Electrophoretic display device and method for manufacturing thereof

An electrophoretic display and gate electrode technology, which is applied to identification devices, circuits, electrical components, etc., can solve the problems of reduced yield, high cost, complex semiconductor film processes, etc., and achieves light weight, high electrical characteristics, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

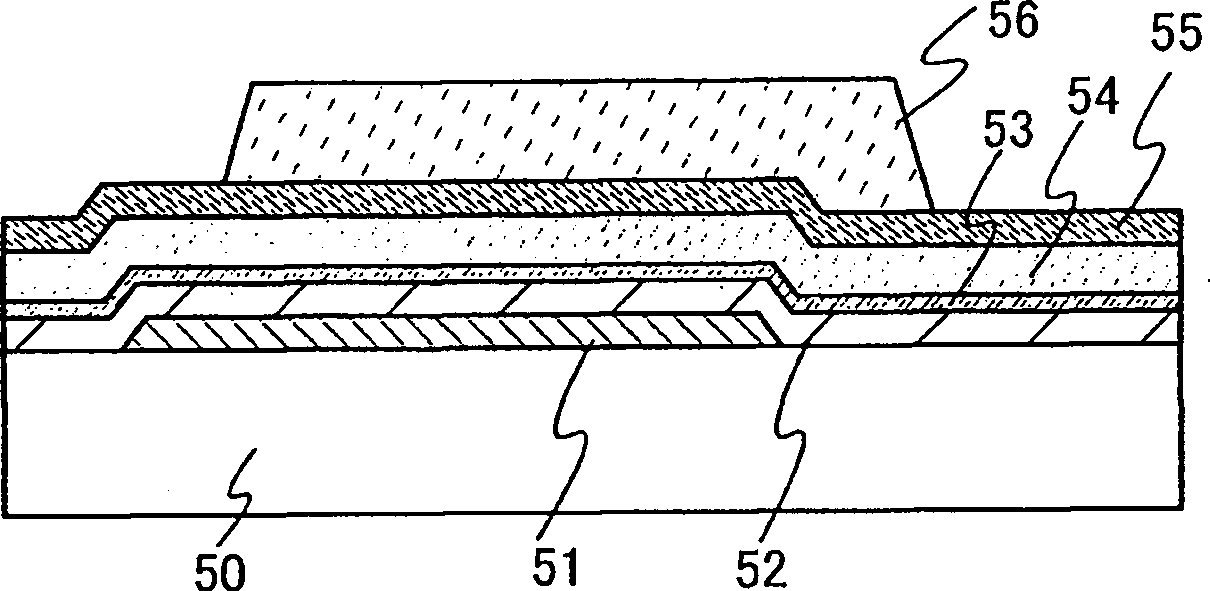

[0033] In this embodiment, refer to Figure 1A to Figure 6C The manufacturing process of an electrophoretic display device, especially the manufacturing process of a pixel having a thin film transistor will be described. Figure 1A to Figure 3B is a cross-sectional view showing a manufacturing process of a thin film transistor, Figure 4 It is a figure explaining the electrophoretic display element, Figure 5A to Figure 5B It is a plan view and its vertical cross-sectional view showing a connection region of a thin film transistor and a pixel electrode in a pixel. FIG. 6 is a diagram showing the appearance of an electrophoretic display device.

[0034] An n-channel type thin film transistor having a microcrystalline semiconductor film is more preferably used for a driving circuit because its mobility is higher than that of a p-channel type thin film transistor having a microcrystalline semiconductor film. It is preferable to make the polarity of all the thin film transistor...

