Shallow pile jacket structure for offshore booster station

An offshore booster station and jacket technology, which is applied in underwater structures, infrastructure engineering, hydraulic engineering and other directions, can solve the problems of the jacket's low anti-overturning and anti-slip capabilities, poor reliability of grouting connection sections, and pile foundation resistance. Low tensile bearing capacity and other problems, to achieve the effect of being conducive to anti-overturning stability, reducing uneven settlement, and improving vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

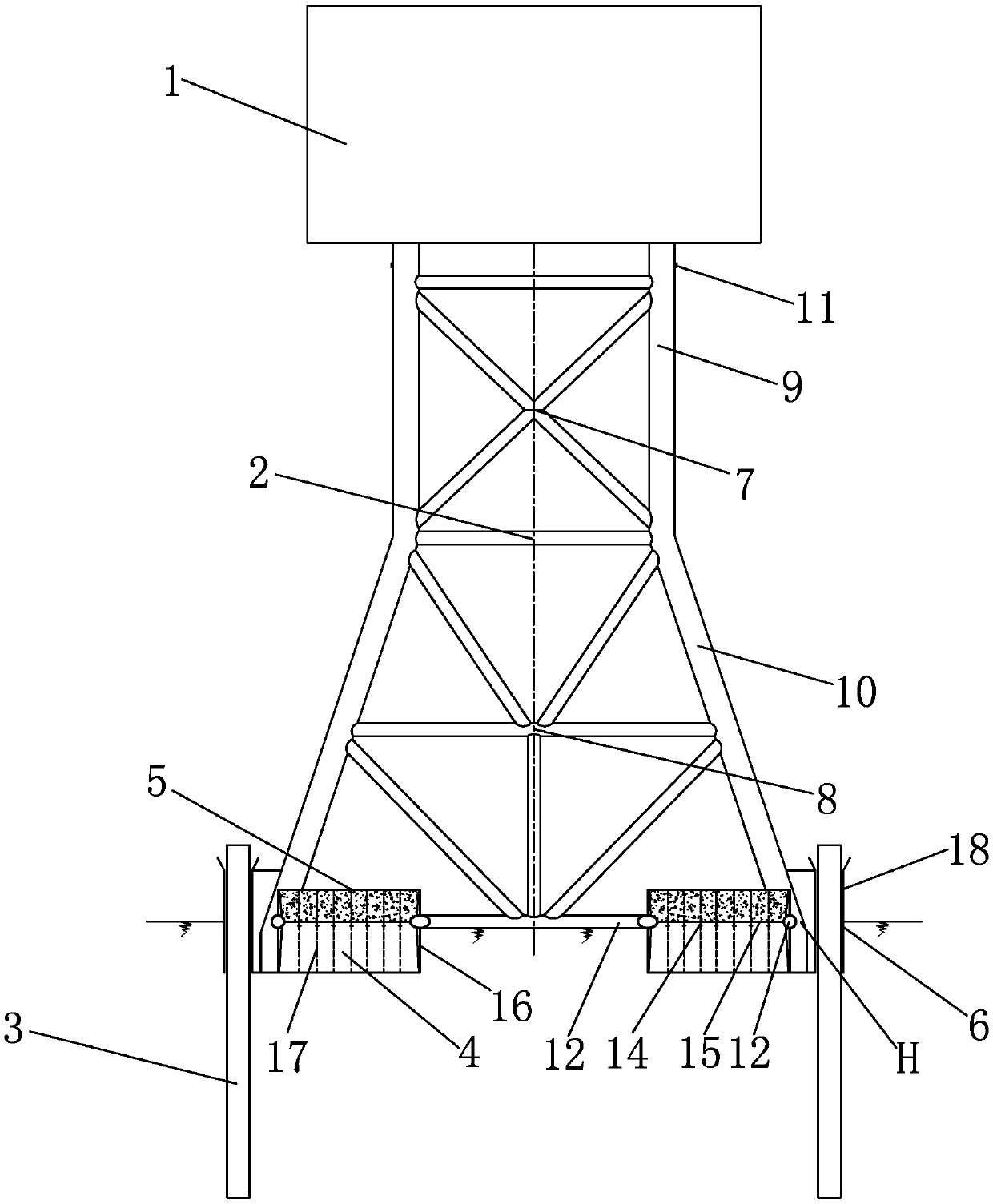

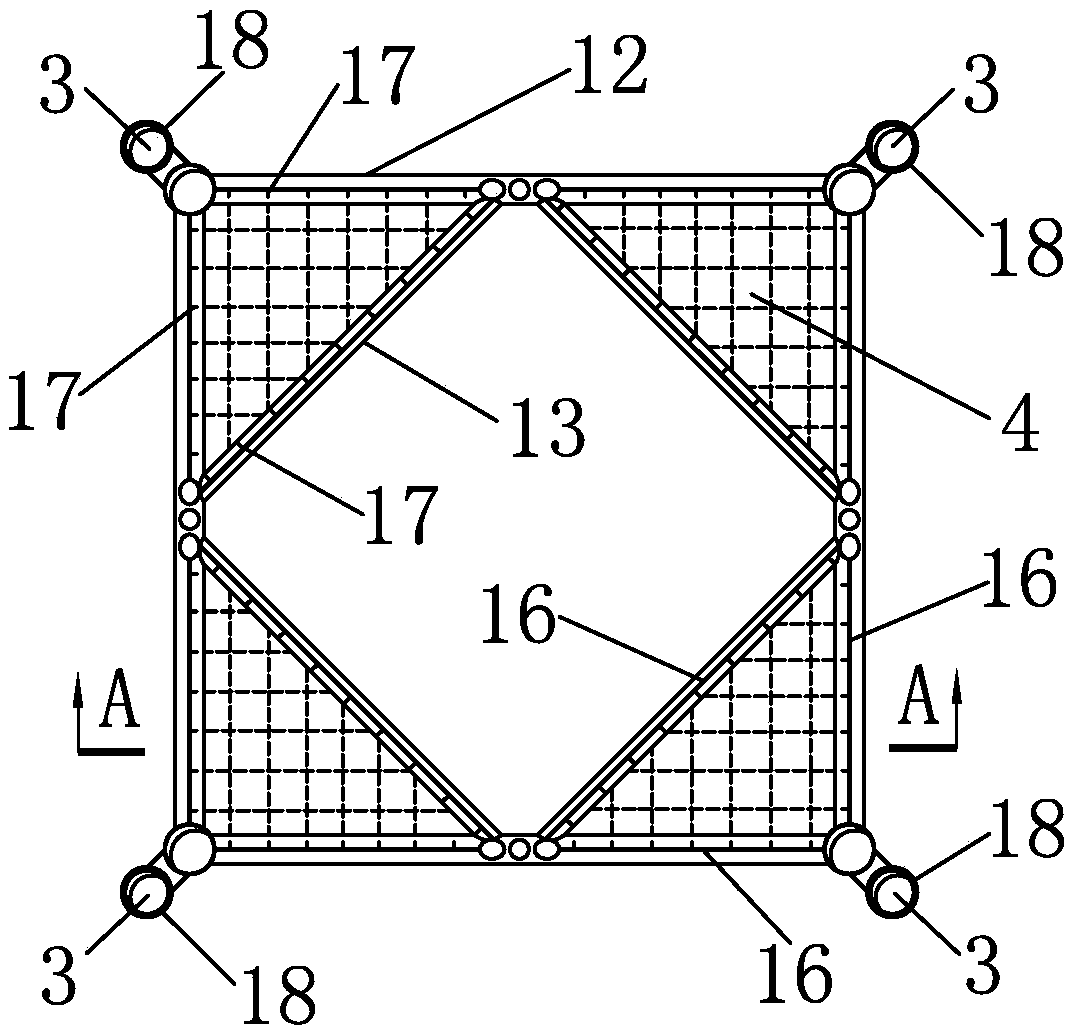

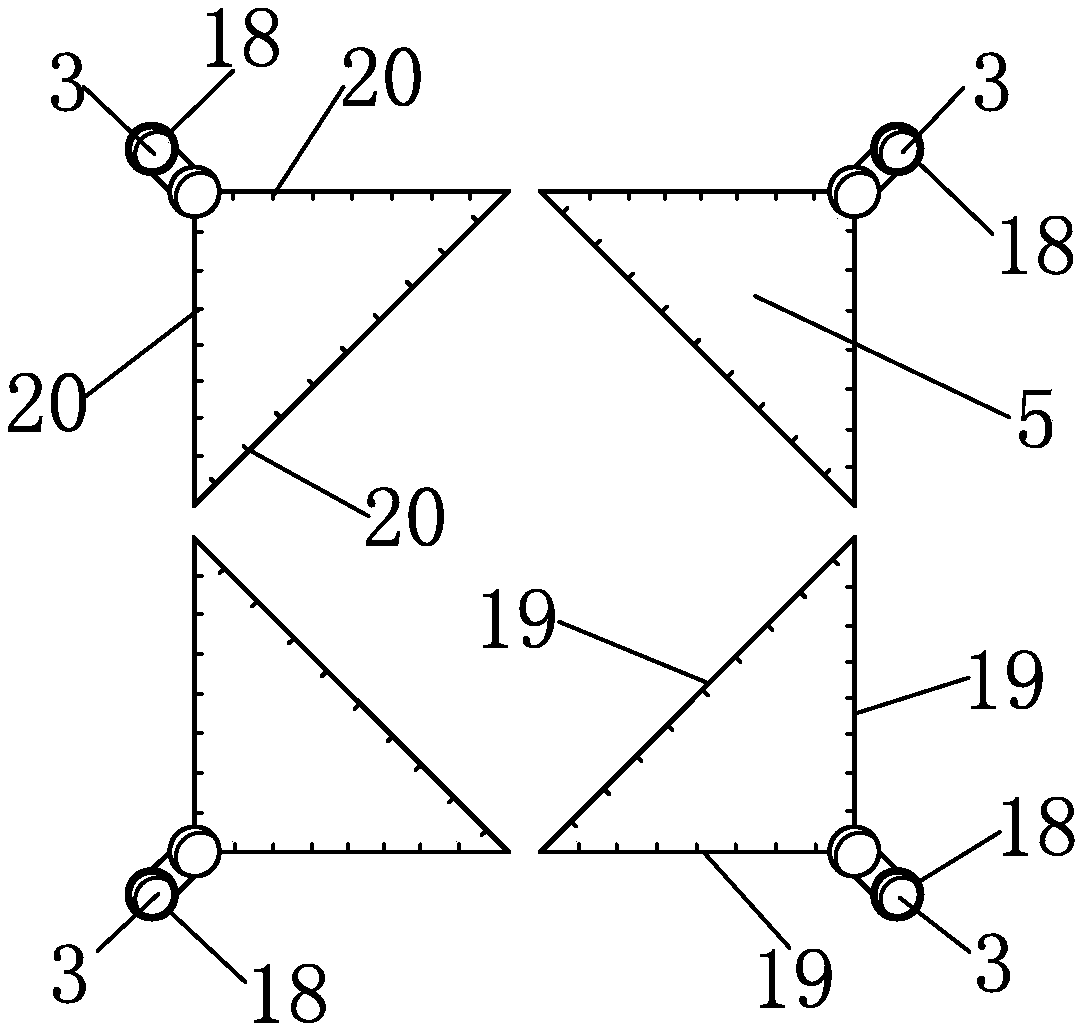

[0031] Such as Figure 1~Figure 5 As shown, this embodiment is an offshore step-up station with a capacity of 300MW. The sea area where the offshore step-up station is located has a water depth of 40m, and there is a relatively thick silt layer on the surface of the seabed cover. The upper platform 1 of the offshore step-up station is an integrally closed structure, and the overall construction is completed on land, and then transported to the sea area of the wind farm for hoisting.

[0032] Such as Figure 1~Figure 5 As shown, in this embodiment, a shallow pile jacket structure used for offshore booster stations includes a large foot jacket 2, a non-rock-socketed short pile 3, an anti-skid box 4, a ballast box 5 and a pressure-resistant type Grouting section 6.

[0033] Such as figure 1 As shown, the large foot jacket 2 is made up of the jacket 7 of the above water part and the jacket 8 of the underwater part. The main conduit 9 of the jacket 7 on the water surface is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com