Zirconium phosphate-based luminescent material as well as preparation method and application thereof

A luminescent material, zirconium phosphate technology, applied in luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of poor color purity, low luminous efficiency, poor chemical stability, etc., and achieve high luminous intensity and variable luminous color. Tuning, luminous spectrum adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] a) Weighing Y 2 o 3 (99.99%) 0.038 gram, be dissolved in the 1mol / L dilute nitric acid solution of 5ml, take by weighing 0.071 gram of citric acid and dissolve in this solution as complexing agent, after stirring at room temperature for 30 minutes, adjust the pH value of the solution with ammoniacal liquor to 5~6;

[0050] b) Weigh ZrOCl 2 ·8H 2 O (analytical pure) 0.645 grams, be dissolved in 20ml deionized water, add 0.841 grams of citric acid as complexing agent, after stirring at room temperature for 30 minutes, adjust the pH value of the solution to 7~8 with ammonia water;

[0051] c) mix the two solutions obtained by steps a) and b), and stir to make them uniform;

[0052] d) Add ammonium dihydrogen phosphate (NH 4 h 2 PO 4 , analytically pure) 0.345 g, stirred to form a transparent solution;

[0053] e) Dry the transparent solution obtained in step d) at 80-100°C to form a gel, then raise the temperature to 180-300°C to form an airgel, put the obtained ai...

Embodiment 2

[0057] a) Weigh La(OH) 3 (99.99%) 0.063 gram, be dissolved in the 1mol / L dilute nitric acid solution of 5ml, take by weighing 0.071 gram of citric acid and dissolve in this solution as complexing agent, after stirring at room temperature for 30 minutes, adjust the pH value of the solution with ammoniacal liquor to 5~6;

[0058] b) Weigh ZrOCl 2 ·8H 2 O (analytical pure) 0.645 grams, be dissolved in 20ml deionized water, add 0.841 grams of citric acid as complexing agent, after stirring at room temperature for 30 minutes, adjust the pH value of the solution to 7~8 with ammonia water;

[0059] c) mix the two solutions obtained by steps a) and b), and stir to make them uniform;

[0060] d) adding diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 , analytically pure) 0.396 g, stirred to form a transparent solution;

[0061] e) Dry the transparent solution obtained in step d) at 80-100°C to form a gel, then raise the temperature to 180-300°C to form an airgel, put the obtained ...

Embodiment 3

[0065] Weigh Gd 2 o 3 (99.99%) 0.060 gram, be dissolved in the 1mol / L dilute nitric acid solution of 5ml, all the other contents are with described in embodiment 1 or 2.

[0066] The white product obtained is Gd 0.33 Zr 2 (PO 4 ) 3 Material.

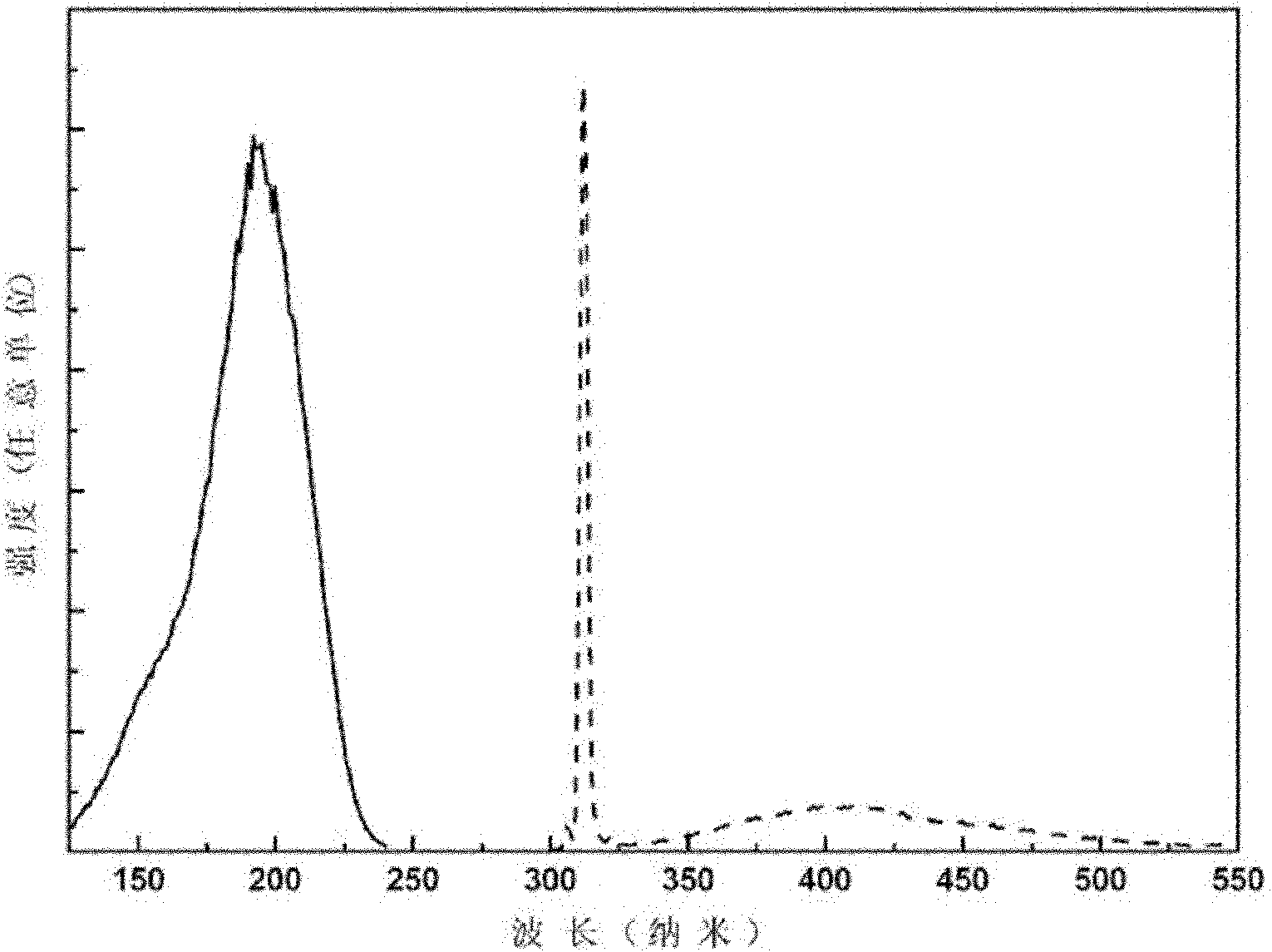

[0067] image 3 For the prepared Gd of this embodiment 0.33 Zr 2 (PO 4 ) 3 The excitation spectrum (solid line) and the emission spectrum (dashed line) of the material sample monitored at 312nm wavelength and the emission spectrum (dashed line) monitored at 200nm wavelength at room temperature, represented by image 3 Visible: the Gd that the present embodiment makes 0.33 Zr 2 (PO 4 ) 3 The material is a self-excited blue-white light-emitting material with an emission peak around 400nm, and is a good VUV blue-white light-emitting material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com