Embodiment approach 2

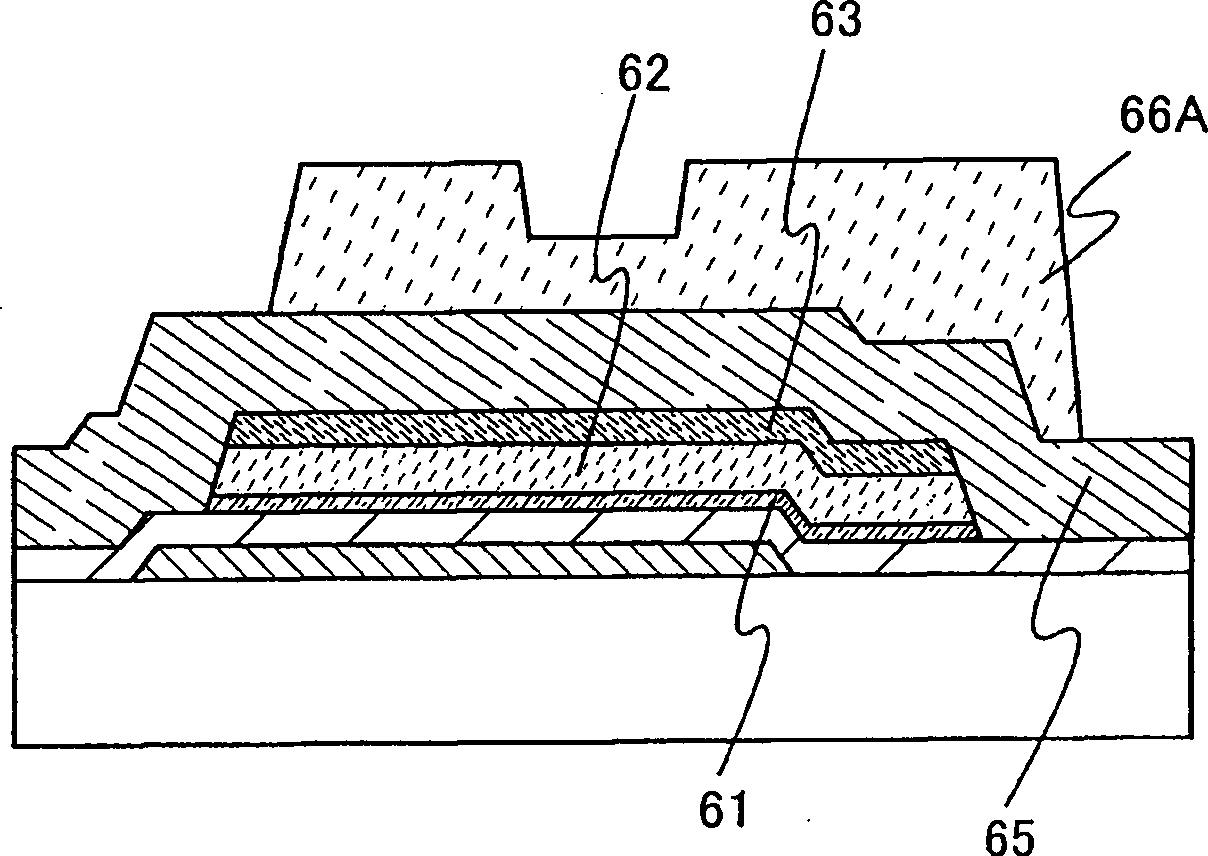

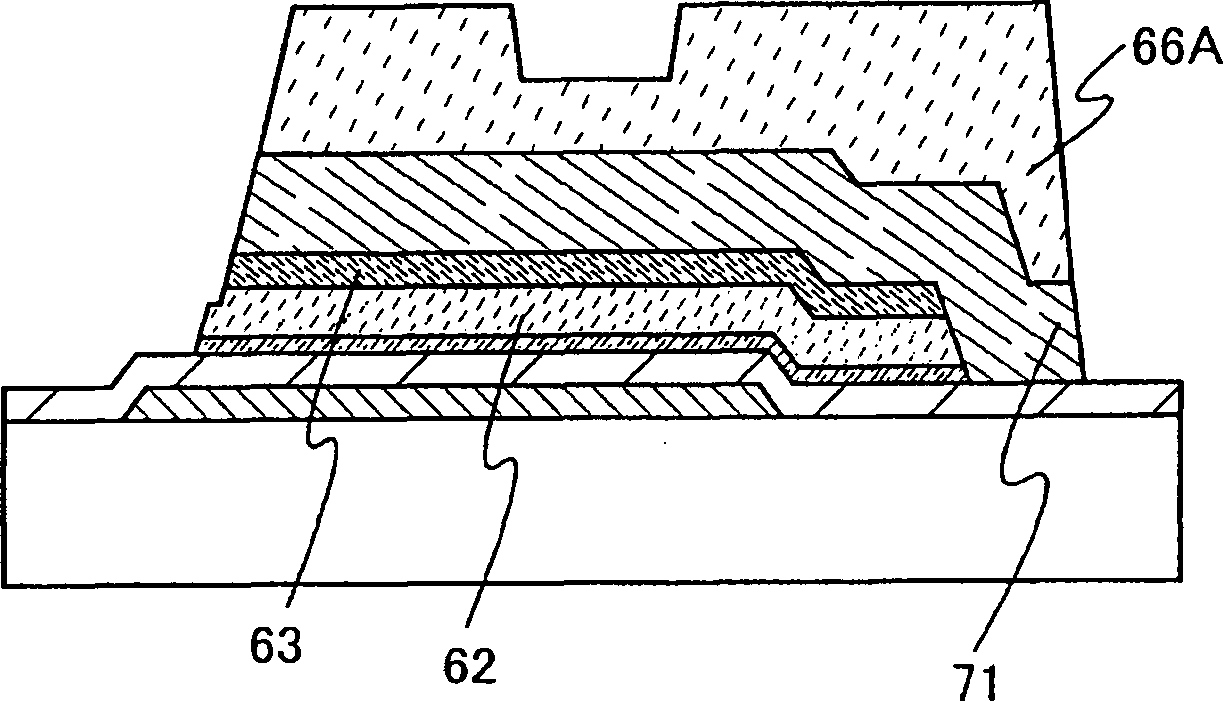

[0094] In this embodiment mode, manufacturing processes different from those of the electrophoretic display device shown in Embodiment Mode 1 will be described with reference to FIGS. 7A to 8B .

[0095] First, a molybdenum film 702 is formed on a support substrate 701 . A glass substrate, a ceramic substrate, or a quartz substrate can be used as the supporting substrate 701 . In this embodiment mode, a glass substrate is used. In addition, as the molybdenum film 702, a molybdenum film of 30 nm to 200 nm formed by a sputtering method is used. Since the substrate sometimes needs to be fixed in the sputtering method, thickness unevenness of the molybdenum film near the edge of the substrate tends to occur. Therefore, it is preferable to remove the molybdenum film near the edge by dry etching.

[0096] Next, the surface of the molybdenum film 702 is oxidized to form a molybdenum oxide film 703 . As a method for forming the molybdenum oxide film 703, the surface of the molybde...

Embodiment approach 3

[0111] In this embodiment mode, the appearance and cross section of the electrophoretic display device of the present invention will be described with reference to FIGS. 9A and 9B . 9A and 9B are diagrams of an electrophoretic display device in which a thin film transistor 4010 having a microcrystalline semiconductor film formed on a first flexible substrate 4001 and an electrophoretic display element are sealed with a sealing material 4005 between the second flexible substrate 4006. 4008. Fig. 9B corresponds to a cross-sectional view along line A-A' of Fig. 9A.

[0112] A sealing material 4005 is provided to surround the pixel portion 4002 and the scanning line driver circuit 4004 formed on the first flexible substrate 4001 . In addition, a second flexible substrate 4006 is provided on the pixel portion 4002 and the scanning line driver circuit 4004 . Therefore, the pixel portion 4002 and the scanning line driver circuit 4004 are sealed together with the electrophoretic dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com