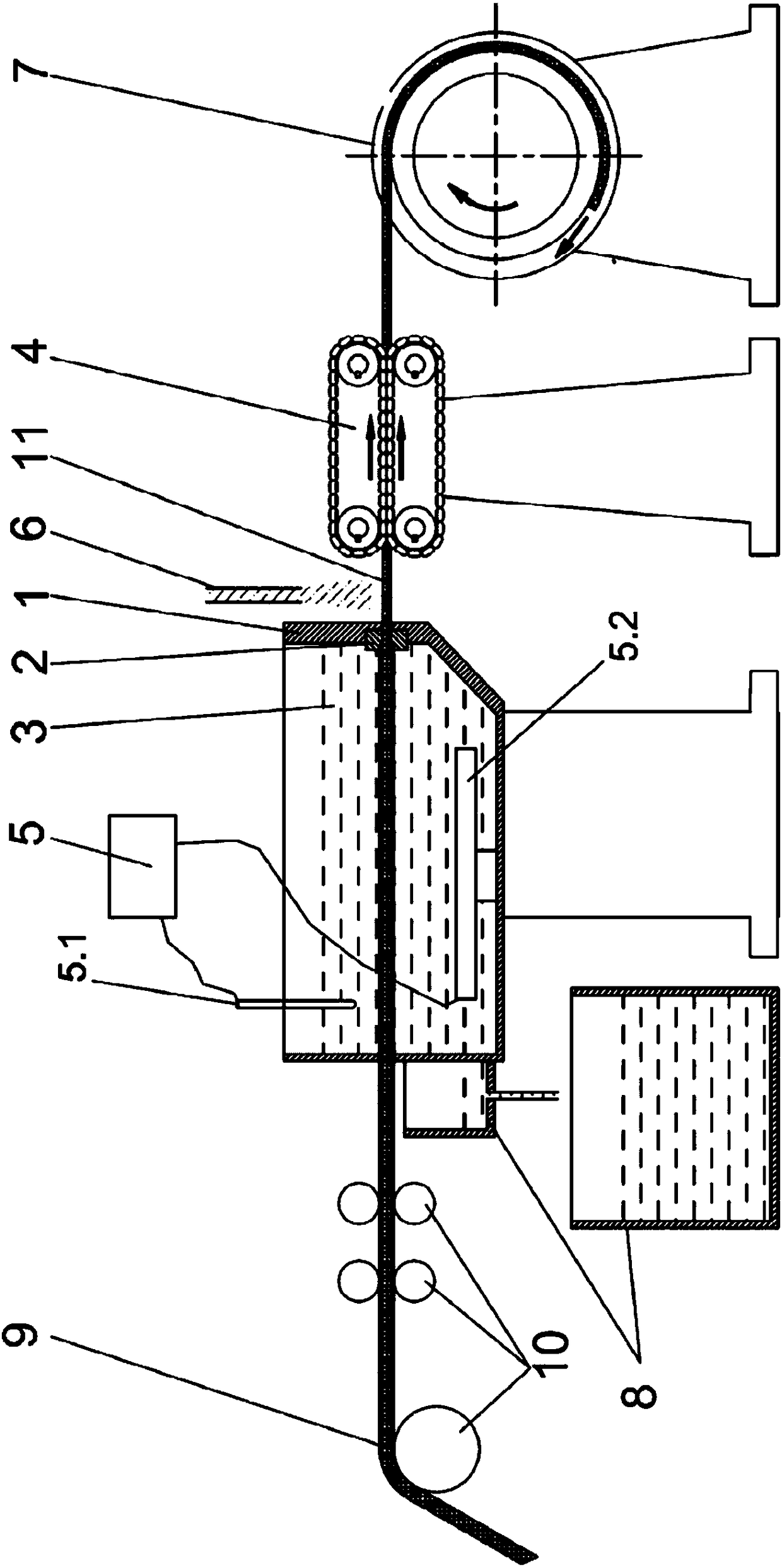

[0049] The stretch forming device of the present invention is mainly composed of a mold base 1, a mold 2, a stretching liquid 3, a drawing machine 4, a constant temperature heater 5, a cooler 6, a winder 7, and an overflow circulation device 8, and is used for preparing Sn-57wt%Bi alloy wire with a diameter of 2.0 mm.

[0050] At first, the drawing forming device of above-mentioned a kind of tin-bismuth alloy welding wire is installed, and the drawing die 2 that sizing is Φ 2.0mm is installed in the mold base 1; Plug gently from the inside to the outside with a soft plug; at the outlet of the tin-bismuth alloy welding wire product 11 out of the mold, plug it gently from the outside to the inside with a soft plug; the cooler 6 uses a blower; the distance between the drawing machine 4 and the stretching mold 2 The distance of the outlet is 120mm. Pour tap water 3 into the middle of the mold base 1 so that the liquid level is always 20mm higher than the entrance and exit of the ...

Embodiment 2

[0053] The difference between this embodiment and Example 1 is that four Sn-57wt%Bi alloy welding wires with a diameter of 1.0 mm were simultaneously prepared on the device of the present invention.

[0054] Install four Φ1.0mm drawing dies 2 on the horizontal line on the mold base 1, and enter the four entrances on the same horizontal line of the mold base 1 on the four volumes of tin-bismuth alloy blanks 9 respectively, and lightly press them from the inside to the outside with a soft plug. Lightly plugged; at the outlet of the four pieces of tin-bismuth alloy welding wire products 11 out of the mold, gently plugged with a soft plug from the outside to the inside; the cooler 6 uses a blower; the distance between the drawing machine 4 and the outlet of the drawing die 2 is 100mm ; The drawing machine is engraved with four stretching grooves corresponding to the die opening; four winding machines are set behind the drawing machine. Pour oil 3 with a high volatility point into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com