Feed composite protection type acidulant and production method thereof

An acidifier and protective technology, which is applied in the field of feed compound protective acidifier and its production, can solve the problems of affecting the palatability of feed, effective ingredients with low melting point, affecting the secretion of gastric acid and pepsin, etc., to improve the use value and use Effect, not easy to be volatile and lost, guarantee healthy and complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

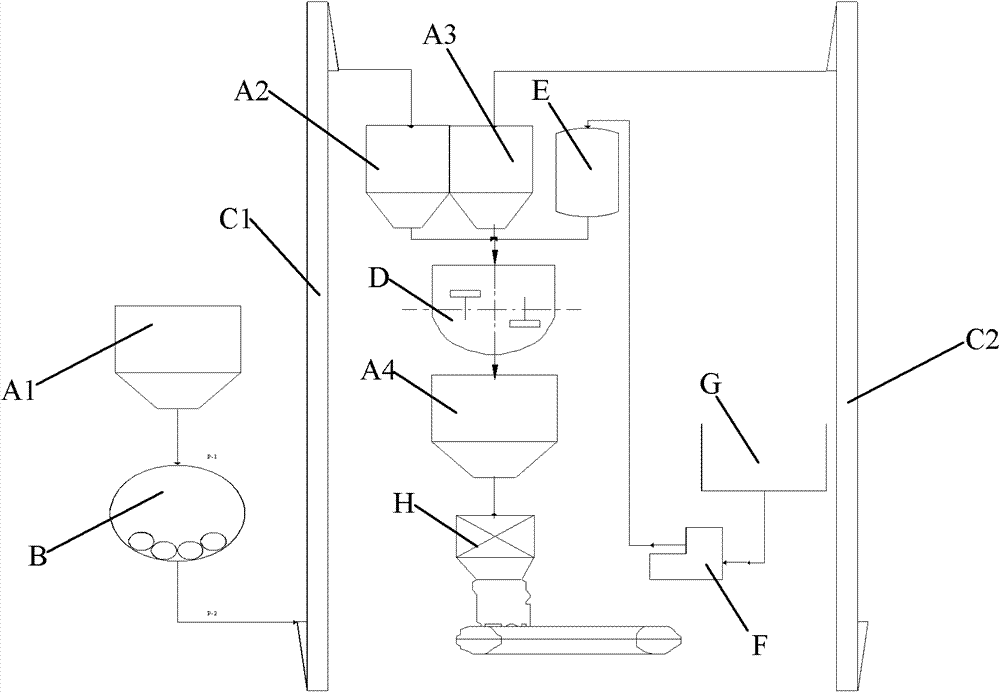

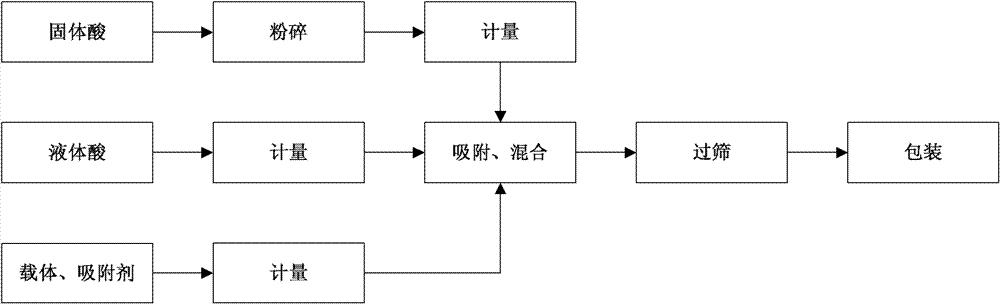

Method used

Image

Examples

example 1

[0082] Acidulant formula: 8% (weight) of phosphoric acid (commercially available, food grade), 12% (commercially available, food grade), 25% (commercially available, food grade) of (weight) fumaric acid (commercially available, feed grade ), 10% (by weight) of malic acid (commercially available, food grade) and 30% (by weight) of stearic acid (commercially available, food grade).

[0083] Process according to the above processing method, wherein the liquid acid is phosphoric acid, the solid acid is citric acid, fumaric acid and malic acid, and the coating material is stearic acid.

example 2

[0085] Acidulant formula: 12% (weight) of phosphoric acid (commercially available, food grade), 10% (commercially available, food grade), 15% (commercially available, food grade) of (weight) fumaric acid (commercially available, feed grade ), 15% (by weight) of malic acid (commercially available, food grade) and 40% (by weight) of stearic acid (commercially available, food grade).

[0086] Process according to the above processing method, wherein the liquid acid is phosphoric acid, the solid acid is citric acid, fumaric acid and malic acid, and the coating material is stearic acid.

example 3

[0088] Acidulant formula: 15% (weight) of phosphoric acid (commercially available, food grade), 20% (commercially available, food grade), 20% (commercially available, food grade) of (weight) fumaric acid (commercially available, feed grade ), 8% (by weight) of malic acid (commercially available, food grade) and 50% (by weight) of stearic acid (commercially available, food grade).

[0089] Process according to the above processing method, wherein the liquid acid is phosphoric acid, the solid acid is citric acid, fumaric acid and malic acid, and the coating material is stearic acid.

[0090] The product appearance of the feed compound protective acidifier of Example 1 manufactured by the above-mentioned equipment and process is: full-pass 20 mesh, 80 mesh sieves are less than 10% white micro-particle products, please refer to Figure 9 shown. The release of active ingredients in the product is as follows: Figure 10 as shown, Figure 10 Shown is the release of feed compound p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com