Lithium aluminum alloy for secondary lithium battery and manufacturing method thereof

A secondary lithium battery, lithium-aluminum alloy technology, applied in the field of chemical power storage, can solve the problem of no electrochemical performance synthesis process development and other problems, achieve strong lithium ion supply capacity, reduce polarization, easy to operate and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

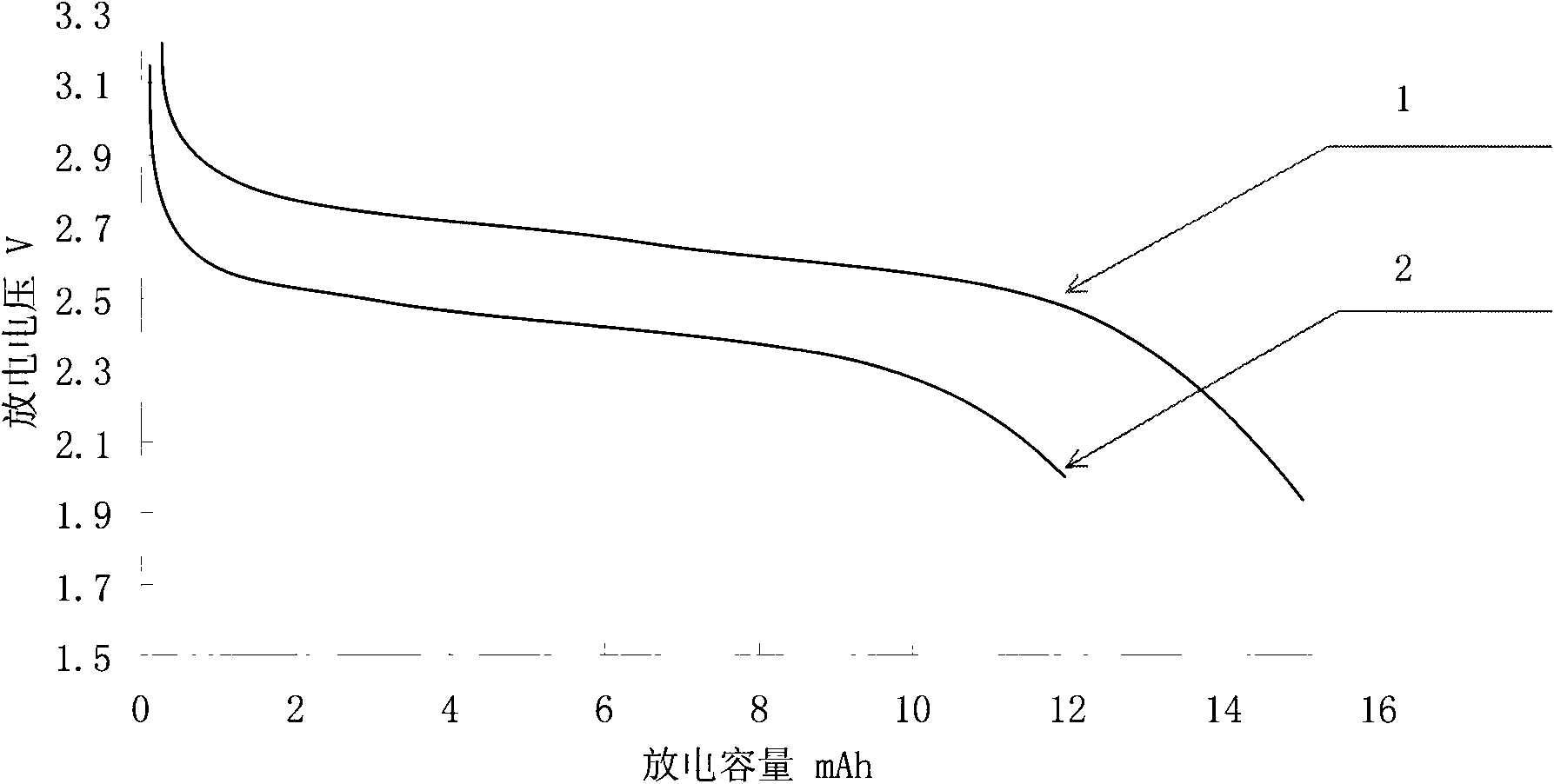

Image

Examples

Embodiment 1

[0018] In dry air with a relative humidity below 0.5%, put 11g of lithium particles with a diameter of 1mm and a purity of 99.5% and 89g of metallic aluminum particles with a diameter of 0.04mm and a purity of 99.9% into a 500ml ceramic grinding jar, and add 10 diameter 20mm corundum balls, then cover the lid, fill with 99.99% argon, install it on a ball mill and mill it at a speed of 20 rpm for 10 hours, stop the ball milling and take out the mixture, pick out the corundum balls, take 60mg of the mixture and pour it into the inner diameter In a mold with a diameter of 9.4mm, pressurize the powder with a pressure of 5Mpa on the hydraulic press, then remove the mold, take out the cake with a thickness of 0.4mm and a diameter of 9.4mm, and then put the cake into the grinding mouth wide Mouth bottle, add 1M LiClO Electrolyte in 1:3 (mass ratio) PC and DME, seal and soak for 56 hours, take out and wash 3 times with analytical pure DMC, dry to obtain lithium aluminum alloy.

[0019...

Embodiment 2

[0023] In dry air with a relative humidity below 2%, put 20g of lithium particles with a diameter of 1mm and a purity of 99.1% and 80g of metallic aluminum particles with a diameter of 0.1mm and a purity of 99.9% into a 500ml ceramic grinding jar, and add 10 diameter 20mm corundum balls, then cover the lid, fill with 99.99% argon, put it on a ball mill and mill it at a speed of 50 rpm for 3 hours, stop the ball milling and take out the mixture, pick out the corundum balls, take 60mg of the mixture and pour it into the inner diameter In a mold with a diameter of 9.4mm, pressurize the powder with a pressure of 5Mpa on the hydraulic press, then remove the mold, take out the cake with a thickness of 0.4mm and a diameter of 9.4mm, and then put the cake into the grinding mouth wide Mouth bottle, add 1M LiPF6 electrolyte solution in 1:3 (mass ratio) PC and DME, seal and soak for 206 hours, take out and wash 3 times with analytical pure PC, dry to obtain lithium aluminum alloy.

Embodiment 3

[0025] In dry air with a relative humidity below 1%, put 15g of lithium particles with a diameter of 1mm and a purity of 99.4% and 85g of metallic aluminum particles with a diameter of 0.08mm and a purity of 99.9% into a 500ml ceramic grinding jar, and add 10 diameter 20mm corundum balls, then cover the lid, let in 99.99% argon gas, install it on a ball mill and mill it at a speed of 100 rpm for 30 minutes, stop the ball milling and take out the mixture, pick out the corundum balls, take 50mg of the mixture and pour it into the inner diameter In a mold with a diameter of 9.4mm, pressurize the powder with a pressure of 5Mpa on the hydraulic press, then remove the mold, take out the cake with a thickness of 0.4mm and a diameter of 9.4mm, and then put the cake into the grinding mouth wide Add 1M LiBF4 electrolyte solution in 1:3 (mass ratio) EC and DMC, seal and soak for 206 hours, take it out and wash it with analytical pure PC for 10 times, blow dry to obtain lithium aluminum al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com