Polyacrylamide microgel as well as preparation method and application thereof

A polyacrylamide and acrylamide technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problem that polyacrylamide oil displacement agent has small particle size, cannot block large pores in oil reservoirs, and is not suitable for oil reservoirs. and other problems, to achieve the effect of good oil displacement effect, large particle size and reduction of industrial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

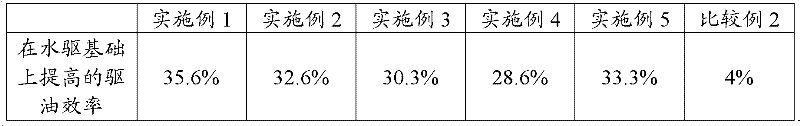

Examples

Embodiment 1

[0025] 30 parts by weight of Span80 and 300 parts by weight of white oil were mixed at 45° C. to 50° C. to obtain a mixed solution 1, which was cooled to room temperature.

[0026] At room temperature, 15 parts by weight of sodium acrylate, 5 parts by weight of sodium 2-acrylamido-2-methylpropanesulfonate, 55 parts by weight of acrylamide, 1 part by weight of N, N'-methylenebisacrylamide and 1 part by weight Parts of potassium persulfate were mixed with 150 parts by weight of distilled water to obtain mixed solution 2.

[0027] Add mixed solution 2 dropwise to mixed solution 1 at room temperature at a stirring speed of 120 rpm, then raise the temperature to 70°C, stir for 1 hour, stop heating, and continue stirring at this stirring speed for 1 hour to obtain polyacrylamide micro Gel, observed under an electron microscope, the polyacrylamide microgel is spherical, and the particle size is 30-110 microns.

Embodiment 2

[0029] 0.3 parts by weight of Span80 and 40 parts by weight of white oil were mixed at 45° C. to 50° C. to obtain a mixed solution 1, which was cooled to room temperature.

[0030] At room temperature, 2 parts by weight of sodium acrylate, 2 parts by weight of sodium 2-acrylamido-2-methylpropanesulfonate, 6 parts by weight of acrylamide, 0.025 parts by weight of N, N'-methylenebisacrylamide and 0.1 parts by weight Parts of ammonium persulfate were mixed with 20 parts by weight of distilled water to obtain mixed solution 2.

[0031] Add the mixed solution 2 dropwise to the mixed solution 1 at room temperature at a stirring speed of 70 rpm, then raise the temperature to 70°C, stir for 1 hour, stop heating, and continue stirring at the stirring speed for 1 hour to obtain polyacrylamide micro Gel, observed under an electron microscope, the polyacrylamide microgel is spherical, and the particle size is 30-150 microns.

Embodiment 3

[0033] 6 parts by weight of Span80 and 120 parts by weight of white oil were mixed at 80° C. to 100° C. to obtain a mixed solution 1, which was cooled to room temperature.

[0034] At room temperature, mix 15 parts by weight of sodium acrylate, 2 parts by weight of N-vinylpyrrolidone, 6 parts by weight of acrylamide, 0.05 parts by weight of N, N'-methylenebisacrylamide and 1 part by weight of potassium persulfate with 40 parts by weight of distilled water Mix to obtain mixed solution 2.

[0035] Add mixed solution 2 dropwise to mixed solution 1 at room temperature at a stirring speed of 80 rpm, then raise the temperature to 80°C, stir for 1 hour, stop heating, and continue stirring at this stirring speed for 1 hour to obtain polyacrylamide micro Gel, observed under an electron microscope, the polyacrylamide microgel is spherical, and the particle size is 30-150 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com