Groove-shaped channel AlGaN/GaN-reinforced high electron mobility transistor (HEMT) component and manufacturing method thereof

An enhanced, channel technology, applied in the field of microelectronics, can solve the problems of inability to meet the threshold voltage requirements of switching applications, the influence of device performance and reliability, and the low threshold voltage, to eliminate polarization effects and achieve good anisotropy. , the effect of improving electrical characteristics and threshold voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

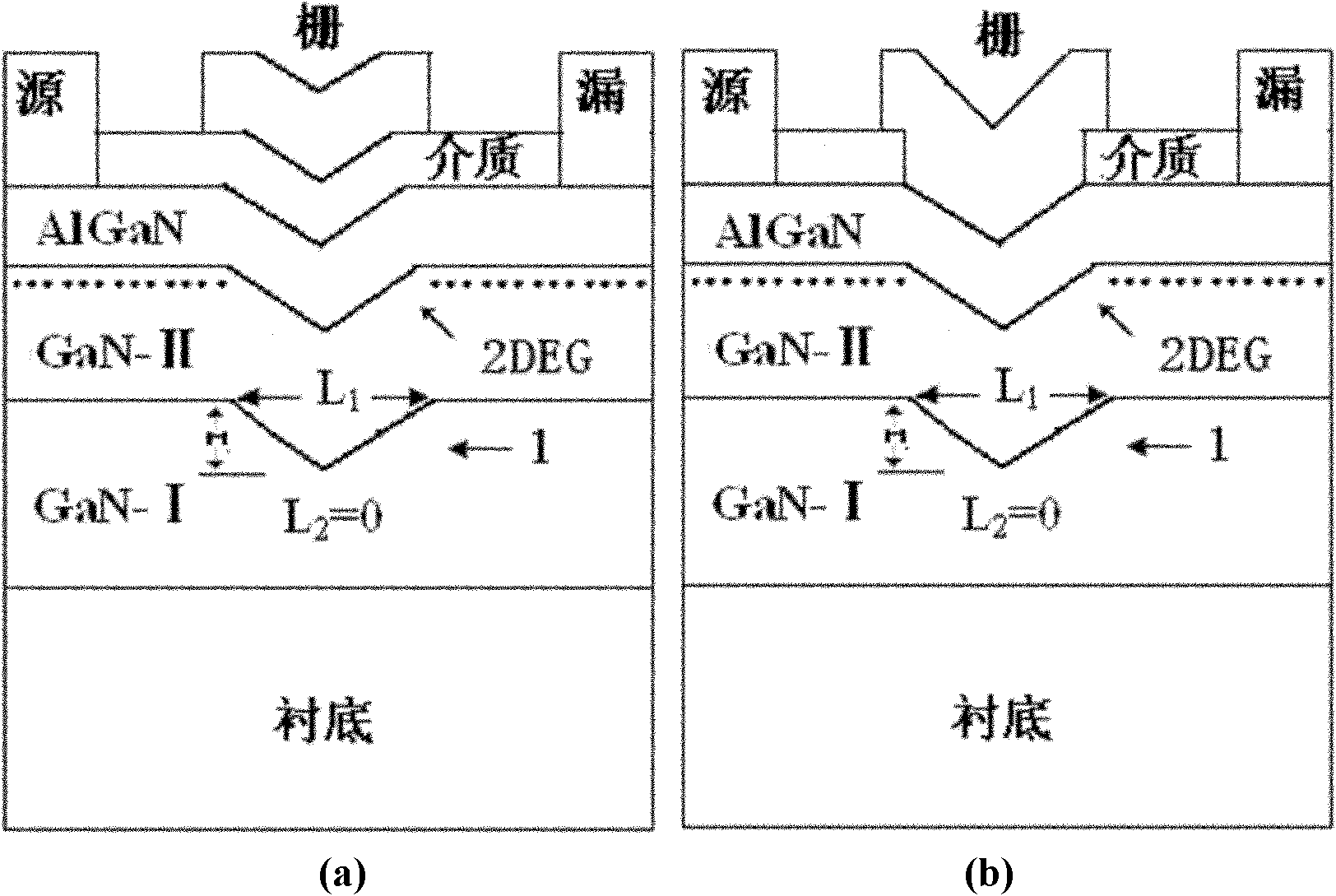

[0058] refer to figure 1 (a), the AlGaN / GaN enhanced MIS gate HEMT device of the present invention, the structure from top to bottom is: substrate, I-GaN layer, II-GaN layer, AlGaN barrier layer, source level, drain electrode, dielectric layer and the gate, wherein the two ends of the barrier layer are the source and the drain, and the middle of the I-GaN layer is provided with a triangular groove (1), the depth of the groove: H is 100-600 nanometers, which is less than the thickness of I-GaN , the length of the upper base of the groove is L 1 , the value ranges from 0.1 to 0.5 microns, and the length of the lower bottom is L 2 = 0, two-dimensional electron gas 2DEG is formed on the plane interface of II-GaN and AlGaN, and the concentration of 2DEG is very low or almost non-existent on the inclined interface of II-GaN and AlGaN, and the dielectric layer is located on the upper part of the source and drain and the upper part of the barrier layer between the source and the dra...

