Segmental capacitor type continuous liquid level sensor

A liquid level sensor, capacitive technology, applied in the field of sensors, can solve the problems of increasing the difficulty of liquid level measurement, and achieve the effect of increasing the liquid level measurement range, improving measurement accuracy, and improving measurement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

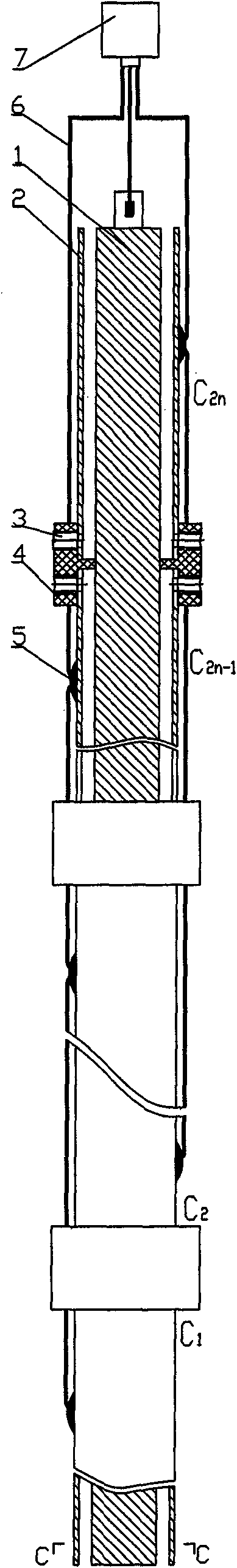

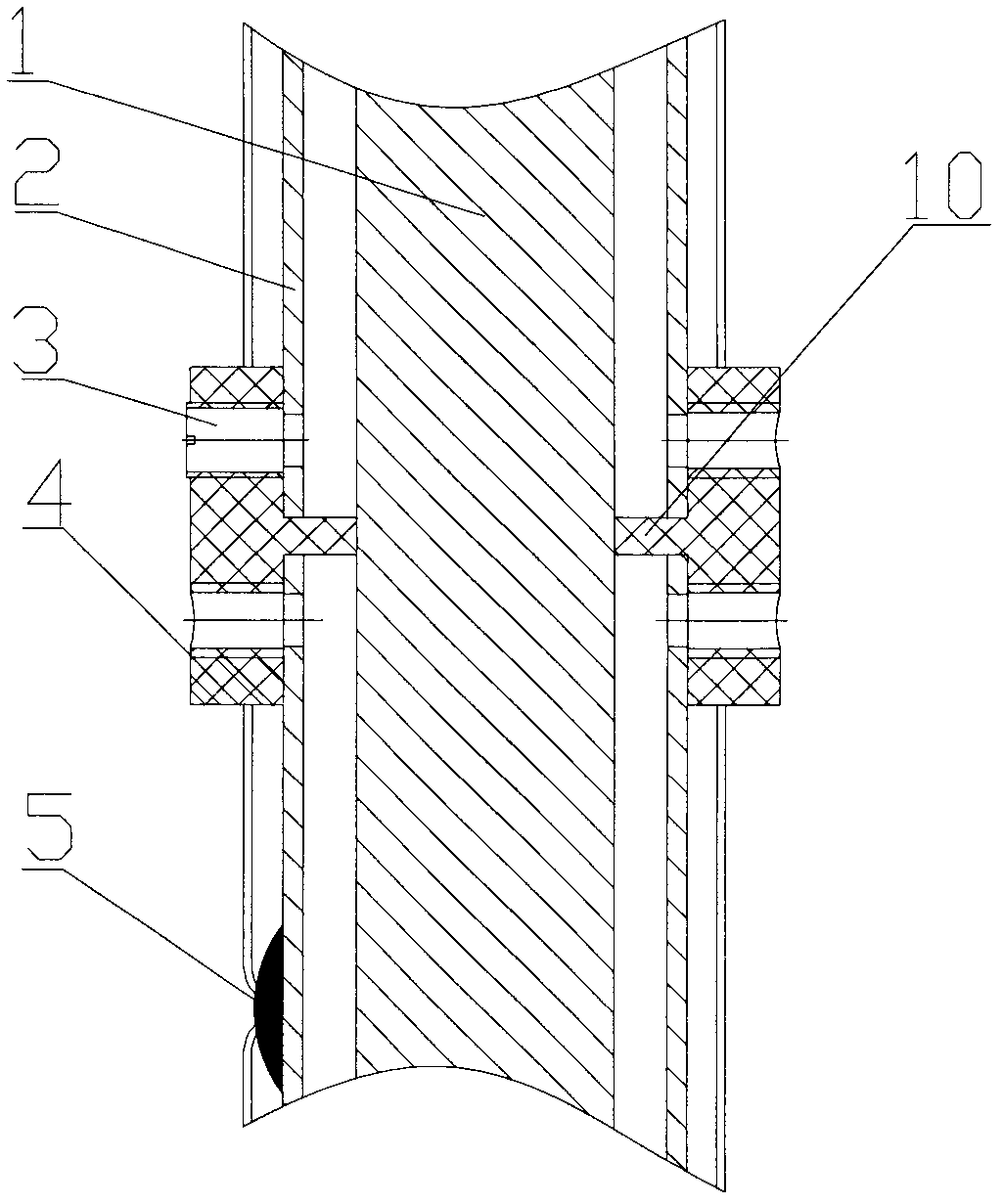

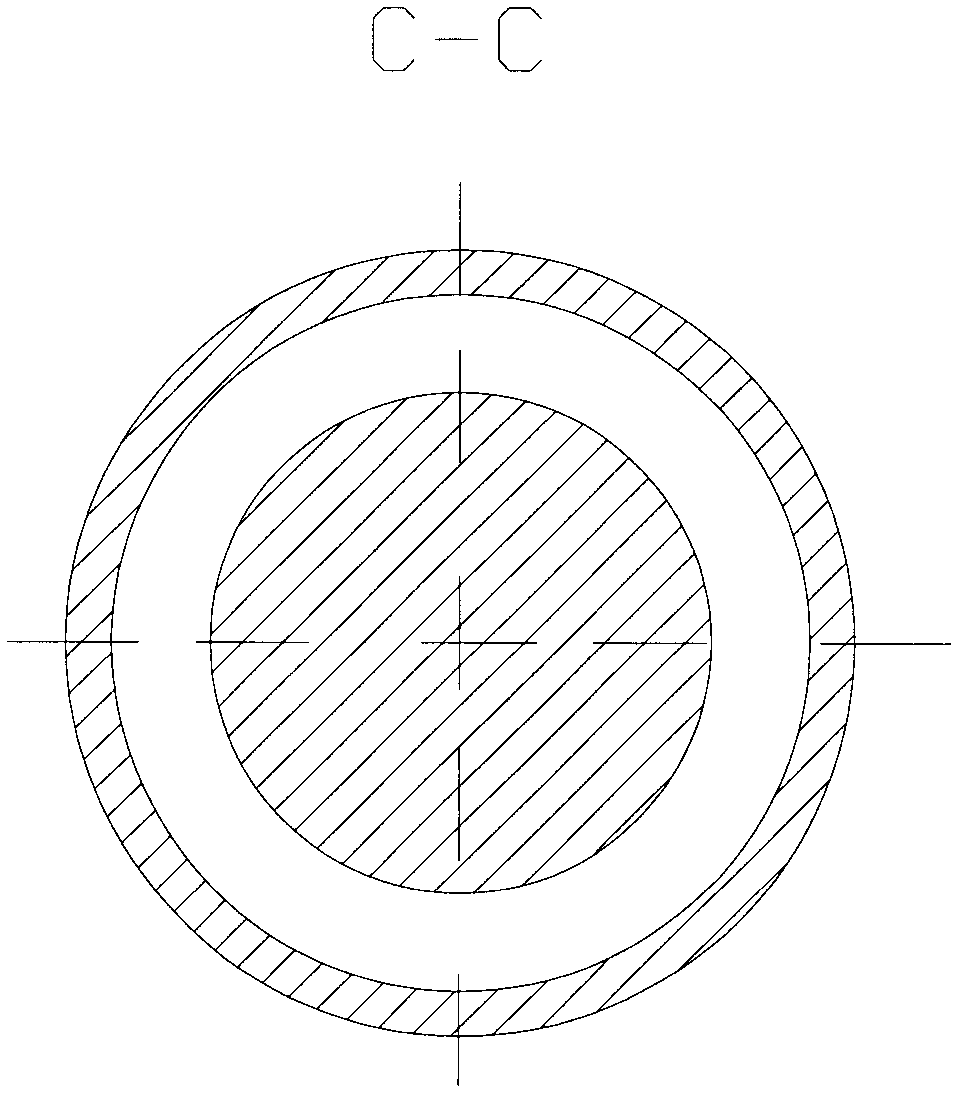

[0032] Such as figure 1 Shown is a schematic structural diagram of the sensor of the present invention. It can be seen from the figure that the sensor of the present invention includes an inner electrode 1, an outer electrode 2, a connecting bush 4, a welding piece 5 and a cable 6, and the inner electrode 1 and the outer electrode 2 are the same metal material, the outer electrode 2 has a relatively large inner diameter and relatively short length, while the inner electrode 1 has a relatively small outer diameter and relatively long length. The inner electrode 1 and the outer electrode 2 are installed concentrically, and the ring between them forms a ring capacitor. The number of the external electrodes 2 of the segmental capacitive sensor is an even number, and the number is set to 2N. In this embodiment, N is set to 5, and there are 10 extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com