Gas-slag separation and recovering system for drilling construction

A technology for separation and recovery of drilling rigs, which is applied to drilling equipment and methods, earthwork drilling, drilling equipment, etc. It can solve problems such as gas rise in the working space, construction drilling shutdown, gas accidents, etc., so as to improve operating efficiency and ensure The effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

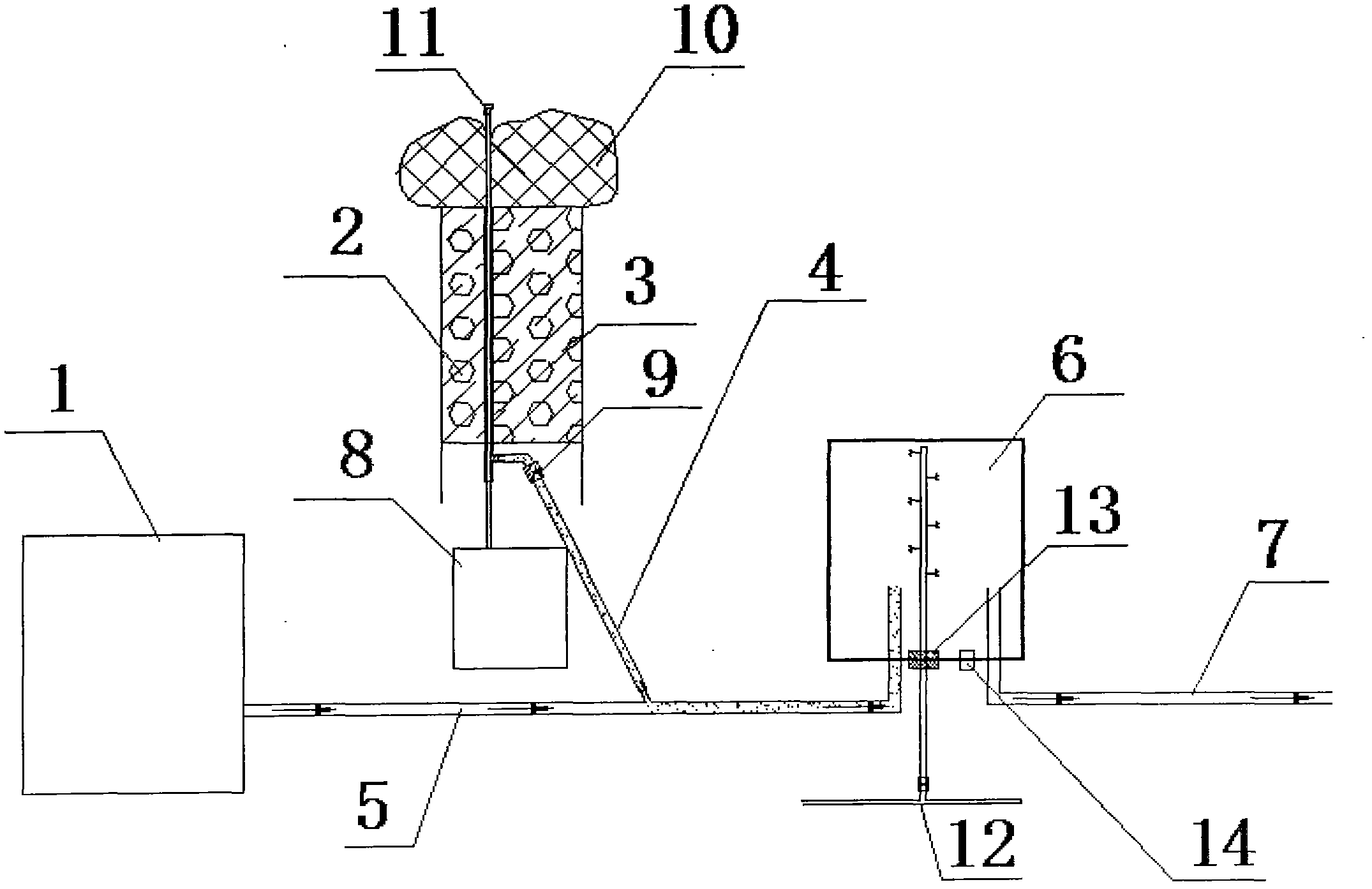

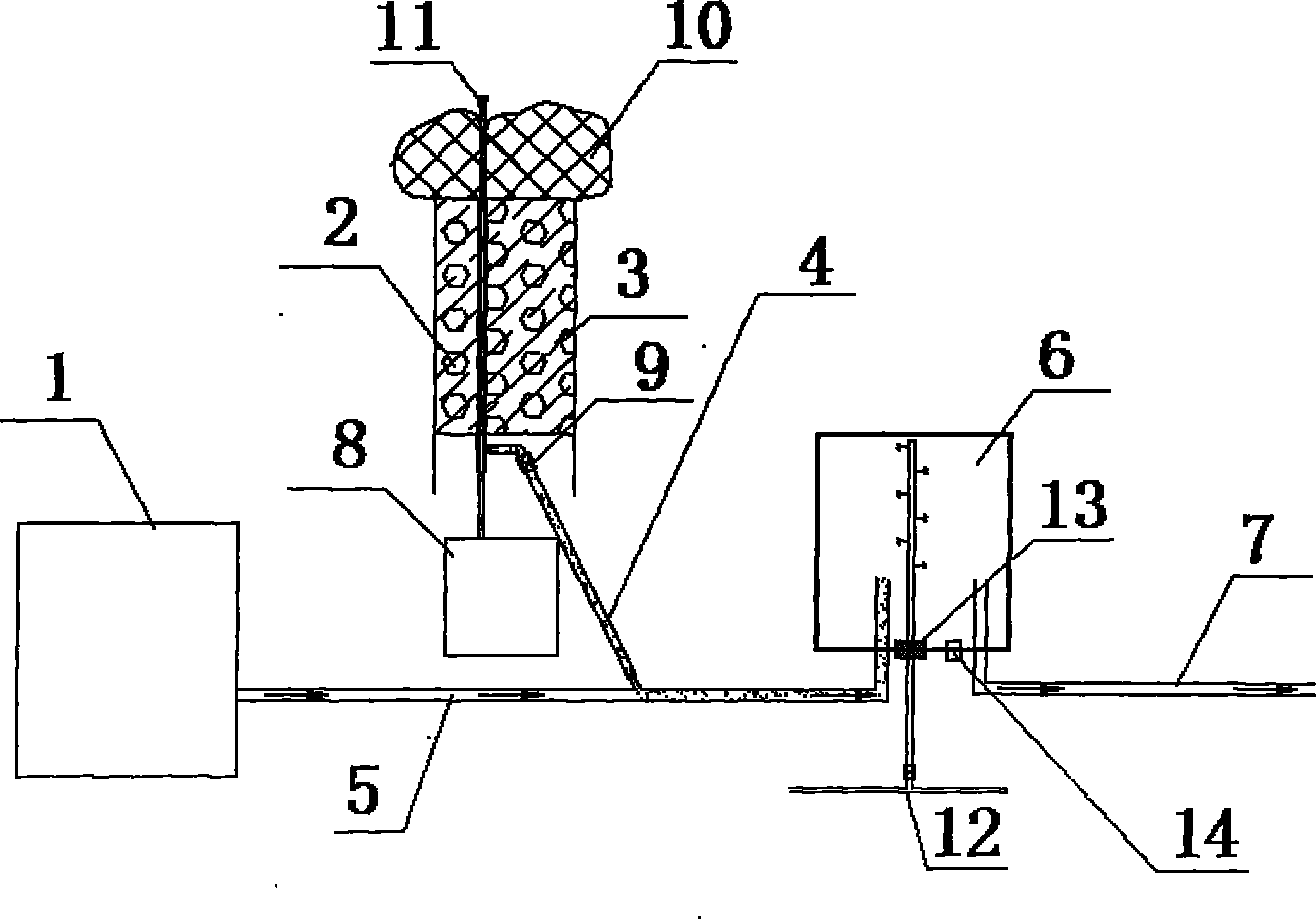

[0014] As shown in the drawings, the present invention includes a drilling rig 8 and a sprinkler and dust prevention system 12, and is characterized in that the drill pipe 11 of the drilling rig 8 is set with a three-way sealer 3, and the three-way sealer 3 is connected with a connecting pipe 4 , the connecting pipe 4 is connected with a conveying pipeline 5 through a three-way pipe, and the connecting pipe 4 is provided with a throttle valve 9 for controlling the flow of cuttings to ensure that the conveying pipeline 5 will not be blocked due to excessive cuttings. One end of the air blower 1 is connected, the other end of the conveying pipeline 5 is connected with a closed space 6, and the other end of the closed space 6 is connected with a negative pressure drainage pipe 7 connected with the ground gas drainage system, and the closed space 6 is installed with a useful Sprinkler and dust prevention system 12 and slag discharge door 13 for separating cuttings.

[0015] The th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com