Embodiment 2

[0060] refer to figure 1 (b), the AlGaN / GaN enhanced MS gate HEMT device of the present invention, the structure is from top to bottom: substrate, I-GaN layer, II-GaN layer, AlGaN barrier layer, source, drain, dielectric Layer and gate, wherein the two ends of the barrier layer are source and drain, and a triangular groove (1) is arranged in the middle of the I-GaN layer. The depth of the groove: H is 100-600 nanometers, which is less than the thickness of I-GaN , the length of the upper base of the groove is L 1 , the value ranges from 0.1 to 0.5 microns, and the length of the lower bottom is L 2 = 0, two-dimensional electron gas 2DEG is formed on the plane interface of II-GaN and AlGaN, and the concentration of 2DEG is very low or almost non-existent on the inclined interface of II-GaN and AlGaN, and the dielectric layer is located between the source and the drain The upper part of the potential barrier layer, the gate is located between the upper part of the potential bar...

Embodiment 3

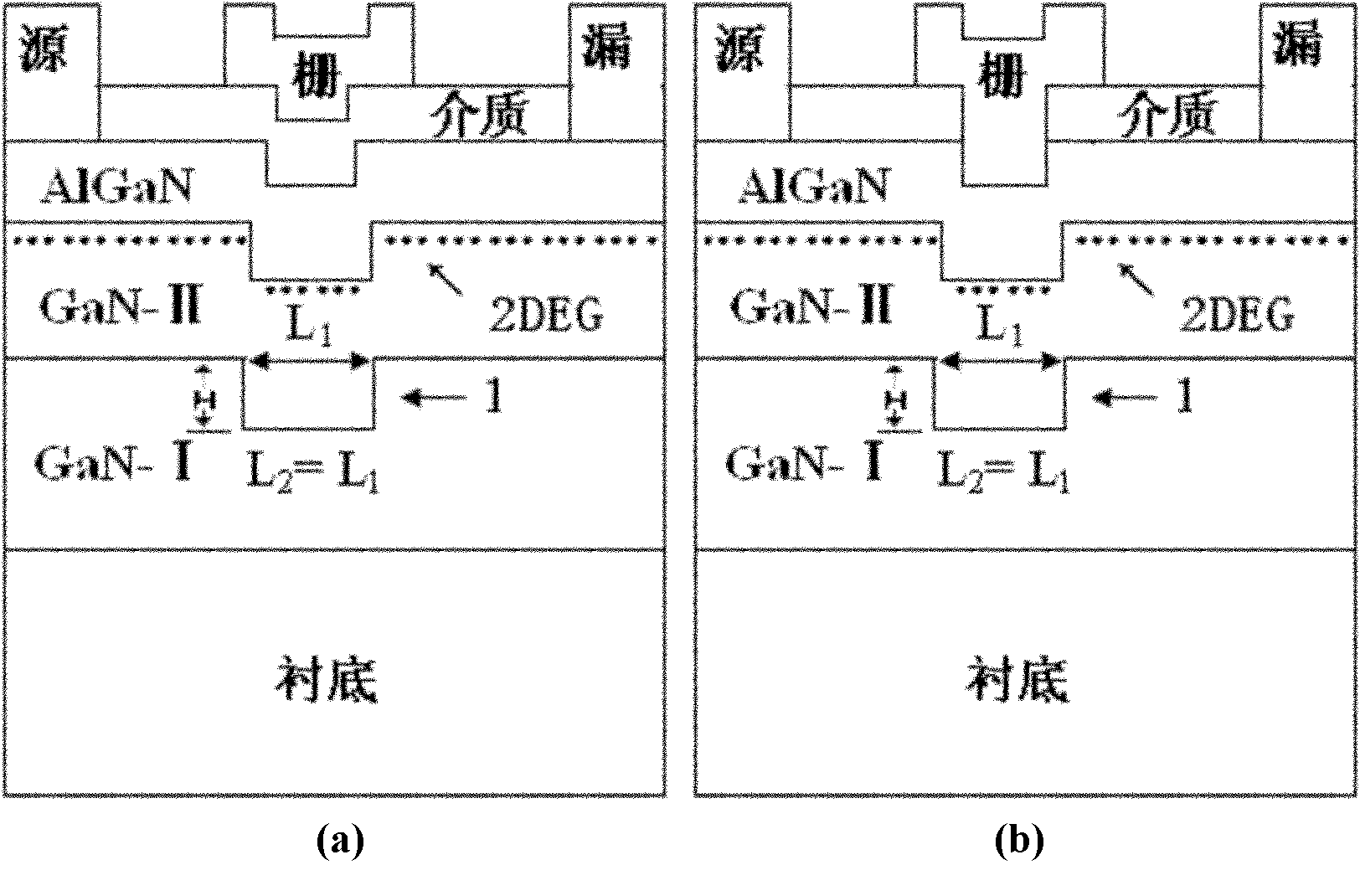

[0062] refer to figure 2 (a), AlGaN / GaN enhanced MIS gate HEMT device, the structure from top to bottom is: substrate, I-GaN layer, II-GaN layer, AlGaN barrier layer, source, drain, dielectric layer and gate The two ends of the barrier layer are the source and the drain, and a rectangular groove (1) is arranged in the middle of the I-GaN layer. The depth of the groove: H is 100-600 nanometers, which is less than the thickness of the I-GaN. The length of the upper base is L 1 , the value ranges from 0.1 to 0.5 microns, and the length of the lower bottom is L 2 =L 1 , a two-dimensional electron gas 2DEG is formed on the plane interface of II-GaN and AlGaN, and the concentration of 2DEG is very low or almost non-existent on the vertical interface of II-GaN and AlGaN, and the dielectric layer is located on the upper part of the source and drain and the source The upper part of the barrier layer between the electrode and the drain, and the gate is located on the upper part of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com